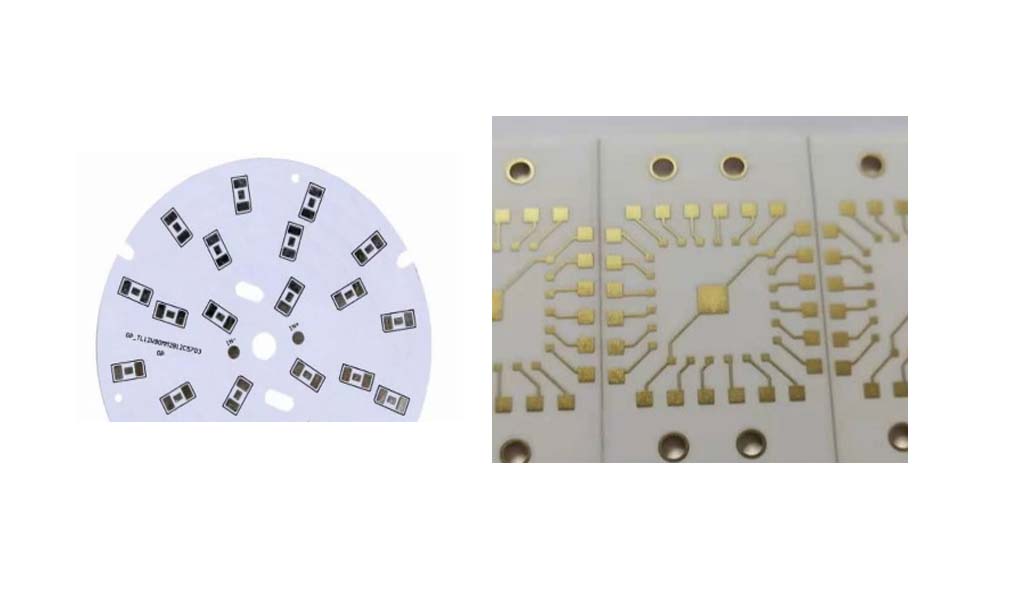

Aluminium pcb circuit board is a metal-based copper-clad board with good heat dissipation function. Generally, a single-sided board consists of three layers, namely the circuit layer (copper foil), the insulating layer and the metal base layer. There are also double-sided boards designed for high-end use, with the structure of circuit layer, insulating layer, aluminium base, insulating layer and circuit layer. Very few applications are multi-layer boards, which can be made by laminating ordinary multi-layer boards with insulating layers and aluminium bases. It is commonly used in LED lighting products. There are two sides, the white side is for welding LED pins, and the other side is the original color of aluminum. Generally, thermal conductive slurry is applied to contact the thermal conductive part. The base material is composed of an aluminum core and standard FR4. It has a thermal insulation layer, which can dissipate heat efficiently, while cooling components and improving the overall performance of the product. At present, many LED lamps and heat dissipation product industries are using aluminium pcb circuit board.

Compared with traditional FR-4, aluminum substrate can reduce thermal resistance to a minimum, making it have excellent thermal conductivity; compared with thick film ceramic circuits, its mechanical properties are extremely good. In addition, aluminum pcb circuit boardhas the following unique advantages:

The heat diffusion is handled extremely effectively in the circuit design scheme, thereby reducing the module operating temperature, extending the service life, and improving power density and reliability;

Reduce the assembly of heat sinks and other hardware (including thermal interface materials), reduce product volume, and reduce hardware and assembly costs; optimize the combination of power circuits and control circuits;

Aluminum is non-toxic and recyclable. Because aluminum is easy to assemble, it also helps save energy. For printed circuit board suppliers, using this metal helps maintain the health of the earth;

Aluminum has incredible durability and is a surprisingly lightweight metal. Aluminum increases strength and elasticity without adding any extra weight.

Layer structure of aluminum pcb circuit board:

1. Circuit layer: The circuit layer (generally electrolytic copper foil) is etched to form a printed circuit for the assembly and connection of devices. Compared with traditional FR-4, with the same thickness and the same line width, aluminum substrate can carry higher current.

2. Insulation layer: The insulation layer is the core technology of aluminum substrate, which mainly plays the role of bonding, insulation and heat conduction. The insulation layer of aluminum substrate is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulation layer, the more conducive it is to the diffusion of heat generated when the device is running, and the more conducive it is to reduce the operating temperature of the device, thereby achieving the purpose of increasing the power load of the module, reducing the volume, extending the life, and increasing the power output.

3. Metal base: What kind of metal is used for the insulated metal substrate depends on the comprehensive consideration of the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of the metal substrate.

In addition to LED, aluminum pcb circuit board also has the following typical application ranges:

1. Power module: Aluminum PCB can withstand high power density and has excellent heat dissipation performance, so it is suitable for various types of power modules.

2. Automotive industry: In the automotive industry, aluminum PCBs are widely used in automotive electronic equipment, automotive lamps and other applications that require high temperature resistance and good heat dissipation performance.

3. Communication equipment: In wireless communication equipment, radio frequency amplifiers and other high-frequency and high-power equipment, it is widely used due to its excellent heat dissipation and radiation suppression characteristics.

4. Solar controller: Solar controllers require a large amount of processing power and generate a certain amount of waste heat, which are consistent with the characteristics of aluminum PCBs.

In short, aluminum PCB circuit board is often an ideal choice when high temperature resistance, excellent heat dissipation or light weight is required but the auxiliary components need to be under heavy pressure.