How to design an electrical panel?

For an electrical design engineer, electrical design is a daily job. How did our electronic design begin?

1. Functional requirements proposed by customers

Before starting to design the electronic panel, we need to clarify the functions that the control board needs to achieve. This includes but is not limited to input signal processing, output signal control, data processing and communication. Clarifying the functional requirements helps us to select appropriate hardware and software, and design corresponding circuits and programs.

2. Select appropriate electronic components

According to the functional requirements, we need to select the appropriate hardware. This includes microcontroller, sensor, actuator, power module, communication module, etc. When selecting hardware, you need to consider its performance, reliability, ease of use, cost and other aspects. At the same time, compatibility and connection mode between hardware should also be considered.

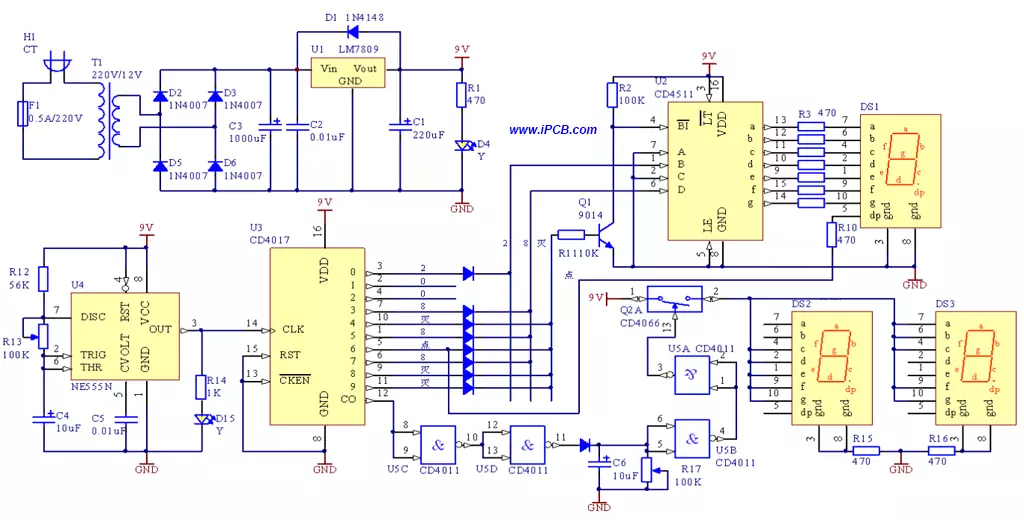

3. The electronic engineer starts to design the circuit

Circuit design is the core part of electronic panel design. Its purpose is to reasonably connect the selected electronic components with circuit boards to achieve the required functions. In the process of circuit design, it is necessary to consider power distribution, signal direction, component layout, wiring mode and other factors to make the designed circuit board work stably and reliably.

PCB Circuit Board

4. Programming and debugging of PCBA board

Programming and debugging are the key steps to realize the functions of the electronic control board. According to the functional requirements and circuit design, we need to write corresponding programs to control the work of the microcontroller and other hardware. After the program is written, debugging is required to ensure that the program can work normally and meet the design requirements.

5. Reliability design required

Reliability design is to ensure the stability and reliability of the electronic panel. This includes the reliability design of hardware and software. Hardware reliability design can be realized by selecting high-quality electronic components and optimizing circuit design. Software reliability design can be realized through redundancy design, fault detection and recovery.

6. Safety design

The safety design is to ensure the safety of the electronic control panel during use. This includes electrical safety, mechanical safety, environmental safety and other aspects. In the design, equipment grounding, overload protection, lightning protection and other aspects need to be considered to ensure the safety of equipment and personnel.

7. Box build assembly cost control

Cost control is one of the important factors to be considered in the design of electronic control panel. On the premise of meeting functional and performance requirements, reducing costs as much as possible can improve the competitiveness of products. Cost control can be achieved by optimizing hardware and software design and selecting components with high cost performance.

8. User interface design

User interface design is one of the important factors to be considered in the design of electronic control panel. A good user interface can improve the ease of use and user experience of the device. In the design, it is necessary to consider the operation mode, display mode, human-computer interaction and other aspects of the equipment, so that users can easily use the equipment. At the same time, it is also necessary to consider the beauty and style of the user interface to improve the overall quality of the product.

Electronic Design

Electronic design plays a very important role in today's science and technology industry. Whether consumer electronics, communication equipment or medical equipment, high-quality electronic design services are needed to ensure the performance and reliability of products.

iPCB has a professional design team and advanced EDA tools. Our electronic design services include: PCB design, PCB layout, embedded system design, and electrical solutions.

We focus on one-stop electronic design business and manufacturing services, and provide comprehensive services such as design and development, SMT manufacturing, component procurement, plug-in post welding, reliability test and assembly, etc. according to customer's customized needs.