Alumina substrate pcb are a type of ceramic substrate. Due to their excellent thermal conductivity, insulation, and pressure resistance, they have experienced rapid growth in recent years, playing a vital role in many industries and remaining highly popular. Alumina ceramic substrates are primarily composed of aluminum oxide (Al2O3). These substrates offer excellent conductivity, mechanical strength, and high-temperature resistance. Due to their superior performance, alumina ceramic substrates are increasingly widely used in modern society, meeting the needs of both daily use and specialized industries.

Alumina substrate pcb are divided into standard and high-purity grades. Standard alumina ceramic substrates are categorized by Al2O3 content, including 99% ceramic, 95% ceramic, 90% ceramic, and 85% ceramic. Sometimes, Al2O3 content of 80% or 75% is also considered standard alumina ceramic. 99% ceramic alumina is used in high-temperature tongs, refractory furnace tubes, and specialized wear-resistant materials such as ceramic bearings, ceramic seals, and water valve discs. 95% ceramic alumina is primarily used for corrosion- and wear-resistant components. Because 85 ceramics often incorporate talc, their electrical properties and mechanical strength are enhanced. They can be sealed with metals such as molybdenum, niobium, and tantalum, and some are used in vacuum devices.

Alumina substrate pcb have a high thermal conductivity, generally ranging from 30W to 50W. Thinner sheets offer better thermal conductivity, while thicker sheets exhibit slightly lower thermal conductivity. However, their overall thermal conductivity is 100 times or more that of ordinary PCBs. Furthermore, ceramics are inorganic materials with high hardness, high pressure resistance, and a low coefficient of expansion, making them generally resistant to deformation.

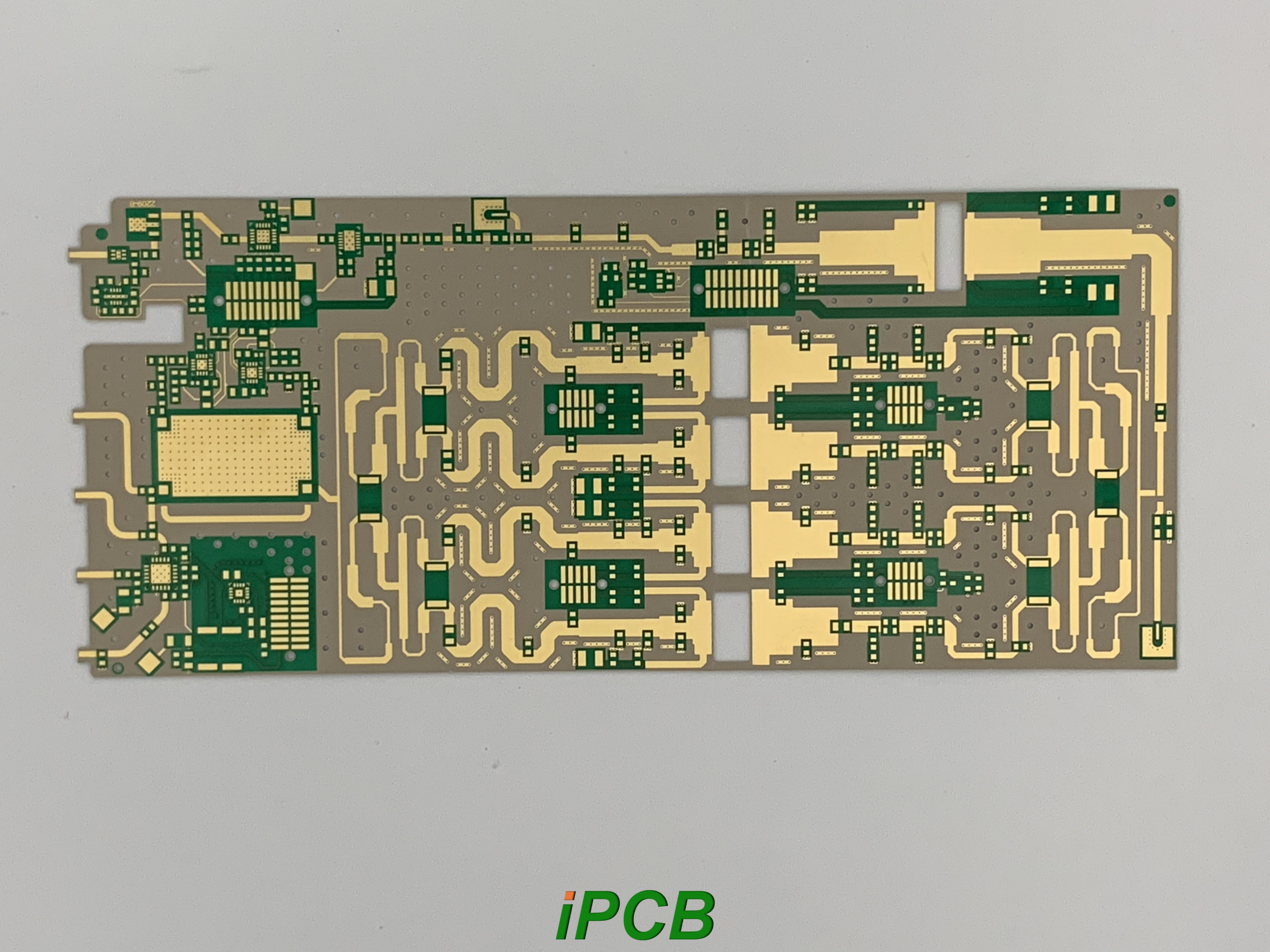

Alumina PCBs are electronic circuit boards fabricated using a specialized process using aluminum as a thermally conductive substrate. These aluminum substrates consist of a circuit layer, a thermally conductive insulating layer, and a metal base layer. The circuit layer (i.e., copper foil) is typically etched to form a printed circuit, interconnecting the various components of the assembly. Generally, the circuit layer requires a high current-carrying capacity, necessitating the use of thicker copper foil, typically 35μm to 280μm. PCB aluminum substrates can be categorized by process, such as tin-sprayed aluminum substrates, oxidation-resistant aluminum substrates, silver-plated aluminum substrates, and gold-immersion aluminum substrates. Based on their application, they can be categorized as streetlight aluminum substrates, fluorescent lamp aluminum substrates, LB aluminum substrates, COB aluminum substrates, package aluminum substrates, bulb aluminum substrates, power supply aluminum substrates, and automotive aluminum substrates.

Applications of alumina substrate pcb in the Electronics Industry:

1. Applications of Multi-Chip Packages: Nano-ceramic alumina ceramic multilayer substrates for packaging can be manufactured using thick film printing, green lamination, and thick film mixing methods. Industrial ceramic alumina substrates are also available.

2. Alumina Ceramic for High-Pressure Sodium Lamp Arc Tubes: Transparent nano-ceramic alumina formed from polycrystalline opaque, high-purity nano-ceramic alumina (VK-L100G, 99.999%) is used in high-pressure sodium lamps. High-efficiency double mercury lamps offer a new approach to improving lighting efficiency. Transparent, high-purity nano-ceramic alumina fine ceramic not only transmits light but also offers high-temperature and corrosion resistance, high insulation, high strength, and low dielectric loss. It is an excellent optical ceramic and can also be used as a microwave oven window.

3. Using alumina ceramic substrates in nanosensors: High-purity nano-alumina ceramics (VK-L100G) utilize structural features such as ceramic particles, grain boundaries, and pores to accurately and rapidly detect and control components sensitive to high temperatures and corrosive gas environments. Depending on the application type, these sensors can be used for temperature, gas, and temperature sensing.

Development Trends in the alumina substrate pcb Industry

1. Technological Innovation and Material Upgrades

The future development of the alumina ceramic substrate PCB industry will depend significantly on technological innovation and material upgrades. As electronic products move toward higher power, higher density, and miniaturization, traditional aluminum substrate materials are unable to meet the growing demands for heat dissipation and electrical performance. Therefore, the PCB aluminum substrate industry will increase research and development of high-performance insulating and thermally conductive materials. For example, the application of nanomaterials is expected to significantly improve the thermal conductivity and mechanical strength of aluminum substrates. Furthermore, the introduction of intelligent manufacturing technologies, such as automated production lines and intelligent detection systems, will significantly improve production efficiency and product quality.

2. Market Demand and Diversified Applications

In the future, the alumina ceramic substrate PCB industry will benefit from continued growth in market demand and diversified applications. With the rapid development of emerging technologies such as 5G communications, new energy vehicles, artificial intelligence, and the Internet of Things, demand for high-performance aluminum PCB substrates will surge. In particular, battery management systems and motor controllers in the new energy vehicle sector urgently require aluminum substrates with high heat dissipation performance. Furthermore, areas such as LED lighting, power modules, and industrial control will continue to drive market growth. To meet the needs of diverse application scenarios, aluminum PCB substrate manufacturers need to develop diversified and customized products and provide one-stop solutions from design to manufacturing.

3. Environmental Protection and Sustainable Development

Environmental protection and sustainable development will become key development directions for the alumina ceramic substrate PCB industry. With increasingly stringent global environmental regulations and growing consumer awareness, aluminum PCB substrate manufacturers must adopt more environmentally friendly production processes and materials. For example, developing halogen-free, low-VOC (volatile organic compound) aluminum substrates can reduce waste and hazardous emissions during the production process.

Furthermore, the circular economy and resource reuse will become key topics in the aluminum PCB substrate industry. Recycling and reusing scrap aluminum substrates not only reduces raw material costs but also minimizes negative environmental impacts. Implementing a sustainable development strategy not only helps aluminum PCB manufacturers enhance their sense of social responsibility but also strengthens their brand image and market competitiveness, laying a solid foundation for the long-term development of the aluminum PCB industry.

Alumina substrate pcb offer significantly better heat dissipation, current carrying capacity, electrical insulation, and thermal expansion coefficient than ordinary fiberglass PCBs. Unlike conventional PCBs, which use adhesives to bond the copper foil to the substrate, ceramic PCBs are produced by directly bonding the copper foil to the ceramic substrate in a high-temperature environment. This strong bond prevents the copper foil from falling off, and provides high reliability and stable performance in high-temperature and high-humidity environments.