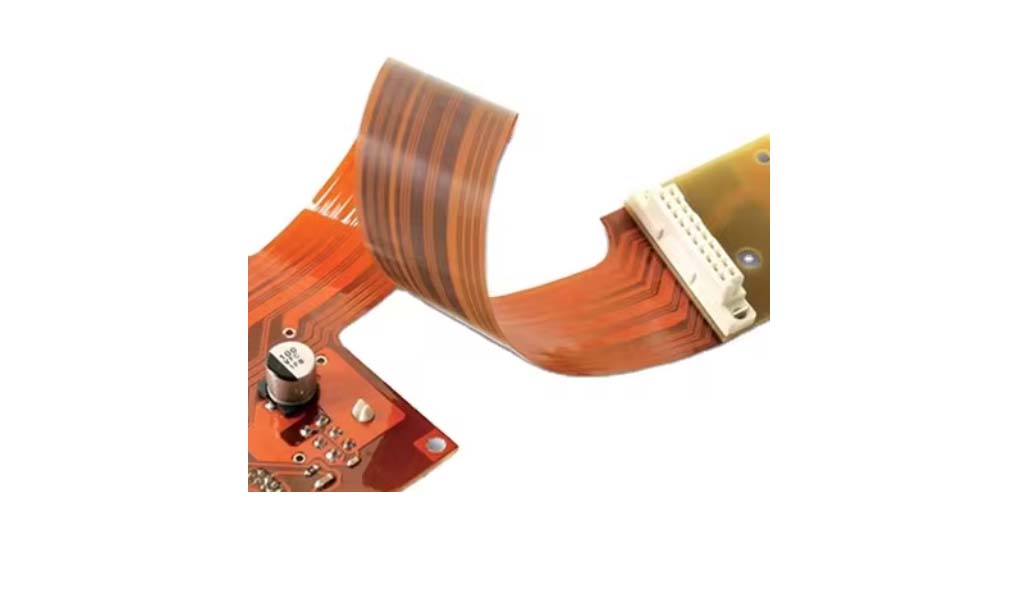

Flexible circuit boards can generally be divided into single-layer flex pcb, double-layer flex pcb, multilayer flex pcb and soft-hard combination pcb. Multi-layer flexible circuit boards are three or more layers of single-sided flex pcb or double-sided flex pcb laminated together, metallized holes are formed by drilling and electroplating, and conductive paths are formed between different layers. In this way, no complicated welding process is required. Although the number of conductive layers designed for this flexible type can be unlimited, in order to ensure convenient assembly, the interaction between assembly size, number of layers and flexibility should be considered in the layout design of multilayer flex pcb.

Advantages:

High assembly density, small size, and light weight. Because of high-density assembly, the connection between components (including parts) is reduced, thereby increasing reliability; it can increase the wiring layer and then increase the design flexibility; it can also constitute the impedance of the circuit, and can form a circuit with a certain high-speed transmission. The circuit and electromagnetic shielding layer can be set, and the metal core layer can also be installed to meet special functions and requirements such as thermal insulation; easy installation and high reliability.

Disadvantages:

High price. The production cost of flexible PCBs is higher than that of rigid PCBs, so the price will be relatively expensive. High environmental requirements. Multilayer flex pcb production requires a high-temperature processing environment, so the requirements for the production environment are also more stringent.

In general, multilayer flex pcbs have good flexibility and reliability, high precision and stability, excellent design freedom and performance, but their prices are relatively high and they have high environmental requirements. Therefore, in practical applications, it is necessary to comprehensively consider their advantages and disadvantages and select suitable materials according to specific needs.

Application scope of multi-layer flexible boards:

1.Consumer electronics field:

Multilayer flex pcb have important applications in the consumer electronics field. For example, in electronic devices such as smartphones, tablets and laptops, as well as wearable devices such as watches and bracelets, multi-layer flexible boards are used as flexible connection lines to connect various components and transmit signals. Its flexibility and bendability enable it to adapt to the design requirements of devices of different shapes and sizes, providing a better user experience.

2.Automotive electronics:

For automobiles, whether they are fuel vehicles or smart vehicles, there are a large number of multilayer flex pcbs, mainly in the automotive electronics sector. Automotive electronics is the general term for automotive electronic control devices and automotive electronic control devices. It mainly includes engine control systems, chassis control systems and automotive electronic control systems; and from the perspective of structure, space, etc., new energy vehicles in the future will definitely use FPC to replace wiring harnesses in large quantities, and will be applied in multiple parts of the vehicle. Therefore, multi-layer flexible board technology is a very important trend in automotive electronics, especially smart cars, especially in battery BMS, vehicle lighting systems, door control systems, camera modules, etc.

3.Industrial control:

Multi-layer flexible boards have a long life and are resistant to aging. They can provide high-performance industrial control systems and are often used in industrial robots, sensors, controllers, etc.

4.Medical equipment:

Multilayer flex pcbs are also widely used in medical equipment, such as medical instruments and some life monitoring equipment, such as endoscopes, facial instruments, and MRI scanning helmets.

In general, multilayer flex pcbs have the advantages of high density, high reliability, high flexibility, light and thin, good solderability, and good bendability. The application range of multilayer flex pcbs is very wide, covering almost all fields that require flexible circuit connections.