Digital devices are developing towards high speed, low power consumption, small size, and high anti-interference. This development trend has put forward many new requirements for the design of circuit boards. Protel software has been widely used in China.

However, many designers only focus on the distribution rate of Protel software and improve it to regulate changes in device characteristics, which not only leads to more serious waste of software resources but also improves the performance of many new devices. It's hard to play. This article introduces the general requirements for high-frequency circuit wiring. Taking Protel for Windows v1.5 software as an example, this article introduces some special countermeasures that Protel software can provide in high-frequency circuit wiring.

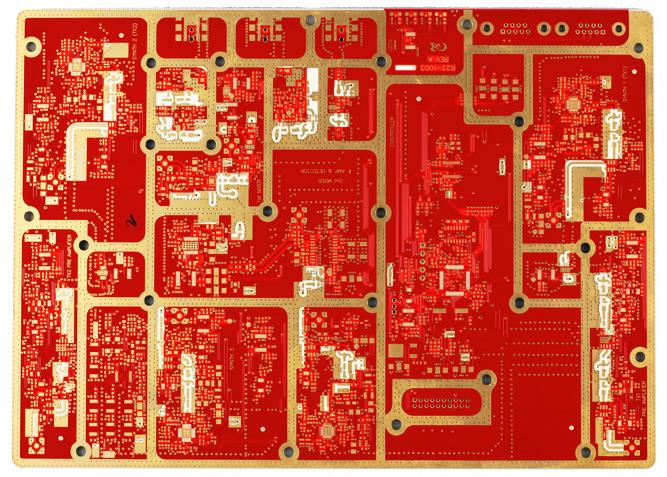

RF PCB

Application of Protel Software in RF PCB Circuit Routing

The main results are as follows:

(1) High frequency circuits often have high integration and high line density. Protel for Windows v1.5 can provide 16 copper layers and 4 power layers. Reasonable layer selection can greatly reduce the size of printed circuit boards, fully utilize intermediate layer shielding, better achieve nearby grounding, effectively reduce parasitic inductance, shorten signal transmission length, and greatly reduce cross interference between signals. All of these are beneficial for the reliable operation of high-frequency circuits. The results show that the noise level of the four layer board is 20dB lower than that of the double-layer board made of the same material, but the more layers there are, the more complex the manufacturing process and the higher the cost.

(2) The smaller the lead bending between high-speed circuit pins, the better. It is best to use a straight line for the lead out of high-frequency circuit wiring, and a 45 ° bend or arc is required. This requirement is only used to improve the fixed strength of steel foil in low-frequency circuits, but meeting this requirement in high-frequency circuits can reduce external transmission and coupling of high-frequency signals. When using Protel for routing, you can preset it in two places: one is to reserve 45/90 lines or 90 arcs in the "Trajectory Mode" submenu of the "Options" menu, and the other is to choose to add arcs. In the "Routing Channel" dialog box opened by setting the automatic routing option in the "Auto" menu, form an arc at the corner of the automatic routing.

(3) The shorter the leads between the pins of the RF PCB circuit, the better. The most effective method for PROTEL to meet the shortest path is to reserve a path for the single key high-speed network before the automatic market line. Firstly, in the sub menu of the netlst menu in editnet, the changenet dialog box will appear, where the optimization method and routing optimization mode can be selected as the shortest. Secondly, when considering the overall layout of the parts, use the mounting tool shoe to compare and adjust the components in Auto and the density in Auto to make them compact. By combining the length function of the netlist menu and the length selection function of the info menu, the wiring length of the selected key network can be measured.

(4) The less alternating the lead layers between the pins of high-frequency circuit devices, the better. The so-called lead layer alternation refers to the fact that the fewer through holes used in the component connection process, the smaller the 0.5pf distributed capacitance brought by the measurement holes. By reducing the number of holes, the speed can be significantly improved. Protel software specifically provides this feature. There is an advanced bar in the routing pass dialog box opened in the setup autoroute project of the auto menu, which can enable smoothing.

(5) Pay attention to the cross interference caused by short distance signal lines in high-frequency circuit wiring. If parallel distribution cannot be avoided, interference can be greatly reduced in a large area opposite the parallel signal line. Parallel lines in the same layer are almost inevitable, but the direction of straight lines walking in adjacent layers must be perpendicular. This is not difficult to achieve in Protel, but it is easily overlooked. In the wiring dialog box opened by the automatic routing option in the automatic menu settings, the direction of each layer can be predetermined. There are three types: "vertical" and "non preference". Users are accustomed to choosing no preference when there is no specific direction, so they consider the allocation rate to be very high. But in high-frequency circuit wiring, it is best to use horizontal and vertical wiring alternately in adjacent layers, which cannot avoid parallel wiring on the same layer. However, the ground wire can be placed on the opposite side of the printed circuit board to reduce interference. This is a common double-sided panel. Multilayer boards can use medium power layers to achieve this function.

Protel software only provides a simple filling function to meet this requirement. Now Protel also provides a more powerful feature in Windows, which is to place polygons, namely copper foil polygon meshes, in the placement options of the editing menu. If a polygon is placed on one side of the entire printed circuit board and the gate is connected to the GND network of the circuit, this function can achieve copper plating operation on one side of the entire circuit board. Laying copper circuit boards not only improves the high-frequency anti-interference ability mentioned above, but also has significant advantages in heat dissipation and PCB strength. In addition, if a tin plated mesh is added to the fixed part of the metal chassis of the circuit board, it can not only improve the fixing strength and ensure good contact, but also form a suitable common circuit using the metal chassis.