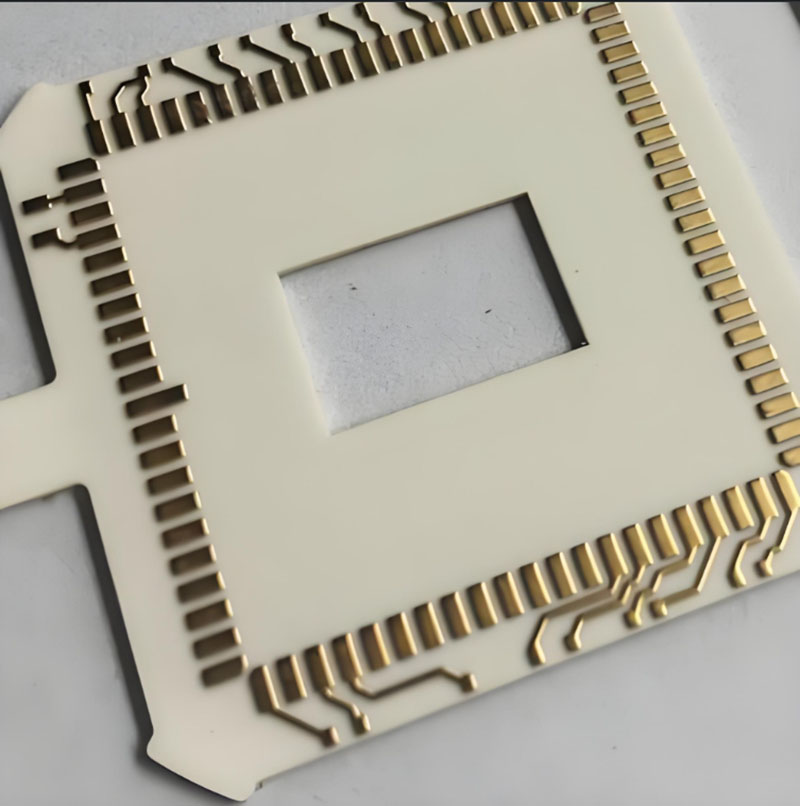

Ceramic board is also called ceramic substrate, ceramic PCB board, ceramic copper clad board. Ceramic substrate refers to a special process board in which copper foil is directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate or other ceramic substrate surface (single or double sides) at high temperature. The ultra-thin composite substrate has excellent electrical insulation properties, high thermal conductivity, excellent soft solderability and high adhesion strength, and can be etched with various patterns like pcb board, with great current carrying capacity. Therefore, ceramic pcb board has become the basic material for high-power power electronic circuit structure technology and interconnection technology.

When it comes to ceramic pcb, you may think of tiles and ceramic porcelain, but in the pcb industry, what we call ceramic is "fine ceramic (also called advanced ceramic or new ceramic)", which is an engineering material whose chemical composition is precisely adjusted by using refined or synthetic raw material powder and well-controlled molding, sintering and processing methods.

We usually regard ceramic board (printed circuit board) as a metal core pcb. It is important to understand that in many applications the use of FR4 boards or Metal Core Printed Circuit Boards (MCpcb) such as Aluminum Substrates and Copper Alloy pcbs is indicated and perfectly acceptable. However, in some applications, we recommend that you use ceramic boards to avoid putting your product at risk.

Advantages of Ceramic PCB boards

1. Ceramic pcbs have very good thermal conductivity and insulation properties. Ceramic pcbs are made of ceramic substrates. The ceramic substrate itself has very good insulation and thermal conductivity, with a thermal conductivity of 25~230w and very good insulation properties.

2. The dielectric constant of ceramic pcbs is very low, the dielectric loss is small, and it has very good high-frequency performance, small dielectric loss, and good high-frequency performance. It is widely used in the field of high-frequency communications.

3. The dielectric constant of high-frequency ceramic pcbs is generally at least 5, and the dielectric constant must be stable. It is more difficult to make high-frequency ceramic pcbs with a dielectric constant lower than 5. Generally, a high dielectric constant of 10 or higher is required. The specific amount should be determined according to the high-frequency needs.

4. Ceramic pcbs are resistant to high temperatures, corrosion, and environmentally friendly. They can work at high frequencies for a long time in very complex environments and have a long service life.

Disadvantages of ceramic pcb boards

1. Ceramic pcbs are small in size, generally less than 127mm in size, and specially customized to 200mm and 230mm. They are generally expensive and have high board costs. In addition, because ceramic pcbs are made of ceramic materials, they do not have better toughness like FR4 boards and can be made more than one meter long. In addition, ceramic pcbs are easy to break during processing, and the scrap rate is high, about 20%.

2. The production cycle of ceramic boards is long and the process is complex.

Application fields of ceramic pcb boards

1. Aerospace

In the field of aerospace, ceramic circuit boards have become an important choice for electronic equipment manufacturing in this field due to their excellent high temperature resistance, corrosion resistance, and radiation resistance.

2. Automotive industry

As a highly reliable and harsh environment resistant electronic component, ceramic circuit boards are widely used in key parts such as engine control, chassis control, and safety system control.

3. Energy field

Ceramic circuit boards have excellent high temperature resistance and corrosion resistance, and can adapt to high-intensity work in extreme environments.

4. Medical equipment

In medical imaging equipment (such as CT, MRI, etc.), ceramic circuit boards are used in key parts such as signal processing and image generation. In addition, ceramic circuit boards are also used in the electronic control systems of various medical devices (such as surgical instruments, therapeutic equipment, etc.).

5. Communication electronics

In mobile communication base stations, satellite communication equipment, radar and other communication systems, ceramic circuit boards are used in key parts such as signal processing and power amplification. In addition, ceramic circuit boards are also used in the manufacture of various communication protocol converters, optical fiber communication equipment and other high-end communication products.

6. Consumer electronics

In the manufacturing of home appliances such as TVs, stereos, and game consoles, ceramic circuit boards are used in key parts such as signal processing, power management, and control circuits. In addition, ceramic circuit boards are also used in the manufacturing of various digital products, such as mobile phones, tablets, and laptops.

7. Industrial control

Used in key parts such as signal processing and control circuits. In addition, ceramic pcb boards are also used in the manufacturing of various industrial instruments, such as pressure gauges, temperature gauges, flow meters, etc.

When choosing a ceramic pcb manufacturer, please consider cost optimization, material usage, delivery time, etc. ipcb is your preferred partner because we follow the latest IPC standards and tolerances and DFM rules to better suit your next upcoming ceramic board design.