Due to its excellent thermal conductivity and electrical insulation properties, aluminum nitride (AlN) ceramic has become an ideal material for the next generation of heat dissipation substrates and electronic device packaging. It has been widely applied in various civilian and military fields. With the advent of 5G, new energy vehicles, and artificial intelligence, an integrated upstream and downstream layout has become a rational choice for aluminum nitride ceramic substrate companies to enhance their competitiveness.

1. Advantages of Aluminum Nitride Ceramic Substrates

High Thermal Conductivity

AlN ceramic substrates have a high thermal conductivity, ranging from 170 to 230 W/m·K, which aids in heat dissipation, effectively reducing thermal resistance and improving thermal performance.

Corrosion Resistance

AlN ceramic substrates possess excellent corrosion resistance, making them suitable for use in acidic, alkaline, and high-pressure environments.

Low Coefficient of Thermal Expansion

AlN ceramic substrates have a very low coefficient of thermal expansion, which ensures good dimensional stability at high temperatures, reducing the risk of deformation.

Strong Bonding Force

The strong bonding between the metal layer and the ceramic in AlN substrates provides significant application advantages due to the high bonding strength between these layers.

Good High-Frequency Performance

AlN ceramic substrates have low high-frequency loss and a small dielectric constant, making them suitable for high-frequency circuit design and assembly. They also support high-density assembly, with line/space (L/S) resolutions reaching 20μm, which is ideal for compact, lightweight devices in today’s tech trends.

Wide Application Range

Thanks to these advantages, AlN ceramic substrates are widely used in aerospace, communication, lighting, and household appliances.

2. Aluminum Nitride Ceramic Substrate Press Molding Process

Raw Material Preparation

The raw materials for AlN ceramic substrates mainly include aluminum nitride powder, binders, plasticizers, solvents, etc. High-purity raw materials are selected to ensure substrate quality and performance. Fine grinding and mixing of the raw materials are required for uniformity and stability.

Mixing and Granulation

Raw materials are mixed in specific proportions to ensure consistency in the substrate's composition and quality. Granulation forms the mixture into specific shapes and sizes, suitable for molding. Proper control of particle size and shape ensures optimal molding quality.

Molding

Granulated raw materials are pressed into the desired shape and size. Control of pressure and temperature is critical to ensure the substrates meet dimensional and quality requirements.

Debinding and Sintering

Debinding removes binders from the molded substrates, providing necessary strength and stability. Sintering involves heating the debound substrates to a high temperature, making them dense and strong. Temperature and time control during sintering are essential for maintaining the desired substrate properties.

Cooling and Processing

The sintered substrates are cooled gradually to avoid cracks and defects. Further processing, such as mechanical machining, grinding, and polishing, improves the appearance and quality.

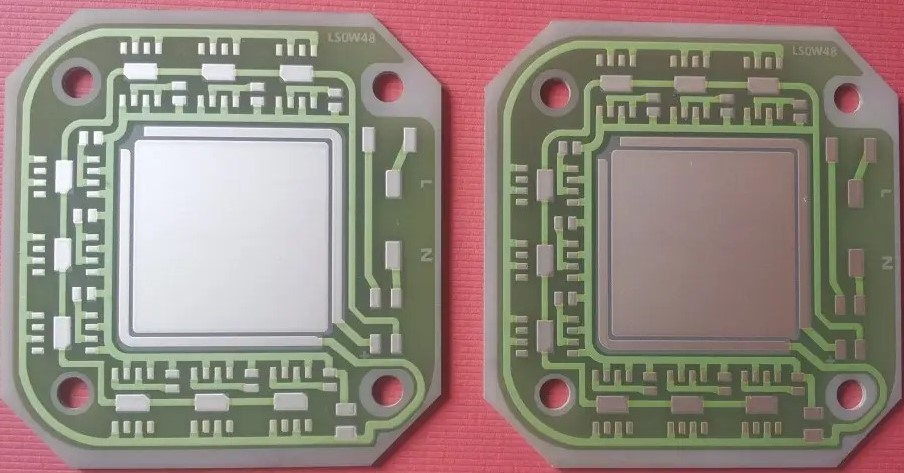

Aluminum Nitride Substrate

3. Aluminum Nitride Ceramic Substrate Tape Casting Process (Waterless)

Formulation and Mixing

During the tape casting process, AlN powder, binders, plasticizers, and solvents are mixed according to a specific formula to ensure product performance and quality.

Plasticizing and Tape Casting

After heating and stirring, the mixture is transformed into a plasticized slurry, which is evenly cast onto preheated rolls to form a thin film. Proper control of temperature, pressure, and flow ensures uniformity and smoothness of the film.

Heat Treatment and Sintering

After tape casting, heat treatment and sintering strengthen the film and enhance its stability. Precise temperature and time control ensures high-quality ceramic substrates.

Cooling and Processing

After sintering, the AlN ceramic substrates are cooled and further processed to meet desired specifications, such as thickness, flatness, and appearance.

4. Detection of Aluminum Nitride Substrates

Appearance Inspection

Check for surface flatness, smoothness, and the absence of visible defects like scratches, bubbles, and cracks.

Dimensional Inspection

Measure length, width, and thickness to ensure compliance with required specifications.

Composition Analysis

Use chemical or spectral analysis to check the content of AlN and impurities.

Mechanical Property Testing

Test hardness, flexural strength, and wear resistance to ensure the substrate can withstand mechanical loads.

Electrical Performance Testing

Measure electrical conductivity and resistivity to meet the needs of different electronic products.

Environmental Adaptability Testing

Conduct high-temperature, low-temperature, humidity, and salt spray tests to ensure substrates can function in various environments.

Aluminum nitride, as a new high thermal conductivity ceramic material, has a thermal expansion coefficient close to silicon, excellent heat dissipation performance, and is non-toxic. Therefore, it serves as an excellent alternative to traditional ceramic substrates in the electronics industry, with minimal threat from substitutes in heat dissipation applications.