Alumina ceramics are now divided into two types: high purity and common type.

High-purity alumina ceramics are ceramic materials with an Al2O3 content of 99.9% or more. Because the sintering temperature is as high as 1650-1990°C and the transmittance wavelength is 1-6 μm, they are generally made into fused glass to replace platinum crucibles: they are used for sodium lamps because of their light transmittance and resistance to alkali corrosion; and they are used as IC substrates and high-frequency insulating materials in the electronics industry. In the electronics industry, it is used as an integrated circuit substrate and high-frequency insulation material.

Common alumina ceramics are divided into 99, 95, 90 and 85 ceramics according to their Al2O3 content, and sometimes those with an Al2O3 content of 80% or 75% are also classified as common alumina ceramics. Among them, 99 alumina ceramic materials are used in high-temperature crucibles, refractory stovepipes and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valves, etc. 95 alumina ceramics are mainly used as corrosion-resistant and wear-resistant parts; 85 ceramics are often doped with part of talc, which improves the electrical performance and mechanical strength, and can be sealed with molybdenum, niobium, tantalum, etc., and used as electro-vacuum device devices.

Alumina Ceramic Powder Preparation

Alumina ceramic powders are prepared according to different product requirements and different moulding techniques. The fineness of the powder is below 1μm micron, and in addition to 99.99% purity of alumina, it needs to be crushed ultra-fine and the particle size is evenly distributed if high purity alumina ceramic products are manufactured. When extrusion moulding or injection moulding is adopted, binder and plasticizer should be introduced into the powder, and generally the organic binder of thermoplastic plastic or resin with a weight ratio of 10-30% should be mixed evenly with the alumina powder at a temperature of 150-200 degrees Celsius, so as to facilitate the moulding operation. For powder materials moulded by hot pressing process, the addition of binder is not required. If semi-automatic or full-automatic dry-pressing moulding is adopted, there are special technological requirements for the powder, and it is necessary to adopt the spray granulation method to treat the powder and make it in the shape of a round sphere, which is conducive to improving the fluidity of the powder so that it can fill up the mould wall automatically in the moulding process. In addition, in order to reduce the friction between the powder and the mould wall, it is also necessary to add 1-2% of lubricant such as stearic acid and adhesive PVA.

For dry compression moulding, it is necessary to spray granulation of the powder, in which polyvinyl alcohol is introduced as a binder. In recent years, a research institute in Shanghai has developed a water-soluble paraffin wax as a binder for spray granulation of Al2O3, which has good fluidity under heating. The powder after spray granulation must have good fluidity, loose density, and the friction temperature of the flow angle is less than 30℃. The particle grade ratio is ideal in order to obtain a greater density of billet.

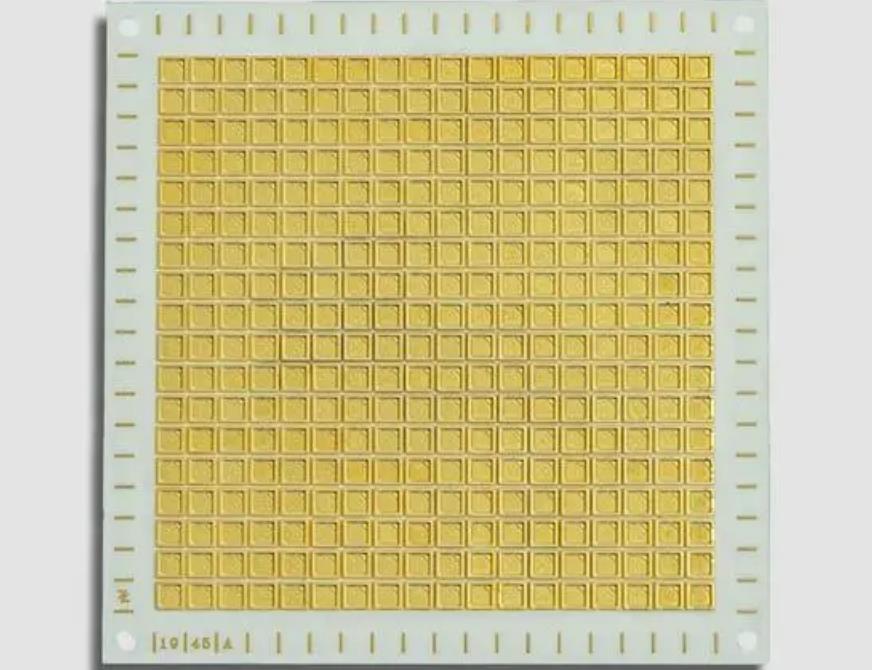

Aluminium oxide ceramic circuit boards

Aluminium oxide ceramics forming methods

Alumina ceramic products can be formed by dry pressing, grouting, extrusion, cold isostatic pressing, injection, casting, hot pressing and hot isostatic pressing. In recent years, the domestic and foreign countries have also developed such moulding technology methods as filtration moulding, direct solidification injection moulding, gel injection moulding, centrifugal injection moulding and solid free moulding. Different product shapes, sizes, complex shapes and precision products require different moulding methods.

Alumina ceramics commonly used forming introduction

1.Dry Pressure Forming: Alumina ceramic dry pressure forming technology is only limited to the objects with simple shape and inner wall thickness more than 1mm, and the ratio of length to diameter is not more than 4:1. There are single-axis or double-axis moulding methods. There are two types of presses: hydraulic and mechanical, which can be semi-automatic or fully automatic.The maximum pressure of the press is 200Mpa, and the production capacity is 15-50 pieces per minute. Since the stroke pressure of the hydraulic press is uniform, the height of the pressed parts is different when there is a difference in the powder filling. Mechanical presses exert pressure that varies according to the amount of powder filling, which may lead to differences in size shrinkage after sintering and affect product quality. Therefore, the uniform distribution of powder particles during the dry pressing process is very important for mould filling. Whether the filling amount is accurate or not has a great influence on the control of the dimensional accuracy of the manufactured alumina ceramic parts. Powder particles larger than 60μm, between 60 ~ 200 mesh can get the maximum free flow effect, to achieve the best pressure moulding effect.

2.Slurry forming method: Slurry forming is the earliest forming method for alumina ceramics. Since plaster mould is used, the cost is low and it is easy to form large-size and complex parts. The key to slurry forming is the preparation of alumina slurry. Usually, water is used as the melting medium, and then the solvent and binder are added, fully milled and ventilated, and then poured into the plaster mould. Due to the adsorption of water by the capillaries of the gypsum mould, the paste is cured in the mould. In the case of hollow grouting, it is necessary to pour out the excess paste when the adsorbed paste reaches the required thickness on the mould wall. In order to reduce the amount of shrinkage of the blank, a high concentration of slurry should be used as much as possible.

It is also necessary to add organic additives to the alumina ceramic slurry to make the surface of the slurry particles form a bi-electric layer so that the slurry is stable in suspension and does not precipitate. In addition, it is also necessary to add vinyl alcohol, methyl cellulose, alginate amine and other binder and polypropylene amine, arabic resin and other dispersants, all in order to make the slurry suitable for injection moulding operation.

3.Alumina ceramic firing technology

The technological method of densifying granular ceramic blanks to form a solid material is called sintering. Sintering is the process of removing the voids between the particles in the body, removing small amounts of gases and impurities, and allowing the particles to grow and combine with each other to form a new material.

The most widely used heating device for sintering is the electric furnace. In addition to atmospheric pressure sintering, i.e. pressureless sintering, there are also hot pressure sintering and hot isostatic pressure sintering. Although continuous hot press sintering increases production, the equipment and mould costs are too high, and the length of the product is limited due to axial heating. Hot isostatic sintering uses high-temperature and high-pressure gas as the pressure transfer medium, which has the advantage of uniform heat in all directions and is very suitable for sintering of complex shapes. Due to the homogeneous structure, the material efficiency is 30-50% higher than that of cold press sintering. It is 10-15% higher than general hot press sintering. In this regard, some high value-added alumina ceramic products or special parts required by the defence industry, such as ceramic bearings, mirrors, nuclear fuel and gun barrels, etc., are now sintered with hot isostatic pressure.

In addition, microwave sintering, arc plasma sintering, and self-propagating sintering technologies are also being developed and researched.

4.Alumina ceramics finishing and packaging process

Some alumina ceramic materials require finishing after sintering. For example, products that can be used as artificial bones require a high degree of surface finish, such as mirror-like surface, in order to increase lubricity. Due to the high hardness of alumina ceramic materials, harder abrasive polishing bricks are required for finishing. Such as SiC, B4C or diamond. Usually, coarse to fine abrasives are used for grinding step by step, and the final surface is polished. Generally, Al2O3 micropowder or diamond paste with <1μm micron can be used for grinding and polishing. In addition, laser and ultrasonic grinding and polishing methods can also be used. Some Alumina ceramic parts need to be encapsulated with other materials.