FPC (Flexible Printed Circuit) is a type of printed circuit board (PCB) that uses a flexible substrate, allowing it to bend and flex.

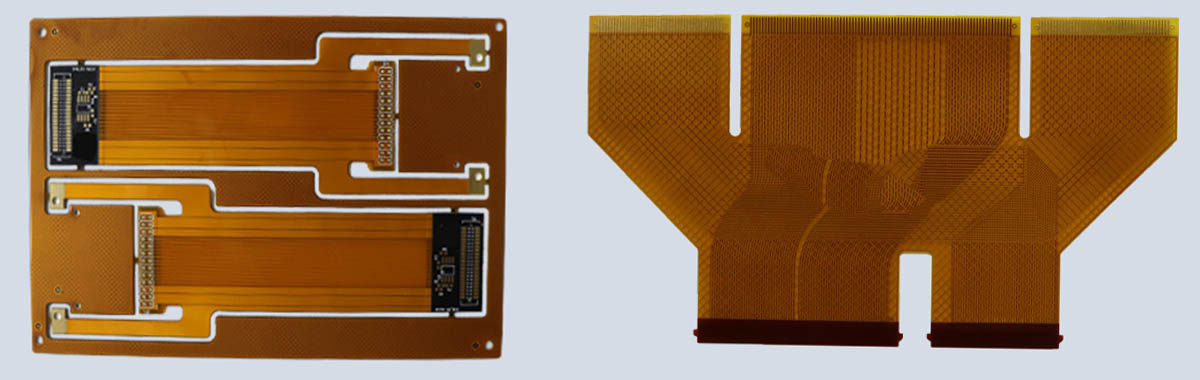

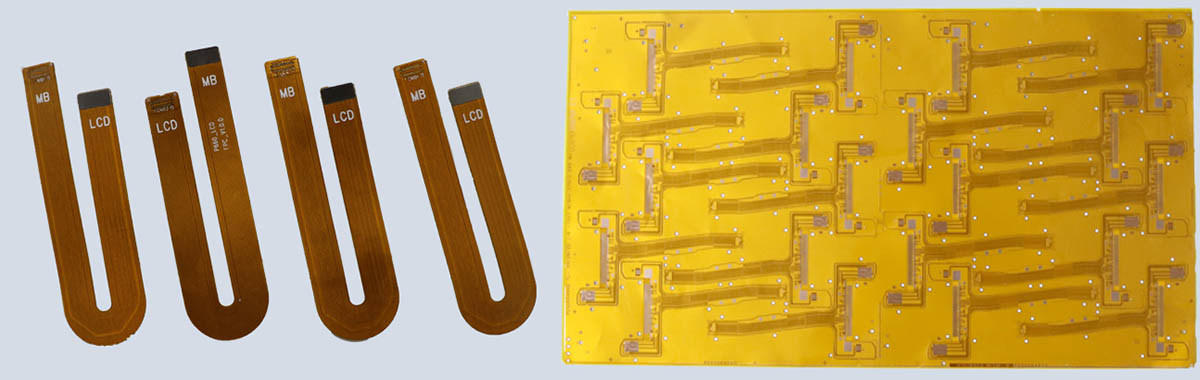

FPC board cutting

The materials used in flexible PCB are basically rolls. Since not all processes must be processed by tape and roll process, the FPC board process must be cut into thin sheets for processing, such as drilling metallized holes of double-sided flexible PCB, which can only be drilled in thin sheets at present. Holes, so the first process of double-sided flexible PCB is to cut the material.

The flexible copper clad laminate has extremely low resistance to external forces and is easily injured. If it is damaged during the cutting process, it will seriously affect the qualified rate of subsequent processes. Therefore, even if it seems to be a very simple cutting, in order to ensure the quality of the material, it must be given enough attention. If the quantity is relatively small, a manual shearing machine or a roller can be used, or an automatic shearing machine can be used for large-scale shearing.

Whether it is single-sided, double-sided copper foil laminate or lamination, the accuracy of the cutting size can reach ±0.33. The opening reliability is high, and the opened materials are automatically stacked neatly, without the need for personnel to collect materials at the exit. By changing the size of the feed roller, the damage to the material can be controlled to a minimum, and the material has almost no wrinkles and scars. In addition, the latest equipment can also automatically cut etched flexible PCBs through the tape and reel process. Optical sensors can detect corrosion positioning patterns and perform automatic cutting and positioning. The cutting accuracy is 0.3mm, but the frame of this cutting material is used as positioning for subsequent processes.

FPC board

FPC board drilling

The through holes of flexible PCBs can also be drilled by CNC like rigid PCB circuit boards, but they are not suitable for hole processing of double-sided metallized hole circuits on tape and tape. Due to the high density of circuit patterns, small diameter of metallized holes, and the limitation of CNC drilling diameter, many new drilling technologies have been put into practical application. These new drilling technologies include plasma etching, laser drilling, micro-hole punching, chemical etching, etc. Compared with CNC drilling, these drilling technologies are more likely to meet the hole forming requirements of tape and reel processes.

CNC drilling

Most drilling on double-sided flexible PCBs is still performed using CNC drilling machines. CNC drilling machines are basically the same as those used on rigid PCB circuit boards, but the drilling conditions are different. Since flexible PCBs are very thin, multiple overlapping holes can be drilled. If the drilling conditions are good, 10 to 15 sheets can be overlapped for drilling. The back plate and cover plate can be made of paper-based phenolic laminate or glass fiber cloth epoxy laminate, or aluminum plate with a thickness of 0.2 to 0.4 mm can be used. There are drill bits for flexible PCBs on the market, and drill bits for drilling holes in rigid PCB circuit boards and milling cutters for milling shapes can also be used for flexible PCBs.

The processing conditions for drilling holes, milling cover films and reinforcing plate shapes are basically the same, but because the adhesive used in flexible PCB materials is soft, it is easy to adhere to the drill bit, and the drill bit status needs to be checked frequently. Increase the drilling machine speed appropriately. Be especially careful when drilling multi-layer flexible PCB circuit boards or multi-layer rigid-flexible PCB circuit boards.

FPC punching

Punching micro holes is not a new technology and has been used in mass production. Due to the continuous production of tape and tape processes, there are also many examples of using punching to process tape and tape through holes. However, batch punching technology is limited to punching holes with a diameter of 0.6-0.8mm. Compared with CNC drilling machine drilling, the processing cycle is long and manual operation is required. Due to the large size of the initial process, the punching die is also correspondingly large, so the price of the die is very expensive. Although mass production is conducive to reducing costs, the equipment depreciation burden is large, and small-batch production and flexibility cannot be compared with CNC drilling, so it is still unpopular.

In recent years, punching technology has made great progress in both die accuracy and CNC drilling, and the practical application of punching on flexible PCBs is very feasible. The latest die manufacturing technology can make holes with a diameter of 75um on non-adhesive copper-clad boards with a substrate thickness of 25um, and the punching reliability is also quite high. If the punching conditions are suitable, even parts with a diameter of 50um can be punched. The hole punching device also uses CNC, and the die can be miniaturized, so it can be well applied to the punching of flexible PCBs. Neither CNC drilling nor punching can be used for blind hole processing.

FPC laser drilling

Lasers can be used to drill the finest through holes. Laser drills used for drilling holes on flexible PCBs include excimer laser drills, impact CO2 laser drills, YAG (yttrium aluminum garnet) laser drills, and argon. laser drills, etc.

The impact CO2 laser drill can only drill the insulating layer of the substrate, while the YAG laser drill can drill the insulating layer and copper foil of the substrate. The speed of drilling the insulating layer is significantly higher than that of drilling the copper foil. Due to the high speed, it is impossible to use the same laser drilling machine to improve the production efficiency of all drilling holes.

Usually, the copper foil is etched first, the hole pattern is formed first, and then the insulating layer is removed to form a through hole so that the laser can drill a hole with an extremely small diameter. However, at this time, the position accuracy of the upper and lower holes may limit the aperture of the drilled hole. If a blind hole is drilled, as long as the copper foil on one side is etched away, there is no problem of upper and lower position accuracy. The process is similar to plasma etching and chemical etching described below.

The holes processed by excimer laser are currently the smallest. Excimer laser is ultraviolet light, which directly destroys the structure of the base resin, making the resin molecules discrete, and the heat generated is very small, so the degree of thermal damage around the hole can be limited to a minimum, and the hole wall is smooth and vertical. If the laser beam can be further reduced, holes with a diameter of 10-20um can be processed.

Of course, the larger the thickness to aperture ratio, the more difficult it is to wet copper plating. The problem with drilling with excimer laser technology is that the decomposition of the polymer produces carbon black attached to the hole wall, so some methods must be taken to clean the surface before electroplating to remove the carbon black. However, when laser processing blind holes, there are also certain problems with the uniformity of the laser, which will produce bamboo-like residues.

The biggest difficulty with excimer lasers is that the drilling speed is slow and the processing cost is high. Therefore, it is limited to small hole processing with high precision and high reliability.

Impact CO2 lasers generally use CO2 gas as a laser source and radiate infrared rays. Unlike excimer lasers, excimer lasers burn and decompose resin molecules due to thermal effects. It belongs to thermal decomposition, and the shape of the processed holes is worse than that of excimer lasers. The processable aperture is basically between 70-100um, but the processing speed is significantly faster than that of excimer lasers, and the drilling cost is much lower. Even so, the processing cost is still much higher than the plasma etching method and chemical etching method described below, especially when the number of holes per unit area is large.

It should be noted that when processing blind holes, the laser can only be emitted to the surface of the copper foil, and the organic matter on the surface does not need to be removed at all. In order to stably clean the copper surface, chemical etching or plasma etching should be used as post-processing. Considering the technical possibilities, it is basically not difficult to use the laser drilling process in the tape and reel process, but considering the balance of the process and the proportion of equipment investment, it is not dominant, but the automatic soldering process of the tape chip (TAB, tape automatic soldering) is narrow in width, and the tape and reel process can increase the drilling speed. There are already practical examples in this regard.

FPC board

FPC hole metallization

The hole metallization of flexible PCB is basically the same as the hole metallization of rigid PCB circuit board.

In recent years, there is a direct electroplating process that replaces chemical plating and adopts the technology of forming a carbon conductive layer. The hole metallization of flexible PCB also introduces this technology.

Due to its softness, flexible PCB requires a special fixing fixture. The fixture not only fixes the flexible PCB, but also must be stable in the plating solution, otherwise the copper plating thickness will be uneven, and it will also cause wire breakage during etching. As well as an important cause of bridging. In order to obtain a uniform copper layer, the flexible PCB must be tightened in the fixture, and the position and shape of the electrode must be manipulated.

For hole metallization outsourcing, it is necessary to avoid outsourcing to factories that have no experience in FPC hole formation. Without a dedicated FPCB plating line, hole quality cannot be guaranteed.

Copper foil surface cleaning for FPC

In order to improve the adhesion of the resist mask, the copper foil surface should be cleaned before applying the resist mask. Even this simple process requires special attention for flexible PCBs.

There are generally chemical cleaning processes and mechanical grinding processes. For the manufacture of precision graphics, in most cases, these two cleaning processes are combined for surface treatment. Mechanical grinding uses a brush coating method. If the brush coating material is too hard, the copper foil will be damaged, and if the brush coating material is too soft, the grinding will be insufficient. Nylon brushes are usually used, and the length and hardness of the throwing brush must be carefully studied. Two brush throwing rollers located on the top of the conveyor belt are used. The direction of rotation is opposite to the direction of belt conveying. However, if the pressure of the throwing brush roller is too large at this time, the substrate will be stretched by a large tension, resulting in dimensional changes. One of the important reasons.

If the surface treatment of the copper foil is not clean, the adhesion with the resist mask will be poor, which will reduce the pass rate of the etching process. Since the quality of copper foil boards has recently improved, the surface cleaning process can also be omitted for single-sided circuits. But for precise graphics below 100μm, surface cleaning is an essential process.

Resist coating-double-sided FPC manufacturing process At present, the coating method of resist is divided into the following three methods according to the accuracy and yield of circuit graphics: screen printing method, dry film/photosensitive method, liquid resist etching photosensitive method.

At present, the coating method of resist is divided into the following three methods according to the accuracy and output of circuit graphics: screen printing method, dry film/photosensitive method and liquid resist photosensitive method.

Anti-corrosion ink uses the screen printing method to print the circuit pattern directly on the surface of copper foil. This is the most commonly used technology, suitable for large-scale production and low cost. The accuracy of the formed circuit pattern can reach a line width/spacing of 0.2-0.3 mm, but it is not suitable for more precise patterns. With miniaturization, this method is gradually unable to adapt. Compared with the dry film method described below, it requires the operator to have certain skills, and the operator must undergo years of training, which is a disadvantage.

As long as the dry film method has perfect equipment and conditions, a line width pattern of 70-80μm can be obtained. At present, most precision patterns below 0.3mm can be formed into resist circuit patterns by the dry film method. Using dry film, its thickness is 15-25μm, and if conditions permit, the batch level can produce patterns with a line width of 30-40μm.

When selecting dry film, it must be determined based on the compatibility with the copper foil board and the process, and through experiments. Even if the experimental level has good resolution, it may not have a high pass rate when used in mass production. Flexible PCBs are thin and easy to bend. If a harder dry film is used, it is fragile and has poor follow-up, so cracks or peeling will occur, which will reduce the pass rate of etching.

The dry film is in roll form, and the production equipment and operation are relatively simple. The dry film consists of a three-layer structure of a thin polyester protective film, a photoresist film, and a thicker polyester release film. Before laminating, first peel off the release film (also called diaphragm), then press it on the surface of the copper foil with a hot roller, and then tear off the upper protective film (also called carrier film or cover film) before developing.

Generally speaking, there are guide positioning holes on both sides of the flexible PCB, and the dry film can be slightly narrower than the flexible copper foil board to be coated. The automatic lamination device for rigid PCB circuit boards is not suitable for the lamination of flexible PCBs, and some design changes must be made. Due to the large line speed of dry film lamination compared with other processes, many factories do not use automatic lamination, but manual lamination.

After pasting the dry film, in order to make it stable, it should be placed for 15-20min before exposure.

If the line width of the circuit pattern is less than 30μm and the pattern is formed by dry film, the pass rate will be significantly reduced. In mass production, dry film is usually not used, but liquid photoresist is used. The coating thickness will vary according to the coating conditions. If a liquid photoresist with a thickness of 5 to 15μm is coated on a copper foil with a thickness of 5μm, a line width of less than 10μm can be etched at the laboratory level.

Liquid photoresist must be dried and baked after coating. Since this heat treatment has a great influence on the properties of the resist film, the drying conditions must be strictly controlled.

iPCB has extensive expertise in manufacturing and assembling PCBs, flexible PCBs, and FPC boards. If you need FPC board manufacturing or assembly, please contact our PCB experts and we will be happy to help you.