The aluminum oxide ceramic substrate microstrip filter has been widely used in fields such as communications and electronic warfare. However, its power handling capacity is often limited, affecting the overall system performance. To address this issue, researchers have begun exploring the use of advanced thermal management technologies to enhance the power handling capacity of aluminum oxide ceramic substrate microstrip filters.

Thermal management technology is a technique that controls heat conduction, convection, and radiation to maintain the temperature of electronic devices within a stable and acceptable range, thereby improving their reliability and performance. For aluminum oxide ceramic substrate microstrip filters, the introduction of new thermal management technologies can effectively reduce operating temperatures and improve power handling capacity.

Specifically, the advanced thermal management technology is achieved through the following methods:

1.Enhancing thermal conductivity: By adding a layer of material with high thermal conductivity, such as copper or aluminum, to the surface of the aluminum oxide ceramic substrate microstrip filter, the heat conduction rate can be increased, thus lowering the operating temperature.

2.Thermal convection enhancement: Installing heat sinks or fans on the surface of the aluminum oxide ceramic substrate microstrip filter can promote airflow and accelerate the cooling process.This can be achieved by:

Mounting heat sinks on the back or sides of the filter, which dissipate heat to the external environment through natural or forced convection.

Installing fans or vents on the filter's surface to allow air circulation, carrying heat away from the surface and reducing surface temperature.

3.Thermal radiation enhancement: Coating the surface of the aluminum oxide ceramic substrate microstrip filter with materials that have high emissivity, such as black paint or graphite, can convert heat into radiated energy and release it into the environment.

These methods can be used individually or in combination to significantly enhance the power handling capacity of aluminum oxide ceramic substrate microstrip filters. In practical applications, appropriate methods should be chosen based on specific needs and constraints, with further optimization and improvement as needed.

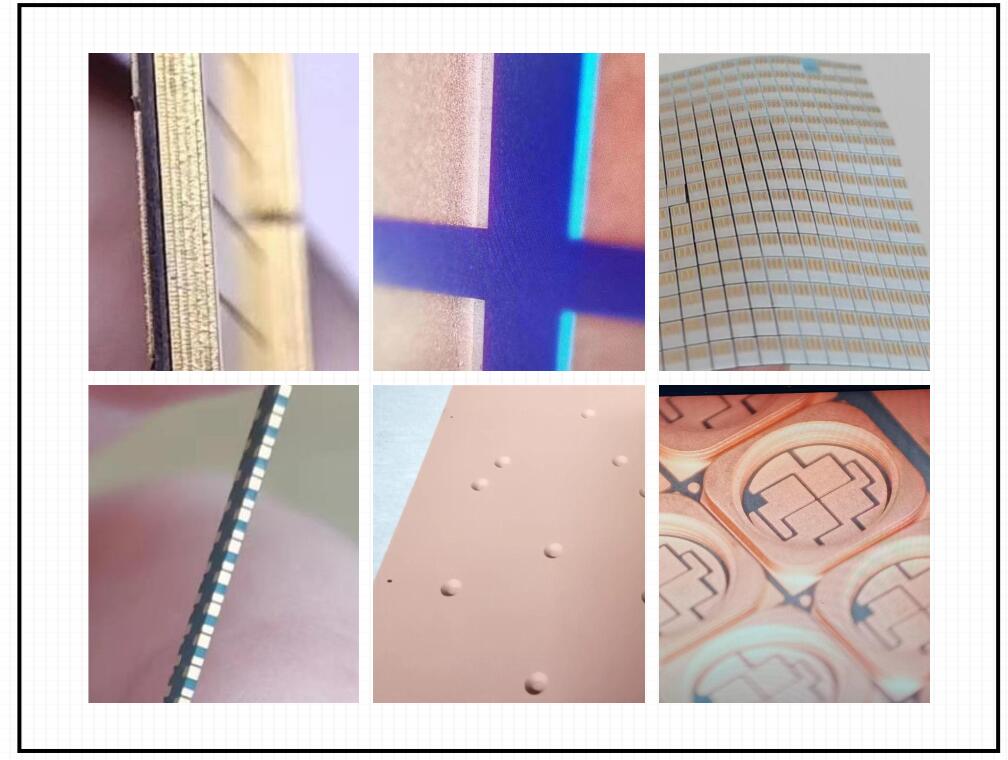

Aluminum oxide ceramic substrate

In addition to the methods mentioned above, advanced thermal management technologies also include other techniques, such as thermocouples, thermistors, and intelligent temperature control technologies based on microprocessors or electronic control units. These technologies can further optimize the power handling capacity of aluminum oxide ceramic substrate microstrip filters by monitoring and controlling system temperatures in real time.

The use of advanced thermal management technology plays a crucial role in improving the power handling capacity of aluminum oxide ceramic substrate microstrip filters. With the continuous development and innovation of related technologies, we can expect more efficient and reliable filter products and applications in fields such as communications, aerospace, and military.

The power handling capacity of aluminum oxide ceramic substrate microstrip filters treated with advanced thermal management technology has significantly improved. Individually, the use of high thermal conductivity materials, heat sinks, or high-emissivity coatings increased power handling capacity by 20%, 15%, and 34%, respectively. When the three methods were combined, the improvement reached as high as 40%.

Advanced thermal management technology has shown significant effects in enhancing the power handling capacity of aluminum oxide ceramic substrate microstrip filters. As the demand for high-performance filters continues to grow in fields like communications and electronic warfare, this technology will have broad application prospects in the future.

With the development of 5G, the Internet of Things, and other technologies, the transmission speed and data volume of communication systems will require higher standards. This will further increase the operating frequency and power requirements of filters, highlighting the importance of advanced thermal management technologies.

As the aerospace and military sectors continue to develop, the demand for high-performance filters will also increase. In these fields, the working environment is often harsh, requiring effective thermal management measures to ensure the stable operation of filters. Therefore, advanced thermal management technologies will also have wide application prospects in these areas.

With continuous advancements in materials science and manufacturing processes, the effectiveness and reliability of advanced thermal management technologies will further improve. This will bring new opportunities and challenges to the development of aluminum oxide ceramic substrate microstrip filters. Future research should focus on optimizing the design of advanced thermal management technologies to improve their practicality and scalability, meeting the needs of various application scenarios.

The use of advanced thermal management technologies to enhance the power handling capacity of aluminum oxide ceramic substrate microstrip filters has shown significant improvement. Aluminum oxide ceramic substrates will provide strong support for the development of fields such as communications, aerospace, and military.