Alumina ceramic substrate heaters, i.e. metal ceramic heaters (hereinafter referred to as "MCH") use high temperature co-fired multi-layer ceramic substrate technology. According to the design requirements, the heating resistance paste is printed on the cast ceramic blank. The heating circuit and then the multi-layer combination is fired into a single unit, which has the characteristics of corrosion resistance, high temperature resistance, and long service life. With a long, high efficiency and energy saving, temperature uniformity, good thermal conductivity, fast thermal compensation, does not contain lead, mercury, hexavalent chromium and other hazardous substances, in full compliance with the European Union environmental requirements.

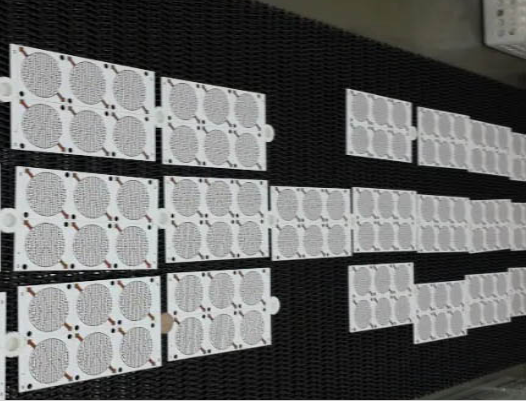

Nowadays, the ceramic substrate manufacturing process of ceramic substrate manufacturers is becoming more and more mature, and most of the demands can be satisfied! If you have a need for ceramic substrates, you can consult Abbey Circuits, we have more than 10 years of circuit board manufacturing experience in the production of alumina ceramic substrates and aluminium nitride ceramic substrates, can be processed for precision circuits, solid copper filled holes, LED inorganic dam process.

Comparison of Aluminium Nitride Ceramic Substrate and Aluminium Oxide Ceramic Substrate

1. Aluminium oxide ceramics (Al2O3)

The main component of aluminium oxide ceramics is Al2O3, with a general content of more than 45%. Aluminium oxide ceramics have various excellent performance. Resistant to high temperature, generally can be 1600 ℃ long-term use, corrosion resistance, high strength, its strength for ordinary ceramics 2 ~ 3 times, the higher can reach 5 ~ 6 times. Its disadvantage is brittle, can not accept sudden changes in ambient temperature. Extremely wide range of uses, can be used as crucibles, engine spark plugs, high temperature refractory materials, thermocouple casing, sealing rings, etc., can also be used as cutting tools and moulds.

2. Aluminium nitride ceramics (Si3N4)

Silicon nitride ceramic main component is Si3N4, which is a high-temperature strength, high hardness, wear-resistant, corrosion-resistant and self-lubricating high-temperature ceramics, line expansion coefficient in a variety of ceramics is the smallest, the use of up to 1400 ℃, has excellent corrosion resistance, in addition to hydrofluoric acid, can be resistant to a variety of other acid corrosion, and can be resistant to alkali, a variety of metal corrosion, and has excellent electrical insulation and radiation resistance. Can be used as high-temperature bearings, sealing rings used in corrosive media, thermocouple casing, can also be used as metal cutting tools.

3. Silicon carbide ceramics (SiC)

Silicon carbide ceramics are mainly composed of SiC, which is a high-strength, high hardness of the high-temperature ceramics, 1200 ℃ ~ 1400 ℃ use can still maintain high bending strength, is the current high-temperature strength of ceramics, silicon carbide ceramics also has a good thermal conductivity, oxidation resistance, electrical conductivity and high impact toughness. Is a good high-temperature structural material, can be used for rocket tail nozzle nozzle, thermocouple casing, furnace tube and other high-temperature parts; use its thermal conductivity can be made at high temperatures under the heat exchange material; use its high hardness and wear resistance to make grinding wheels, abrasives and so on.

4. Hexagonal boron nitride ceramics (BN)

Hexagonal boron nitride ceramics are mainly composed of BN, the crystal structure of the hexagonal crystal system, hexagonal boron nitride structure and performance similar to graphite, so there is a "white graphite" of the name, the hardness is relatively low, can be machined with self-lubricating, can be made into self-lubricating high temperature bearings, glass forming moulds and so on.

1. Hard alloy

Cemented carbide is mainly composed of carbide and binder, carbide is mainly WC, TiC, TaC, NbC, VC, etc.binder is mainly cobalt (Co). Carbide compared with tool steel, high hardness (up to 87 ~ 91HRA), good thermal hardness (about 1000 ℃ excellent wear resistance), used as a cutting tool, cutting speed than high-speed steel to increase 4 ~ 7 times, life increased by 5 ~ 8 times, the disadvantage of its hardness is too high, brittle, it is difficult to be mechanically processed, and therefore often made into blades and welded in the shank of the tool to be used, the carbide is mainly used in machining tools; Various types of moulds, including drawing dies, drawing dies, drawing dies, moulds, moulds, moulds, moulds, moulds, moulds, moulds, moulds, moulds, moulds, moulds and tools Various kinds of moulds, including drawing moulds, pulling moulds and cold moulds; mining tools, geological and petroleum exploitation with various kinds of drills.

2. Diamond natural diamond (diamond)

Diamond natural diamond (diamond) is used as precious ornaments, while synthetic diamond is widely used in industry.Diamond is the hardest material in nature and has extremely high modulus of elasticity; the thermal conductivity of diamond is among the known materials; and the insulating effect of diamond is very good. Diamond can be used as drills, knives, grinders,drawing dies, dressing tools; diamond tools for ultra-precision machining, can achieve mirror finish. However, the thermal stability of diamond tools is poor, and the affinity of the ferrous elements, so it can not be used in the processing of iron, nickel-based alloys,and the main processing of non-ferrous metals and non-metals, widely used in ceramics, glass, stone, concrete, gemstones, agate and other processing.

3. Cubic boron nitride (CBN)

Cubic boron nitride (CBN) has a cubic crystal structure, its high hardness, second only to diamond, its thermal stability and chemical stability than diamond is good, can be used for hardened steel, wear-resistant cast iron, thermal spraying material and nickel and other difficult-to-machine materials such as machining. It can be made into cutting tools, grinding tools, wire drawing moulds and so on.Other tool ceramics other tool ceramics such as aluminium oxide, zirconium oxide, silicon nitride ceramics, but from the comprehensive performance and engineering applications are not as good as the above three kinds of tool ceramics.

Advanced ceramic materials are integral to various high-tech fields such as communications, electronics, aviation, aerospace, and the military. In the electronics sector, they're known as electronic ceramic materials and serve multiple functions including insulation, substrate, packaging, and as components in electronic devices like capacitors, piezoelectric ceramics, and ferrite magnetic materials. Piezoelectric, ferroelectric, and magnetic ceramics are essential for electronic technology and large-scale integrated circuits. Ferromagnetic ceramics with square magnetic hysteresis lines are crucial for computer memory systems, while ceramic bearings are necessary for high-speed hard disk rotating systems. In aerospace applications, ceramics are vital for components like nose cones and wave-transparent ceramic antenna covers, providing high-temperature strength and oxidation resistance. Ceramics also play roles in emerging technologies like magnetorheological generators, high-temperature fuel cells, and high-energy batteries, serving as electrode and diaphragm materials for ionic conductors.