When we carry out PCBA board processing, some PCB boards are small in size and need to be split board in order to make them into boards for assembly line for the sake of production efficiency. Then after the completion of the PCBA processing, the need for PCBA board with the board for the sub-panel. Then in the process of sub-panel, need to pay attention to some of the precautions to prevent damage to the intact PCBA board.

PCB design refers to the process of connecting multiple PCBs together through certain pipelines to form an integrated structure.This kind of design pipeline is usually used to solve the problems of insufficient space for single PCB layout, high system complexity, and long distance for signal transmission.By connecting the board design, various functional modules can be distributed on different PCB boards, so as to achieve more efficient and stable system operation.

When manually splitting the board,need to pay attention to folding the edge of the board must be held with both hands on the lower edge of the PCBA board, away from the V-cut up to 20mm or less, as far as possible to avoid bending and deformation,PCBA power circuits and parts,tin road damage.

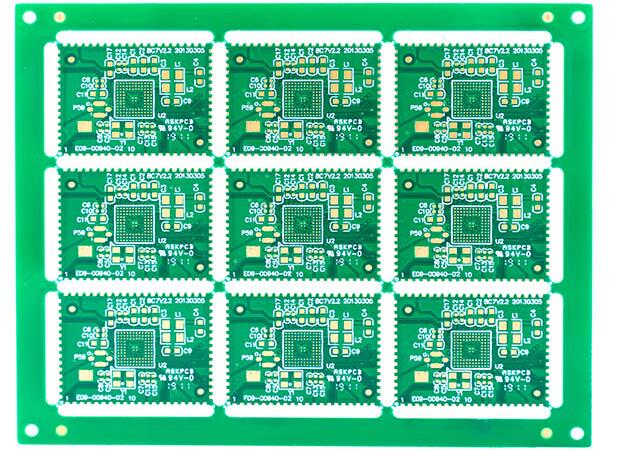

split board

Requirements of machine PCBA sub-panel:

1.Stable support points,no support,the resulting stress may damage the substrate and solder joints. Twisted board, or during the sub-panel to the assembly to generate stress may cause hidden or obvious defects.

2.Wear protective tools,before the operation,must be well prepared for protection, need to add high-frequency eye protection lighting device to protect the safety of the operator. It is best to bring a pair of eyes to protect the safety of the eyes.

3.To use alcohol to frequently wipe the machine spindle and tool to remove the PCBA board dust generated by the process of splitting the board to maintain the normal operation of the splitter.

4.In the operation of a certain number of times, the sliding bar and bearings of the machine and to carry out refuelling smooth, to see if there is no loose screws.

5.In the use of the machine trip, the work table should be insisted on clean, the best not to place other things, to avoid things falling on the tool and the formation of tool damage and damage to the goods. Although there is an electric eye for maintenance, but in the use of travel or pay attention to the fingers and tools to adhere to a certain safety interval.

When PCBA boards are divided into boards, the use of machines to divide the boards than manual division, high efficiency, low damage rate. However, in the machine board, but also in strict accordance with the procedures for the operation, to reduce the human error.