Introduction to Impedance Control Concept

To distinguish the resistance of direct current (DC), the resistance encountered by alternating current is called impedance (Z0), which includes resistance (R), inductive impedance (XC), and capacitive impedance (XL).

Special impedance is also known as "special impedance". It refers to the resistance experienced by high-frequency signals or electromagnetic waves in a transmission signal line (i.e. copper wire of the circuit board we manufacture) relative to a reference layer (i.e. shielding layer, suggestion layer, or reference layer) during widespread propagation at a certain frequency, which is called characteristic impedance. It is actually a vector of electrical impedance, inductive impedance, and capacitive impedance.

The significance of controlling special impedance PCB

PCB not only functions as an electronic product for current conduction, but also plays a role in signal transmission:

The high frequency and high speed requirements of electronic products require the performance of the circuit supplied by the PCB to ensure that the signal does not reflect during transmission, maintaining the integrity and distortion of the signal;

Special impedance is the core of solving signal integrity problems;

When electronic devices (such as computers, communication switches, etc.) are working, the signal emitted by the driver must reach the receiver through the PCB signal line. To ensure signal integrity, the special impedance (Z0) of the PCB signal line must match the "electronic impedance" of the head and tail components;

When the transmission line is greater than or equal to one-third of the rise time length, the signal will be reflected and special impedance issues must be considered.

Factors affecting specific impedance properties

The dielectric constant of a medium is inversely proportional to the resistance value (Er) of a specific property. The following figure shows the parameters of the common sense sheet:

The dielectric thickness between the circuit layer and the ground layer (or outer layer) is directly proportional to the characteristic impedance value (H). The following figure shows the normal sheet parameters:

Impedance line bottom width (lower end W1): Line surface width (upper end W2), inversely proportional to characteristic impedance.

Copper thickness is inversely proportional to the specific resistance value (T)

Distance between adjacent lines and special impedance value (differential impedance) (S)

Directly proportional, the thickness of the solder mask layer on the substrate is inversely proportional to the impedance value (C)

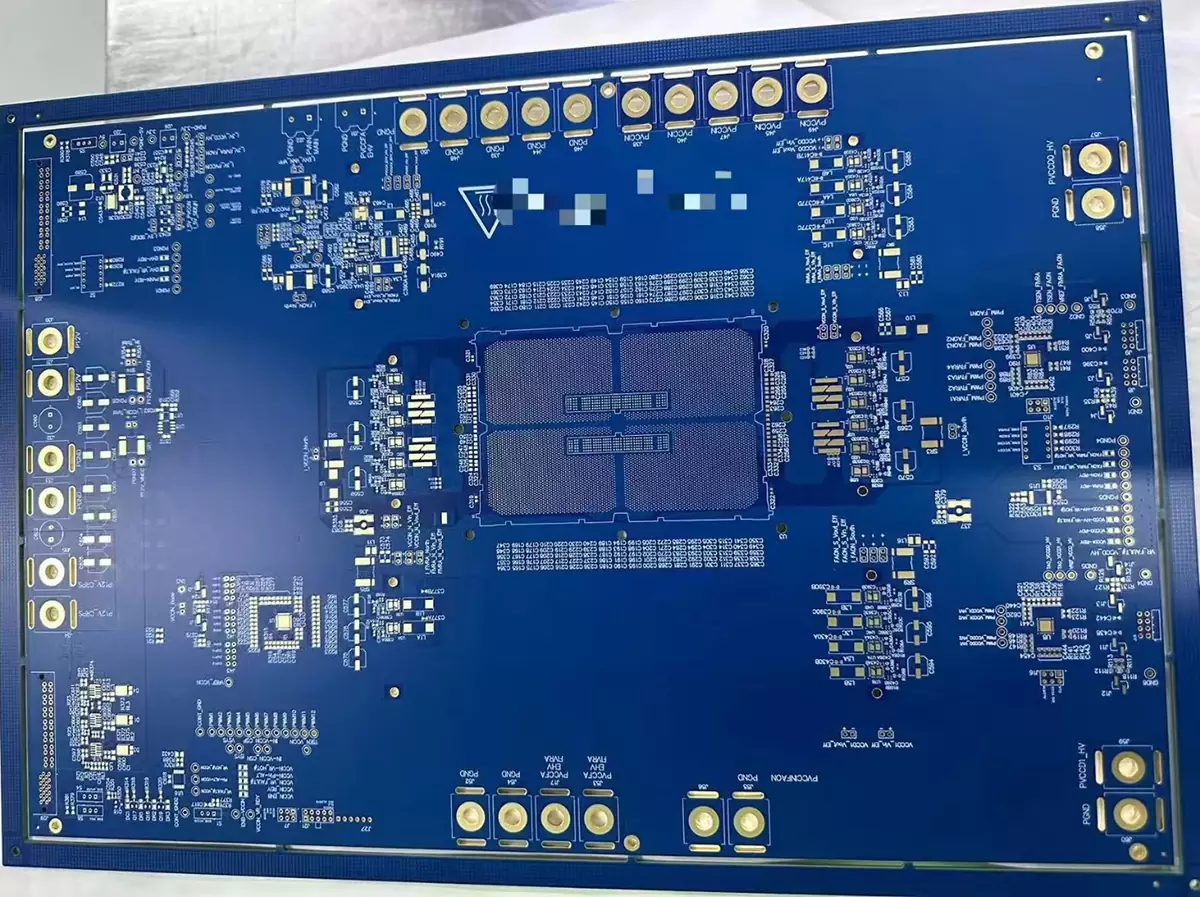

PCB

Process factors affecting PCB impedance

Due to corrosion, the impedance is greatly affected when the copper thickness is 2oz, and it is generally impossible to control the impedance.

The layer blank without copper wire by default needs to be supplemented with a curing film during production. When calculating impedance, the dielectric thickness provided by the sheet supplier cannot be directly used as a substitute. It is necessary to subtract the cured film to supplement these vacancies. This is also one of the main reasons why the impedance I calculated myself is not completely the same as the final result from the manufacturer.

PCB impedance

The calculation of impedance is quite complex and tedious, but we can summarize some empirical values to help improve the calculation speed. For commonly used FR4 and 50 ohm microstrip lines, the line width is usually equal to twice the thickness of the dielectric; For a 50 ohm strip line, the line width is equal to half of the total thickness of the medium between the two simplest surfaces, which can help us quickly lock in the line width range. Note that the line width calculated by ordinary calculations is less valuable than this.

In addition to improving calculation speed, we also need to improve calculation accuracy. Do you often encounter situations where the impedance calculated by yourself is not exactly the same as the impedance calculated by the board manufacturer? Some people may directly say that this has nothing to do with the board factory. But has there been a situation where the board factory's adjustment was inadequate, causing you to relax impedance management control? To make a good product, it's best to take control of everything in your own hands.

The following items are for your reference:

a、 The line width is relatively wide, not thin. What's the meaning of this? Since we know there are fine limitations in the manufacturing process, there is no limit to the width. If you encounter limits in order to adjust impedance and fine tune linewidth, it will be troublesome. Either increase costs or relax impedance management control. So in the calculation, relative width means that the target impedance is slightly lower. For example, if the impedance of a single wire is 50 ohms, we can calculate it as 49 ohms. Try not to calculate up to 51 ohms.

The Bay Group has flashed a development direction. There may be multiple impedance management control purposes in our preset, so this group should be too large or too small, rather than 100 ohms being too large and 90 ohms being too small.

c、 Consider residual copper rate and adhesive flow issues. When there are etched lines on one or both sides of the prepreg, the adhesive will fill the etched holes during the pressing process, so the thickness of the adhesive between the two layers will decrease. The smaller the residual copper rate, the more filling there will be. The rest is less. So if you need a pre impregnated material thickness of 5ml between the two layers, you should choose a thicker pre impregnated material based on the residual copper rate.

d. Specify the glass cloth and adhesive content. Engineers who have read the sheet data sheet know that the dielectric constant of different glass cloths, semi cured sheets, or core boards with different adhesive contents varies, and even if the heights are almost the same, they may differ by 3.5 and 4. This difference can cause a single line impedance change of approximately 3 ohms. The additional glass fiber effect is closely related to the window volume of the glass cloth. If you preset 10Gbps or higher and your laminated board does not specify the material, and the PCB factory uses a single 1080 material, it may expose signal integrity issues.