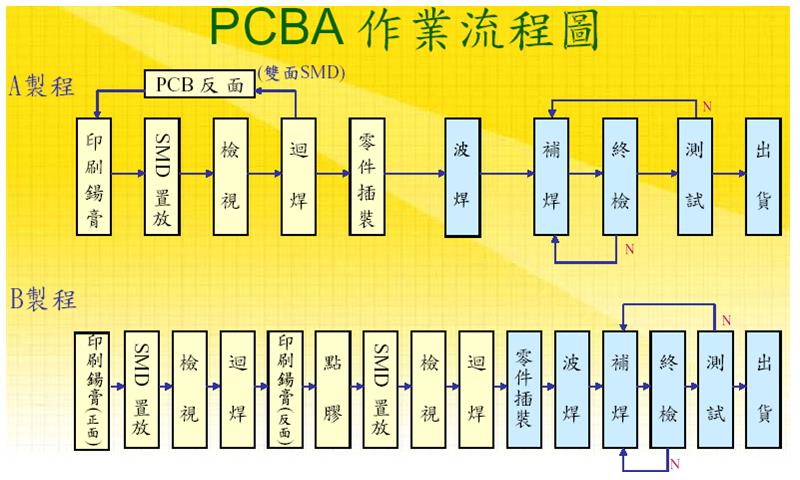

With the PCBA assembly of electronic products to miniaturisation,high assembly density direction,PCBA electronic assembly technology is also based on surface SMT mounting technology. However, there are still a certain number of through-hole insert components in some PCB circuit boards.The assembly of inserted components and surface-mounted components is called hybrid PCBA assembly, or hybrid assembly for short, and the assembly using all surface-mounted components is called full-surface mounting.

PCBA Assembly Process

PCBA assembly process and its method mainly depends on the type of assembly components and assembly conditions. It can be roughly divided into four types: single-sided mounting technology, single-sided hybrid mounting technology, double-sided mounting technology and double-sided hybrid mounting technology.

Single-side mounting technology

Single-sided mounting refers to mounting all components and assembling them on one side of the PCB.

The main flow of single-sided mounting process: printing solder paste → mounting → reflow soldering → cleaning → checking → repairing.

Single Side Mixed Assembly Process

Single-sided mixed assembly refers to both paste components and plug-in components, components are assembled on one side of the PCB.

The main flow of single-sided mixed assembly process: printing solder paste → paste → reflow soldering → insertion → wave soldering → cleaning → test → rework.

Double-sided mounting process

Double-sided mounting refers to the assembly where all components are mounted and the components are distributed on both sides of the PCB.

The main flow of double-sided mounting process: A-side printing solder paste → paste → reflow soldering → insertion → pin bending → board reversal → B-side dot paste adhesive → paste → curing → board reversal → wave soldering → cleaning → inspection → rework.

Double Side Mixing Process

Dual-side mixed assembly refers to the assembly of components with paste components and plug-in components, and the components are distributed on both sides of the PCB.

The main flow of double-sided mixed assembly process: A-side printing solder paste → paste → reflow soldering → plug-in → pin bending → reverse board → B-side dot paste adhesive → paste → curing → reverse board → wave soldering → cleaning → inspection → rework.

SMT Proofing

In order to realise the function of a product, it is impossible to complete it just by relying on a piece of PCB, and it is necessary to mount, insert and weld the components on the PCB board, and this step-by-step process is the PCBA assembly process. There are four major processes in the PCBA process.

Technically, the PCBA process can be roughly divided into four main processes, namely: SMT mounting processing → DIP insert processing → PCBA testing → finished product assembly.

SMT Punching Process

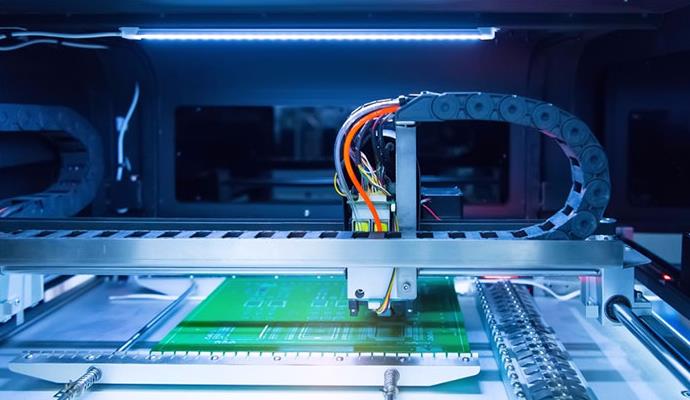

The SMT mounting process is generally based on the BOM list provided by the customer to match the components for purchasing and confirm the PMC plan for production. After the preparatory work is completed, the SMT programme design will be started,and the laser stencil and solder paste printing will be made according to the SMT process.

The components are mounted onto the circuit boards by SMT punching machines and, if necessary, are subjected to in-line AOI automatic optical inspection. After inspection, the perfect reflow oven temperature profile is set to allow the boards to flow through the reflow process.

After the necessary IPQC inspection,the DIP insertion process can then be used to insert the insert material through the board and then flow through the wave soldering for soldering. Then the necessary post-furnace process is carried out.

After the above processes are completed,QA is also required to carry out a comprehensive inspection to ensure the product quality passes.

DIP insert process

The process of DIP insertion flow is as follows:insertion→wave soldering→cutting foot→post-soldering process→board washing→quality inspection.

Semi-finished product PCBA test

PCBA test is the most critical quality control link in the whole PCBA processing process, which needs to strictly follow the PCBA test standard and test the test points of the circuit board according to the test plan of the customer.

PCBA testing also includes five main forms:ICT testing,FCT testing, aging testing, fatigue testing, and testing in harsh environments.

Finished Product Assembly

The tested PCBAs are assembled and then tested, and finally shipped.

PCBA assembly manufacturing is a ring by ring,any one link has a problem will have a very big impact on the overall PCBA quality, need to carry out strict control of each assembly manufacturing process.

IPCB share about the four main processes of PCBA manufacturing technology, each of its major processes have countless small processes to do to assist, each small process will have a test process or some to ensure the quality of PCB products,to avoid unqualified PCBA products out of the factory outflow.