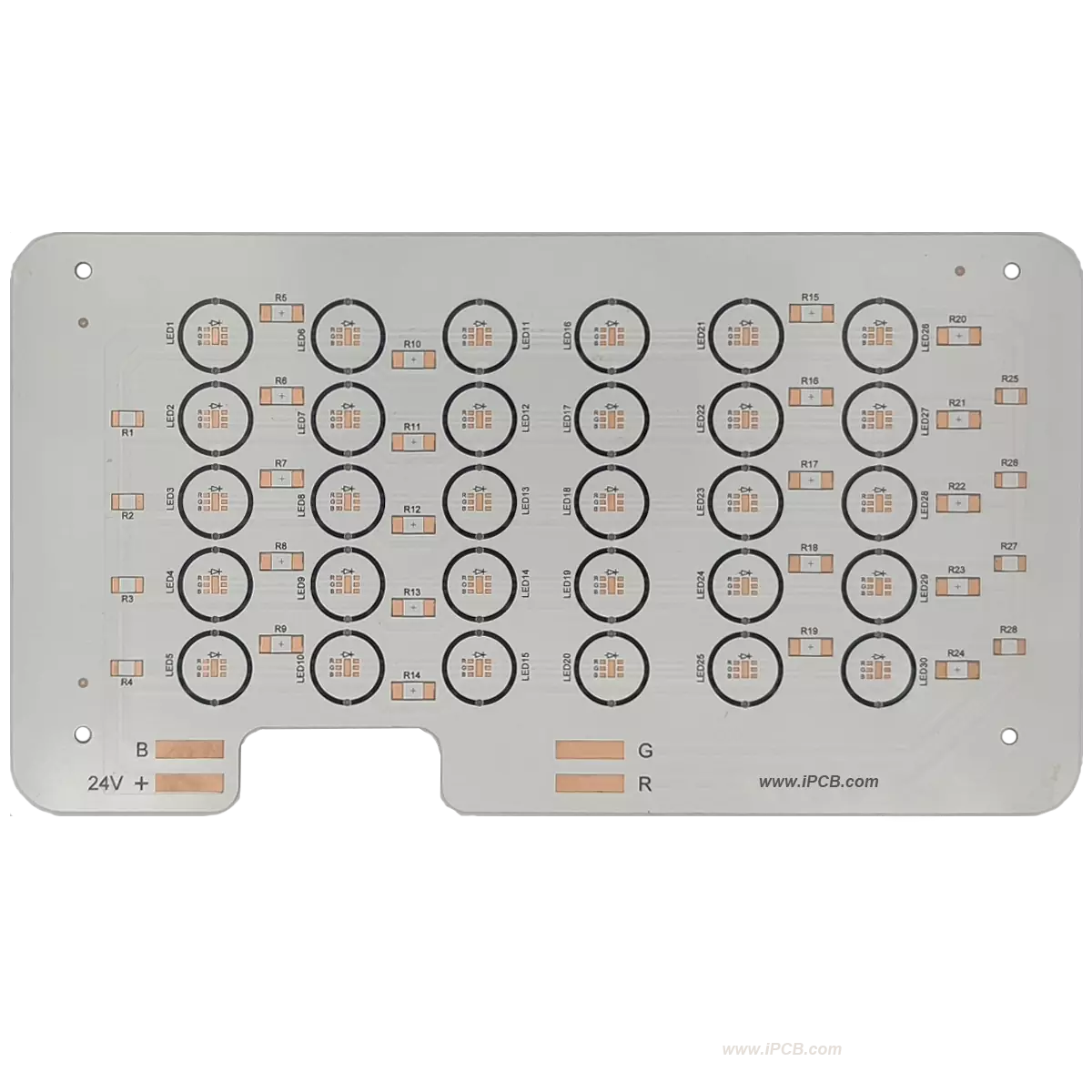

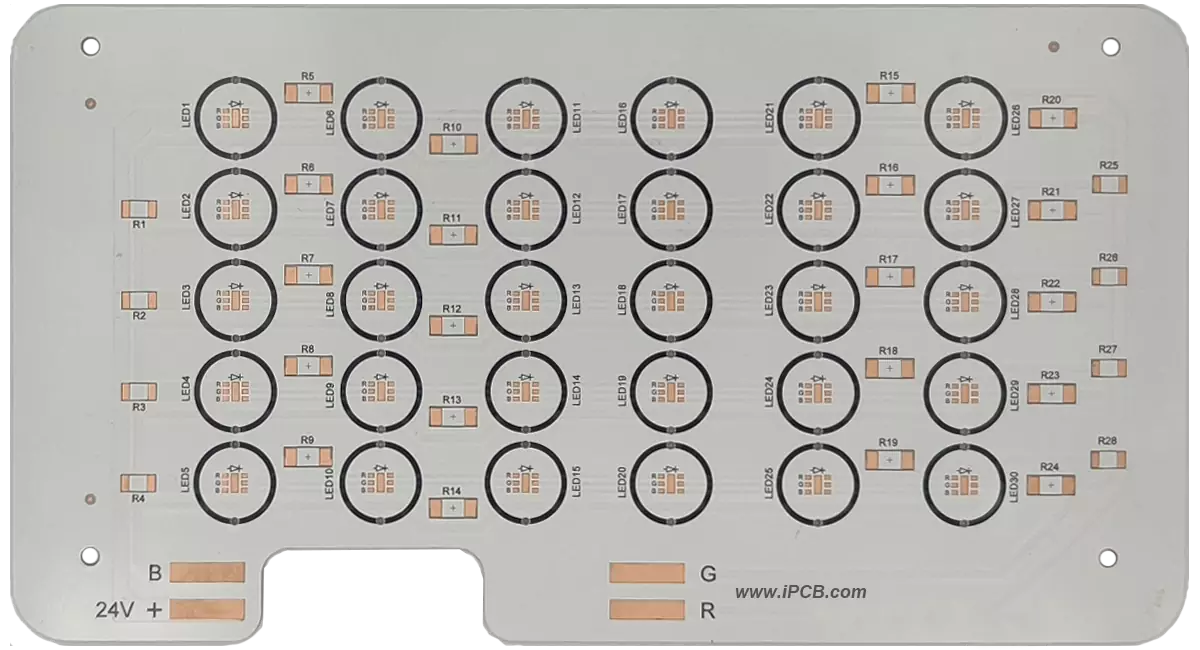

Product: Aluminum PCB

Material: aluminum substrate

Layer: 1

Color: White/Black

Finished thickness: 1.6mm

Copper thickness: 1oz

Surface treatment: OSP

Minimum line width: 8mil

Minimum spacing: 10mil

Thermal conductivity: 1-3W/mK

Application: LED Lamp

Aluminum PCB is a widely used circuit board and also the cheapest among metal circuit boards. Aluminum PCB has good thermal conductivity. Aluminum PCB is the most cost-effective circuit board among boards with heat dissipation performance. Aluminum PCB is divided into three layers: the upper layer is the wiring layer, the middle layer is the thermal conductivity and insulation layer, and the lower layer is the metal aluminum substrate with heat dissipation function.

FR-4 Circuit board dominates in epoxy resin fiberglass board due to its absolute advantage of high flame retardancy. FR-4 Circuit board is composed of high-temperature resistant composite materials and glass fibers, which have the characteristics of high dielectric, heat resistance, and moisture resistance.

Aluminum PCB is the most common type of metal PCB board, which is composed of aluminum cores with standard FR-4. Simply put, it consists of a three-layer structure of copper foil, insulation layer, and metal core. Due to the heat dissipation layer on the aluminum PCB board, it has good heat dissipation function, which can effectively reduce the operating temperature of components and extend the service life of products.

The difference between aluminum PCB and standard FR-4 board

1. The metal layer of aluminum PCB board can quickly dissipate heat, transfer the heat of the device, and minimize the thermal resistance, with good thermal conductivity performance.

2. Aluminum PCB board does not contain harmful substances to human health and the environment, making it more environmentally friendly than FR-4 board.

3. The FR-4 board may experience warping, bending, cracking, and other issues during production and transportation. Ceramic substrates are also more fragile. Aluminum PCB compensates for the shortcomings of FR-4 board and ceramic substrate, providing longer durability and avoiding board cracking during production and transportation.

4. The circuit layer of aluminum PCB board is formed by etching, and compared with traditional FR-4 board, the current carried by aluminum circuit board is higher under the same line width, thickness and other conditions.

5. FR-4 Circuit board varies greatly in price depending on the board, structure, and other aspects. For example, the price difference between single and double-sided panels and multi-layer panels is relatively large. But aluminum PCB board have superior performance, so overall the price of fiberglass boards is higher.

6. The circuit layer of aluminum PCB is only one layer, while fiberglass board can have single-sided, double-sided, and multi-layer circuits connected through vias. The complexity of the two processes varies greatly, and the manufacturing process is also very different.

Aluminum PCB

Aluminum PCB has excellent heat dissipation, insulation, and durability. Therefore, aluminum circuit board is widely used in industries such as aluminum LED lamp, driving devices for automobiles, computers, audio equipment, and power systems.

The aluminum PCB manufactured by iPCB uses halogen-free green and environmentally friendly boards to ensure full compliance with environmental requirements. There are thermal conductivity coefficients of 1.0W/mK, 2.0W/mK, and 3.0W/mK. There are three standard copper thicknesses: 35um, 70um, and 105um. meet the thermal conductivity and mechanical performance requirements of aluminum PCB for different industries and customers.

Product: Aluminum PCB

Material: aluminum substrate

Layer: 1

Color: White/Black

Finished thickness: 1.6mm

Copper thickness: 1oz

Surface treatment: OSP

Minimum line width: 8mil

Minimum spacing: 10mil

Thermal conductivity: 1-3W/mK

Application: LED Lamp

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.