Based on the Data Cloud Platform of the Chinese Academy of Sciences, the construction of the LTCC dielectric materials database has been launched.The data structure has been optimized for the characteristics of LTCC materials, covering a full range of information on basic composition, structure, sintering, microwave dielectric properties, magnetic properties, etc.The database now includes its own experimental data and literature data, covering LTCC microwave dielectric materials and other materials. At present, the database has collected more than 5,800 pieces of valid data, including its own experimental data and literature data, covering the fields of LTCC microwave dielectric materials and LTCC ferrite materials. The database will be further improved and enriched to become a key node for data sharing in this field, which will play an important role in the development of new materials in the LTCC field.

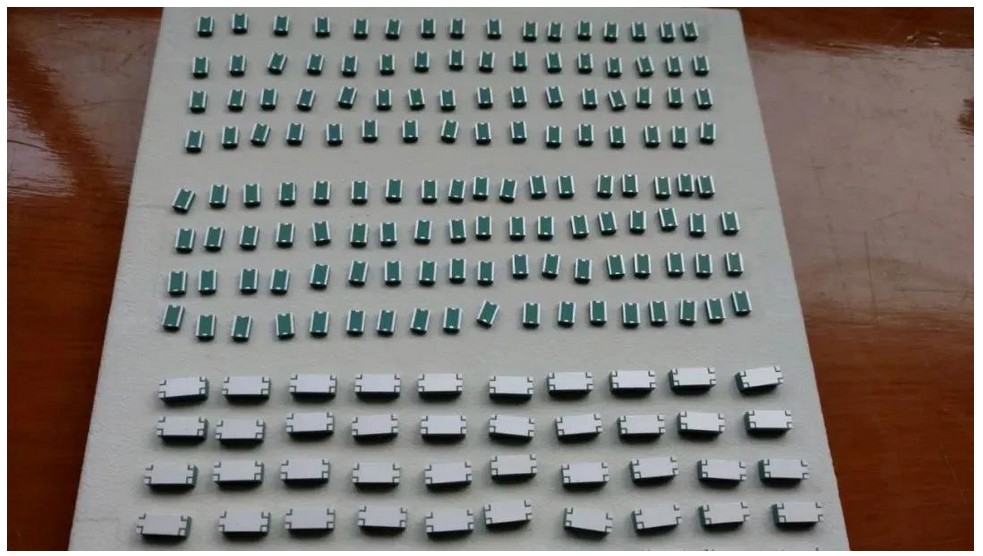

Some of the results of the project have been applied in enterprises,and a number of LTCC filters based on proprietary materials have been successfully developed and realized in small batch production, which plays an important role in updating and upgrading products and enhancing technological competitiveness of enterprises. The research team will focus on promoting the batch stabilization of proprietary LTCC materials and their engineering applications, and at the same time carry out further exploration and research on new high-performance LTCC materials, new passive integration technologies and new applications.

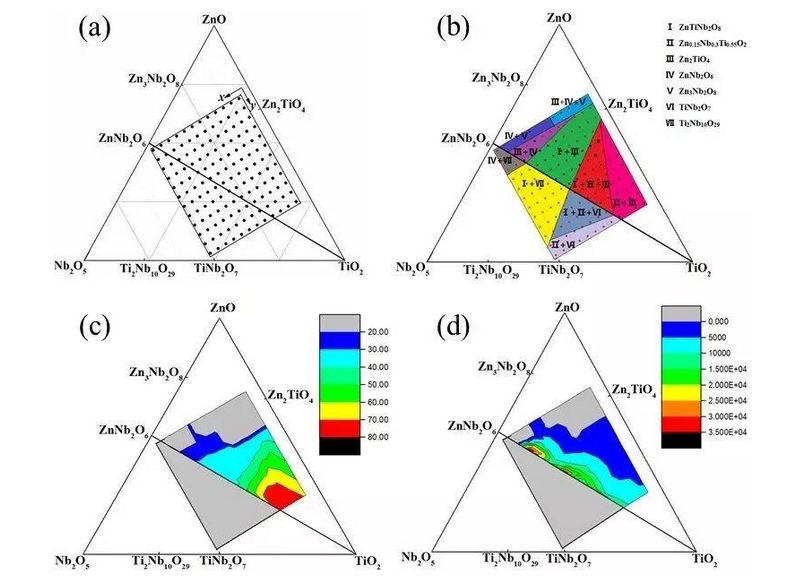

High-throughput experimental study of ceramic materials in the Zn-Nb-Ti-O system: (a) chemical composition of sample arrays; (b) phase partitioning based on high-throughput experiments; (c) dielectric constant mapping; and (d) Q×f value mapping

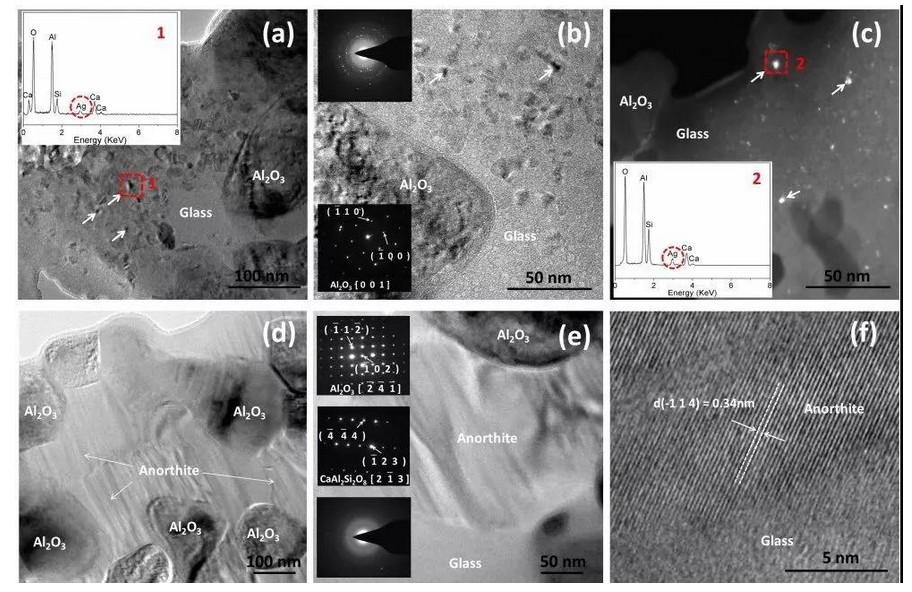

Study of the Diffusion Mechanism of Ag Electrodes in LTCC Materials (J. Am. Ceram. Soc., 99, 2016, 2402)

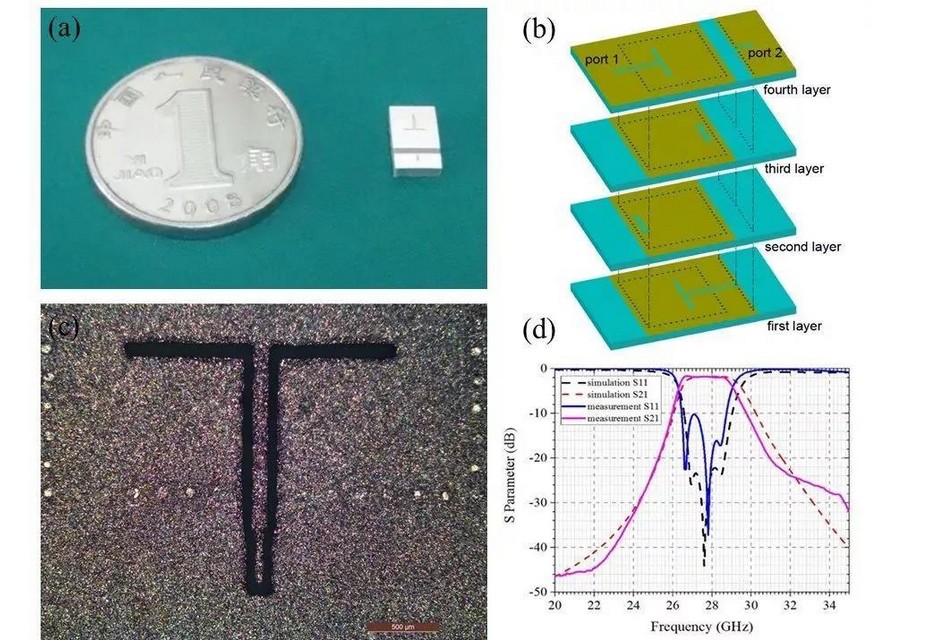

Millimeter-wave filters based on proprietary LTCC materials: (a) physical photo of SIW structured filter; (b) schematic diagram of SIW filter structure; (c) photo of filter test port; (d) comparison of actual results with simulated results

Self-developed LTCC materials are applied in series of filters and couplers.

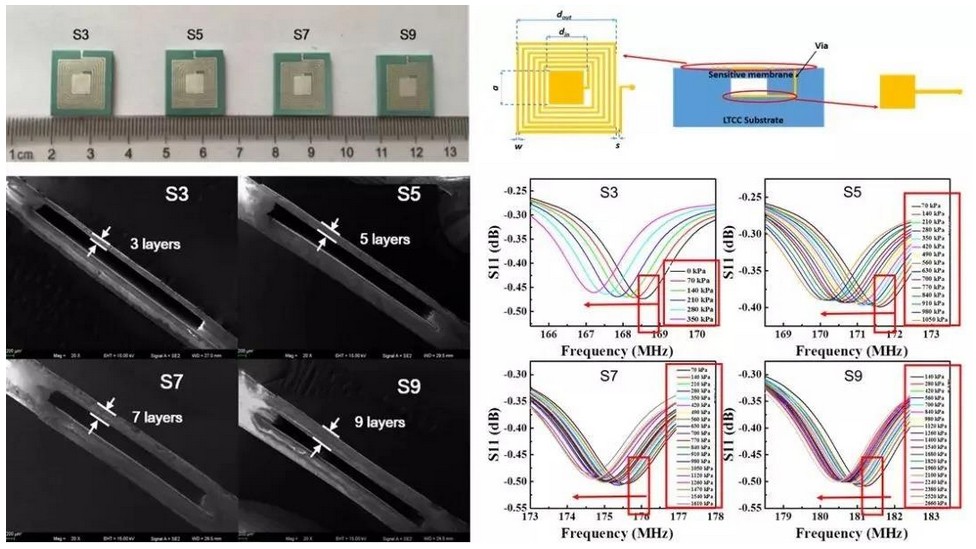

Successful application of proprietary LTCC materials for integrated wireless pressure sensors

<

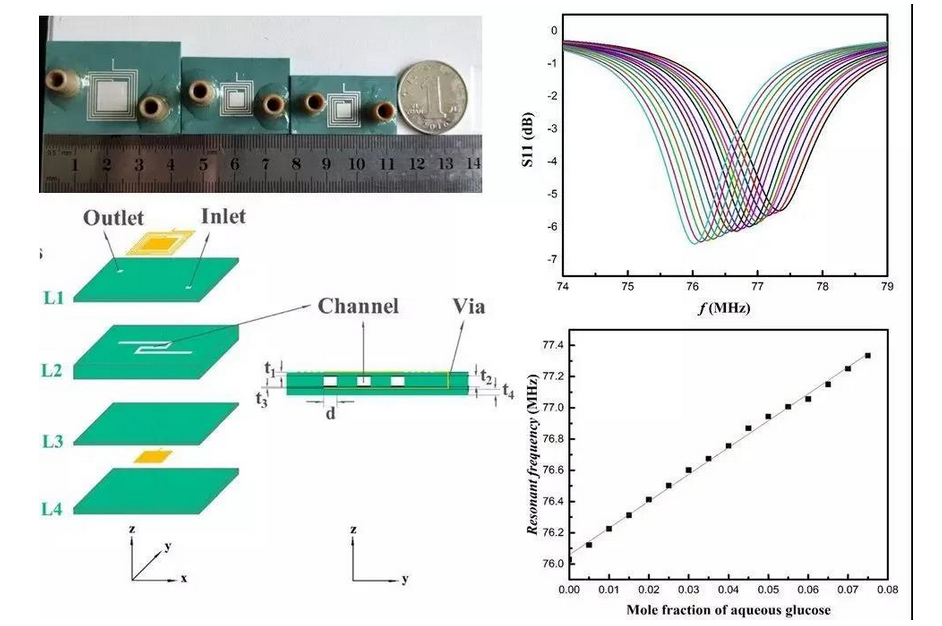

Successful application of proprietary LTCC materials for integrated wireless microfluidic sensors

National High-tech Research and Development Program (“863” program) in the field of new materials technology, “high performance alloys and ceramic materials, cross-scale design and precise control of preparation technology” project acceptance will be held in Beijing, the project successfully passed the acceptance. Among them, by the Chinese Academy of Sciences, Shanghai Institute of Silicate researcher Liu Zhifu responsible for the Shanghai Institute of Silicate and the University of Electronic Science and Technology jointly undertaken the “LTCC materials of high-throughput design, preparation and characterization technology research” project has been organized by the Ministry of Science and Technology on February 8, acceptance of the meeting in Shanghai,the full completion of the various indicators and research objectives, successfully passed the acceptance of the project. The project was established in 2015.

The topic was established in 2015,mainly focusing on the miniaturization,integration,multilayering and high-frequency electronic information systems, high-performance low-temperature cofired ceramics (LTCC) dielectric materials, magnetic dielectric composites application needs,in the establishment of high-throughput experimental techniques and platforms on the basis of the focus on solving the problem of low-temperature sintering and maintaining the contradiction between low loss and low temperature sintering. On the basis of establishing high-throughput experimental technology and platform, we focus on solving the contradiction between low-temperature sintering and maintaining low loss, so as to obtain a series of high-performance and low-loss LTCC mesomaterials and LTCC magneto-magneto-composite materials. Shanghai Institute of Silicate is mainly responsible for the research and development of high throughput experimental technology for LTCC materials and LTCC dielectric materials.

Low Temperature Cofired Ceramics (LTCC) technology has been widely used in radar, aerospace and other special electronic equipment,as well as high-performance computers, wireless communications, automotive electronics and other fields.In particular,5G mobile communication,intelligent network,unmanned driving and other technology leadership, so that modern electronic components and systems are small, thin, light, low power consumption, high reliability as the goal,microwave millimeter-wave materials and integrated devices,integrated systems has become the world's electronics and information field as an important research topic. LTCC technology is the realization of a new generation of passive devices miniaturization, integration, multifunctionality and system-level packaging (SiP). LTCC technology is an important technology path to realize miniaturization, integration, multifunctionalization and system-in-package (SiP) of new generation passive devices. However, the research and development of LTCC materials to device applications is a very complex process, involving ceramic materials, cast paste, component design and manufacturing process and other areas. An LTCC material from R & D to the realization of device applications, from the material formula design, preparation process, powder processing, raw ceramic tape flow extension, device design, device processing technology and performance testing, etc., to determine the optimal material performance, process and final performance of the final product to meet the stereotypes, the research and development difficulties, a long period of time.

Under the support of the “863” project, the passive integrated devices and materials research team of Shanghai Institute of Silicic Acid Technology (SIST) has adhered to the integrated R&D route of LTCC materials-technology-devices, and introduced high-throughput experimental methods into the research and development of LTCC materials, which has improved the efficiency of materials research and development. With the support of the project, we have introduced high-throughput experimental methods into the research and development of LTCC materials, improved the efficiency of material research and development, and made a series of progress in the areas of high-throughput preparation technology for LTCC ceramic materials, high-throughput experimental methods for cast paste, research and development of new LTCC materials and devices, and development of the LTCC material database:

A 16-channel high throughput preparation method and platform for ceramic materials including automatic powder dispensing, automatic mixing, batch molding and batch sintering have been established, and on the basis of fully verifying the validity of the high throughput experimental methods, they have been successfully applied to the composition, physical phase, microstructure and microwave dielectric properties of various systems such as Li-Nb-Ti-O, Zn-Nb-Ti-O and Cu-Nb-Ti-O. “mapping”, which provides an effective way for the screening and performance and process optimization of high-performance LTCC materials (J. Euro. Ceram.Soc.,37, 2017, 3951; Ceram. Int., 43, 2017, 13895); the combination design and high-throughput The idea of combination design and high-throughput parallel processing was introduced to the screening and optimization of ceramic cast paste formulations, based on which a cast paste formulation of ethanol-ethyl acetate mixed solvent system was obtained and successfully used in the preparation of thick film ribbons of several LTCC materials, which proved that the high-throughput method is universal and has important application value for the screening and rapid optimization of the formulation of the cast paste system.

We have developed and optimized the K70 series of high dielectric LTCC microwave dielectric materials,mastered the precise regulation of sintered grains and comprehensive properties,and realized the batch and stable preparation of the materials; and put forward the idea of obtaining ultra-low-loss [tand<0.001@~10 GHz] LTCC dielectric materials through multi-step solid-phase synthesis (ZL 201510109370.3; US9718696; JP2016172683), and developed K5 series millimeter-wave LTCC dielectric materials with dielectric constants of 5~7; directly observed the diffusion path of silver in LTCC materials,and mastered the technological path to inhibit the diffusion of silver electrodes in LTCC materials (J. Am. Ceram. Soc., 99, 2016, 2402).

We are actively expanding the application of self-developed LTCC dielectric materials in multilayer devices. Based on the above self-developed LTCC dielectric materials, we have developed a series of microwave filters, couplers, and duplexers, and developed a high-performance miniaturized LTCC bandpass filter with substrate-integrated waveguide (SIW) structure, which is only one-third of the size of similar filters based on the traditional low-dielectric dielectric materials (Wirel. Commun. Mob. Com., 2018, 9737219, 7). 9737219, 7); advancing the application of LTCC materials in the field of wireless integrated sensors, obtaining highly sensitive LTCC wireless gas sensors that can detect NO2 toxic gases at ppb level (Sensors and Actuators B: Chemical. 239, 2017, 711), as well as LTCC wireless pressure sensors with different pressure detection limits and sensitivities. LTCC wireless pressure sensors with different pressure detection limits and sensitivities.