As technology continues to advance, the biomedical testing field has an increasing demand for highly accurate and reliable detection methods. Ceramic circuit boards with interdigitated electrodes (IDEs) are emerging as key components in electrical signal transmission, playing an increasingly important role in biomedical testing.

Working Principle of Ceramic Circuit Boards and Interdigitated Electrodes

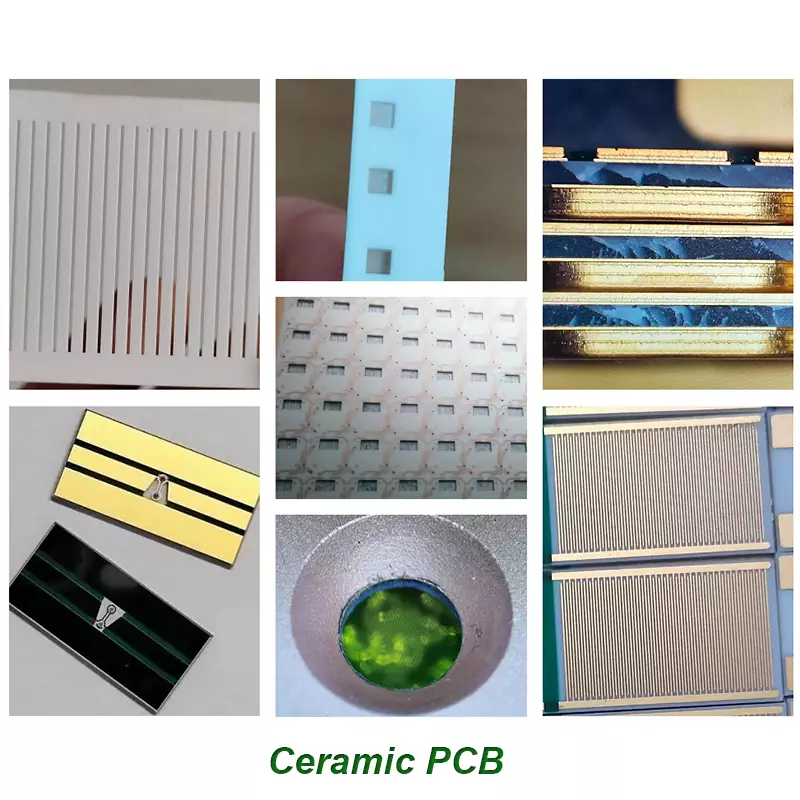

Ceramic circuit boards are created using ceramic materials like alumina and silicon nitride as substrates. Techniques such as printing and photolithography are employed to fabricate specific circuit patterns on the boards. The high insulation, stability, and heat resistance of ceramic materials provide the reliability required in biomedical testing.

Interdigitated electrodes are periodically arranged metal electrodes processed on substrates like ceramics or glass through electrochemical methods. These electrodes exhibit excellent conductivity and electrochemical characteristics, enabling precise signal transmission and measurement. In biomedical testing, IDEs are often used to construct microelectrode arrays for precise stimulation of cells and electrical signal collection.

Applications of Ceramic Circuit Boards and Interdigitated Electrodes in Biomedical Testing

Electrochemical Detection: Used in electrochemical detection platforms like enzyme-linked immunosorbent assays (ELISAs) or glucose sensors. The IDEs specifically identify biomolecules and, combined with the signal transmission capability of ceramic circuit boards, achieve highly sensitive and selective detection.

Cell Stimulation and Imaging: By constructing devices for cell culture and stimulation, IDEs can control electrical signals to stimulate cells, enabling monitoring and imaging of cellular physiological activities.

Microfluidic Chips: IDEs can be integrated with microfluidic technology to create chips for high-throughput detection, separation, and analysis of biological samples.

Biosensors: Used in sensors such as immunosensors or DNA sensors, IDEs and ceramic boards facilitate real-time monitoring of biomarkers and assist in disease diagnosis.

Advantages of Ceramic Circuit Boards and Interdigitated Electrodes in Biomedical Testing

High Stability: They maintain stable performance in complex environments.

High Insulation: Effective in preventing interference from stray signals.

Corrosion Resistance: Suitable for biomedical applications that require durability.

Precision: Capable of producing intricate circuit patterns and electrode arrangements.

Sensitivity: Achieve highly sensitive signal transmission and measurement, meeting the demands of biomedical testing.

Limitations of Ceramic Circuit Boards and Interdigitated Electrodes

High Production Costs: The manufacturing process is complex, requiring expensive equipment and materials.

Challenges in Mass Production: Scaling up production demands specialized technology and management.

Limited Mechanical Strength: Ceramic materials are brittle and prone to damage from impact or vibration.

Biocompatibility Needs Improvement: While ceramics offer advantages in biomedical testing, further research is needed to enhance their biocompatibility.

Future Developments of Ceramic Circuit Boards and Interdigitated Electrodes

Cost Reduction: Research and process optimization are expected to lower production costs and improve commercial feasibility.

Mass Production: Optimizing workflows and management could enhance mass production capabilities to meet growing market demand.

Improved Mechanical Strength: The development of new ceramic or composite materials could increase durability.

Enhanced Biocompatibility: Surface coatings or modifications could improve compatibility with biological molecules and reduce immune reactions.

Interdisciplinary Collaboration: Continued collaboration across fields like biomedicine, materials science, and electrochemistry will drive innovation and applications.

New Materials: The emergence of new ceramic materials with improved mechanical strength, thermal stability, and biocompatibility will open up more possibilities.

Advances in Micro/Nano Manufacturing: Precision and size will further improve, allowing ceramic boards and IDEs to be applied in smaller biomedical devices, enhancing sensitivity and reducing detection limits.

Multifunctional Integration: Besides electrical signal transmission, integrating other functional elements such as microfluidic channels or optical sensors will provide more comprehensive and convenient solutions for biomedical testing.

Online Detection and Real-Time Monitoring: With the growth of the Internet of Things (IoT) and cloud computing, real-time data transmission and analysis will enhance early disease diagnosis and treatment.

Process Optimization: As production techniques improve, costs will decrease, and mass production feasibility will rise, promoting widespread adoption in biomedical testing.

Ceramic circuit boards and interdigitated electrodes, as advanced signal transmission components, hold great potential in biomedical testing. Although there are challenges in current applications, continuous research and innovation will enable broader utilization in this field. Interdisciplinary cooperation, mass PCB production, and performance optimization will be key areas for future growth.

With the ongoing development of technology, the demand for advanced detection techniques in biomedical testing continues to rise. Ceramic circuit boards and interdigitated electrodes, as high-performance components for electrical signal transmission and measurement, will play an increasingly significant role in the field of biomedical testing.