Nowadays,electronic ceramic substrates are in full bloom. Here are some types, performance and applications of ceramic substrates.

Currently the most widely used,the advantages of ceramic substrates are:

Thermal properties: strong heat resistance and thermal conductivity.

Mechanical properties: high strength and hardness.

Other features: high electrical insulation, strong corrosion resistance, and high biocompatibility.

The mainstream application markets of LED are mainly white light, infrared and vcsel. This kind of 3-5W power optoelectronic product. The efficiency of aluminum oxide is higher than that of ordinary LED brackets (mainly heat dissipation). Compared with the low cost of other circuit boards, it has harvested this market like crazy. Additionally, some sensors are in use. They require the stability of ceramic substrates (corrosion resistance, long service life, high strength) and thrive in the sensor market of the future.

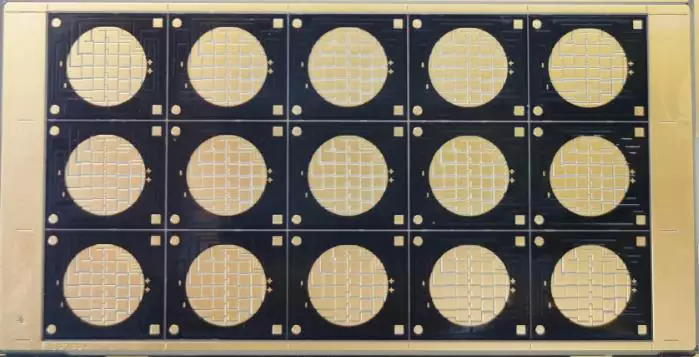

Ceramic substrate

The mainstream application markets are in the fields of high-power LEDs,power modules and lasers.Compared with alumina,aluminum nitride is also a mainstream ceramic circuit board substrate. But at present, aluminum nitride is only used in high-power LEDs such as stage lights,lamps,projector lights,and ultraviolet rays.In addition,semiconductor lasers and DC-DC power modules.First, these products have relatively high thermal management requirements and require high thermal conductivity substrates to help them dissipate heat.The other is that the wafer material of these products is silicon,and the thermal expansion coefficients of the wafer and aluminum nitride ceramics are closer. The two are combined in thermal deformation and will not change or fall off, allowing for better use of the wafer.In the future, aluminum nitride will be used in more and more applications. As products become smaller and smaller, their functions will become more and more powerful,and the requirements for substrates will become higher and higher. High thermal conductivity is a topic that can never be avoided. Currently, aluminum nitride is the most cost-effective ceramic substrate.

Silicon nitride ceramic substrate

Currently used in power electronic modules,it has the advantages of high mechanical strength, good toughness, and good thermal conductivity.

The cost of silicon nitride is higher than that of aluminum nitride substrates, and the thermal conductivity exceeds 80.Silicon nitride is mainly used in power electronic modules,such as IGBT modules, automotive modules,military industry,and aerospace modules.Mainly for its high mechanical strength and toughness.At present,due to the excessive current of the power module,the required copper thickness is relatively high (at least 500um).Judging from the product applications we are currently doing, subsequent applications of silicon nitride require very low copper thickness (some IGBT modules require low current)

Silicon carbide ceramic substrate Advantage

Silicon carbide can even maintain its strength at temperatures up to 1400°C.

A distinctive feature of this material is the extremely high thermal conductivity and electrical conductivity of power transistors.

Silicon carbide has high hardness and corrosion resistance due to its chemical and physical stability.

Today iPCB will introduce to you the types and applications of ceramic substrates.