Ceramic PCBs are generally made of ceramic materials such as alumina and aluminum nitride, which have superior electrical insulation, thermal management, and mechanical strength, and can maintain high reliability and performance stability at extreme temperatures. Ceramic PCBs usually use high-purity alumina as the base material and can withstand temperatures up to 1000°C, while ordinary PCBs can only withstand temperatures between 100-200°C.

Production principle of ceramic PCB

The copper foil is bonded directly to the ceramic substrate at high temperatures so that the copper foil does not come off easily. This way the ceramic PCB has a strong bonding force, which improves the overall reliability.

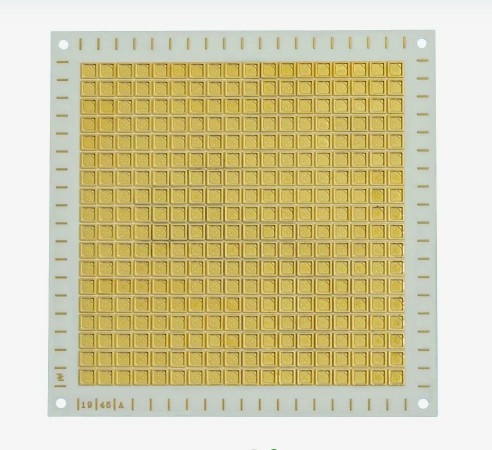

ceramic PCB

Types of Ceramic PCB

Depending on the method of fabrication, ceramic PCBs can be categorized into:

1. HTCC PCB - High Temperature Ceramic PCBs

2. LTCC PCB - Low-Temperature Co-fired Ceramic PCBs

3. Heavy film ceramic PCB

According to the different materials, ceramic PCB can be divided into:

1. Alumina ceramic PCB - Al2O3 PCB

2. Aluminum nitride ceramic PCB - AIN PCB

Ceramic PCBs are widely used in electronic products that require high temperatures, high frequencies, and high currents, such as wireless communications, radar systems, automotive electronics, and advanced medical devices. The reason is that ceramic PCBs have higher thermal conductivity and smaller coefficient of thermal expansion (CTE) than traditional organic material substrates such as FR-4 PCB Board.

These characteristics make ceramic PCBs the preferred choice for coating or encapsulation materials in many electronics industries, such as aerospace, military, and medical devices. In addition, ceramic PCBs are highly corrosion-resistant and can operate stably in environments with strong acids and bases. Based on the current production technology development, although ceramic PCB has excellent performance, its production cost is prohibitive.