Now more and more circuit boards use surface mount components, compared with the traditional packaging, it can reduce the area of the circuit board, easy to process in large quantities, high density wiring. The lead inductance of SMD resistors and capacitors is greatly reduced, which has great superiority in high frequency circuits. The inconvenience of surface mount components is that it is not convenient for manual soldering. To this end, this paper introduces the basic soldering method of surface mounted components, taking the common PQFP package chip as an example.

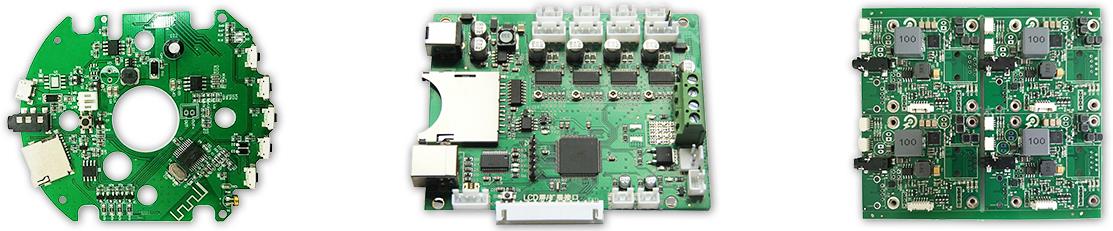

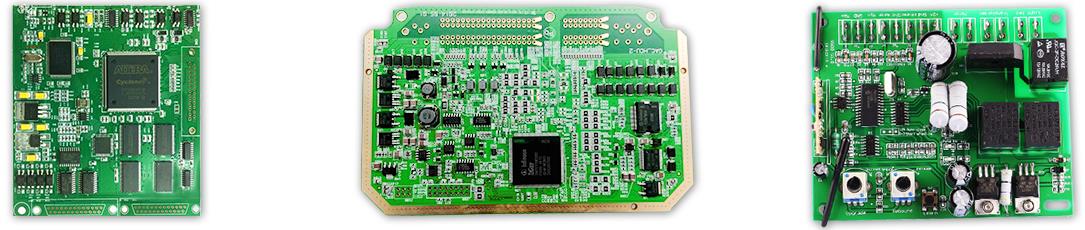

PCBA

I. Required tools and information

Soldering tools include a 25W copper-tipped soldering iron,a temperature-adjustable and ESD-protected soldering station if available, and a fine tip with a top width of no more than 1mm. A pair of tweezers with a pointed tip can be used to move and hold the wafers as well as to check the circuitry.You should also have fine soldering wires and flux, isopropyl alcohol, and so on. The purpose of the flux is to add fluidity to the solder so that it can be pulled by the soldering iron and wrapped smoothly around the pins and pads by surface tension.Use alcohol to remove the flux from the board after soldering.

II. Soldering Methods

(1) Before soldering, apply flux to the pads and treat them with a soldering iron,so as not to cause bad soldering due to poor tinning or oxidization of the pads, while the wafers generally do not need to be treated.

2) Use tweezers to carefully place the PQFP chip onto the PCB board, taking care not to damage the pins. Align it with the soldering pad and make sure that the wafer is placed in the correct direction. Adjust the temperature of the soldering iron to more than 300 degrees Celsius, dip the tip of the soldering iron with a small amount of solder, use the tool to press down on the chip that has been aligned position, add a small amount of solder on the pins of the two diagonal positions, still press down on the chip, solder the pins of the two diagonal positions, so that the chip is fixed and can not be moved. Re-check the position of the chip after the diagonal soldering to make sure it is aligned. If necessary, adjust or remove and reposition the chip on the PCB.

3) When you start to solder all the pins,add solder to the tip of the soldering iron and coat all the pins with solder flux to keep the pins moist. Touch the tip of the soldering iron to the end of each pin of the chip until you see the solder flowing into the pin. Keep the tip of the soldering iron parallel to the pin being soldered to prevent overlap due to excessive soldering.

4) After soldering all pins, wet all pins with solder flux to clean the solder. Wick off excess solder where needed to eliminate any shorts and laps. Finally, use tweezers to check for any loose solder. Once this is done, remove the flux from the board by rubbing a stiff bristle brush soaked in alcohol carefully in the direction of the pins until the flux is gone.

(5) SMD resistive components are relatively easy to weld some, you can first in a soldering point on the tin, and then put on a electronic component of the head, tweezers clamped components, welded on the head of the head, and then look at whether to put the right. If it's in the right place, then solder the other end. It takes a lot of practice to really master the art of soldering.

PCBA