Some PCB prototype manufacturers in the publicity of their products, will specifically mention their products using gold-plated, silver-plated and other special processes. So what is the use of this process?

The surface of the PCB prototype needs to be soldered to the components, so a portion of the copper layer needs to be exposed for soldering. These exposed copper layers are called solder pads. Solder pads are generally rectangular or circular in shape and are small in size. We know that the copper used in PCB prototypes oxidises easily, so after the soldermask is applied, the copper on the pads is exposed to the air.

If the copper on the pads is oxidised, not only will it be difficult to solder, but the resistivity will increase dramatically, seriously affecting the performance of the final product. Therefore, engineers have come up with various ways to protect the pads. For example, an inert metal is plated, a layer of silver is applied to the surface by a chemical process, or a special chemical film is applied to the copper layer to prevent the pads from coming into contact with air.

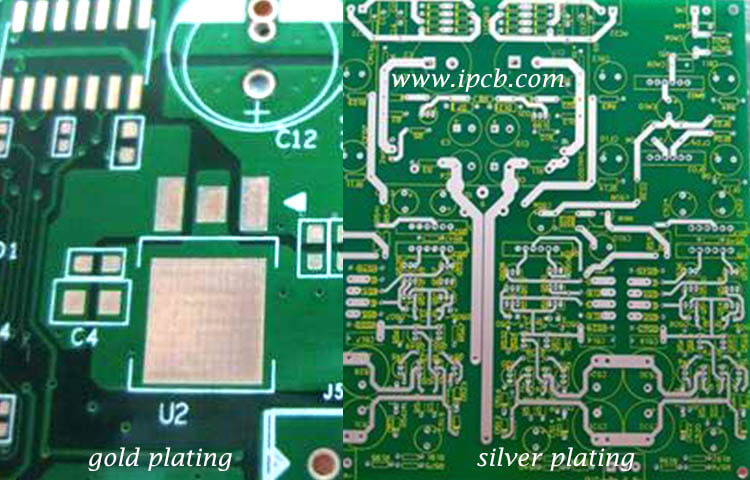

For the exposed pads on the PCB prototype, the copper layer is exposed directly.This part needs to be protected to prevent it from oxidation. From this point of view, the purpose of the process itself, whether gold or silver, is to prevent oxidation and to protect the pads so that yields can be guaranteed in the subsequent soldering process.

Gold and silver plating for PCB prototypes

However, the use of different metals places demands on the storage time and conditions of the PCB prototypes used in the production plant.Therefore,PCB prototype factories usually use vacuum blister packaging machines to package PCB prototypes before they are produced and delivered to customers to ensure that they are not damaged by oxidation.

Before the components are mounted on the machine the board manufacturer must also check the degree of oxidation of the PCB prototypeto eliminate oxidisation of the PCB prototype and ensure the yield rate. The final consumer received the board after a variety of tests, even if the use of a long time,oxidation will almost only occur in the plug-in connection parts,the pad and has been soldered components have no effect.

Since silver and gold have lower resistance will the use of special metals such as silver and gold reduce the amount of heat generated when the PCB prototype is used?

As we know,the factor that affects the amount of heat generated is resistance.Resistance is related to the material of the conductor itself,the cross-sectional area and the length of the conductor.The thickness of the metal material on the surface of the pad is even much less than 0.01 mm.If the pads are processed using the OST (organic protective film) method, there is no extra thickness at all.The resistance of such a small thickness is almost equal to zero and cannot even be calculated, and of course does not affect the heat generation.