PCB flying probe test

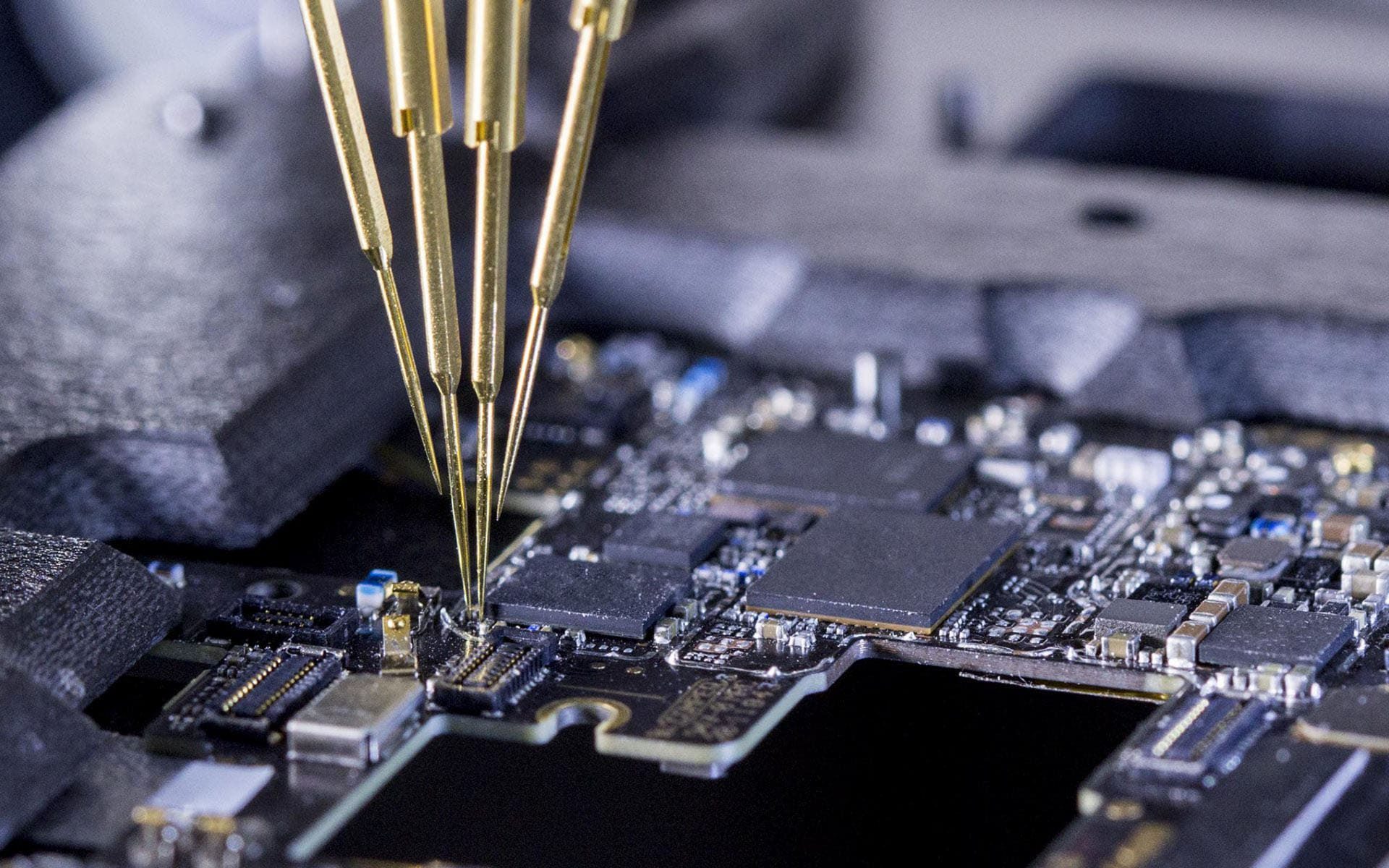

PCB flying probe test is one of the methods used to check the electrical performance of PCB, and it is usually referred to as an open short circuit test. PCB flying probe test with probes to

replace the needle bed, using several motor-driven, fast-moving electrical probes with the device pins for contact and electrical measurements.

Test PCB flying probe tester is for components arranged in high-density, multi-layer, wiring density, small distance between the measurement point of the PCB test a kind of instrument,

the main test circuit board insulation and conduction value.

The tester generally adopts the “true value comparison and localization method”, which can monitor the testing process and fault points in real-time to ensure the accuracy of the test.

Flying probe tester has fine pitch, not limited by the grid, flexible testing, fast speed, and other characteristics.

PCB flying probe test advantages and disadvantages

1. PCB flying probe test can realize high test density, the minimum pitch can be up to 0.05mm or even smaller, which makes it especially suitable for high-density and complex PCB boards.

2. PCB flying probe testing saves time and cost by eliminating the need for specialized test fixtures.

3. PCB flying probe test can quickly complete the test, especially suitable for small batch prototypes and PCB prototyping.

4. The PCB flying probe test is relatively slow because the test is point-by-point contact, especially in the need for large-scale, high-density PCB testing,

the test time may increase significantly.

5. PCB flying probe test needle wear rate is high, long-term use may affect the accuracy of the test.

6. The PCB flying probe test can not test the top and bottom components of double-sided PCB at the same time.

7. The PCB flying probe test is not suitable for mass production, it is mainly more suitable for prototype tests, which may not be economical and efficient enough in mass production.

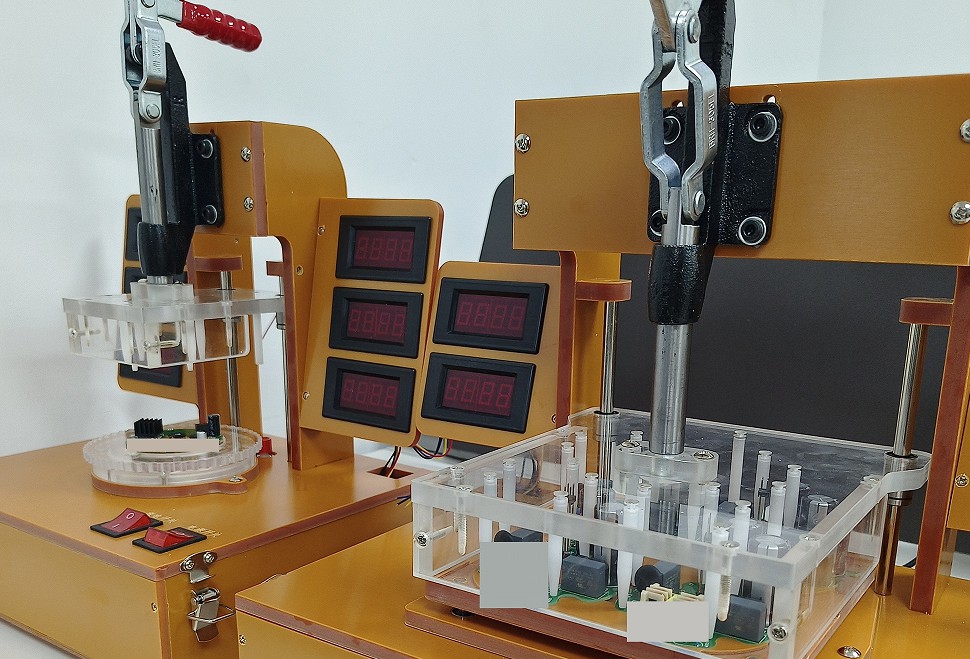

PCB exlusive test fixtures is a specialized equipment for testing PCB boards, the main function is to help manufacturers or users to quickly and effectively test the board after

the completion of the circuit board design, to verify the performance and stability of the PCB. PCB exlusive test fixtures are generally composed of test fixtures and test instruments,

the test fixtures are used to fix the circuit boards, while the test instruments are used to measure the electrical parameters, such as voltage and current.

PCB exlusive test fixtures work by connecting metal probes to the pads or test points on the PCB board, which can obtain the voltage and current values of the test circuits after

power is applied to check the electrical performance of the PCB. PCB exlusive test fixturess are usually used to detect shorts, opens,

and other faults in circuit boards to ensure that PCBs are working properly.

Advantages and disadvantages of PCB exlusive test fixtures

1. In terms of high testing accuracy and cost-effectiveness, it can accurately measure the electrical properties of circuit boards, including connection problems, resistance, and voltage.

2. In terms of batch testing, it can test multiple test points at the same time, which improves testing efficiency.

3. After a one-time investment, there is no additional charge for subsequent return orders, which can save costs for enterprises in the long run.

4. The production of PCB test fixtures requires a high initial investment, and the production process is relatively complex, requiring multiple adjustments and calibration.

5. Not suitable for small quantities or rapid delivery of PCB orders.

6. The flexibility of the PCB test fixture is relatively low,

and the layout of the test points has more stringent requirements and is less suitable for dense arrangements or frequent changes in the design.

PCB flying probe test VS PCB exlusive test fixtures

In practical applications, it is necessary to decide whether to use the PCB exlusive test fixtures according to the specific needs of the PCB.

If the project on the accuracy and stability of the test requires high and can afford the initial investment, the test fixture is undoubtedly an excellent choice.

If the budget is limited or the test demand is not high, it may be more inclined to choose flying probe tests and other more economical testing methods.