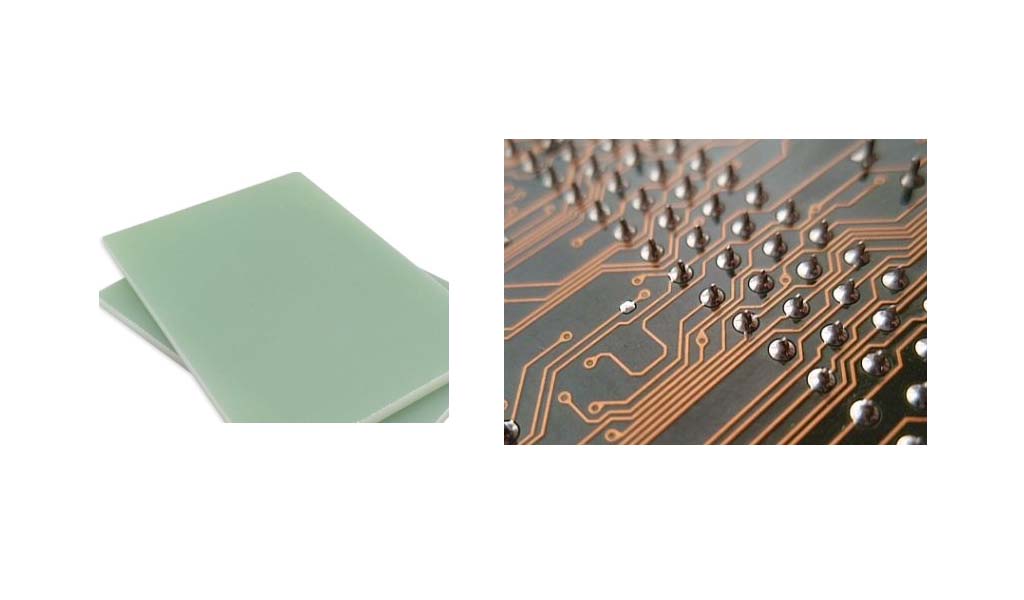

"Glass Epoxy" in pcb glass epoxy usually refers to a material used to make printed circuit boards (PCBs), also known as glass fiber reinforced epoxy resin. This material is usually a composite material formed by laminating one or more layers of glass fiber fabric impregnated in epoxy resin. On the surface, there are lines, and on the side, there are fiber filaments and cross-laminated.

Glass Fiber: Glass fiber is a material with high strength and heat resistance, widely used to reinforce composite materials. It can increase the mechanical strength and heat resistance of PCB substrates.

Epoxy Resin: Epoxy resin is a material that is resistant to chemical corrosion and high temperature and has good electrical insulation properties. It acts as a matrix of glass fiber in PCBs to play a bonding and protective role.

Applications:

1. Printed Circuit Board: glass epoxy is one of the most commonly used substrate materials in PCB manufacturing, especially in multi-layer circuit boards and high-frequency, high-performance circuits. A common example is FR-4, a glass fiber reinforced epoxy laminate with excellent mechanical and electrical properties, which is widely used in circuit boards for electronic products. In addition to PCB substrates, glass epoxy can also be used for electromechanical equipment insulators, fixtures and fixtures, and high-strength composite parts.

2. Electronic component packaging: Glass fiber epoxy is also widely used in encapsulating semiconductor devices and other electronic components. It can provide protection, isolation and fixation, and has good chemical and high temperature resistance.

3. Aerospace: Glass fiber epoxy is widely used in the aerospace field due to its light weight, high strength and impact resistance, such as manufacturing aircraft parts or rocket parts.

4. Automotive industry: In the automotive industry, glass fiber epoxy is also commonly used in the manufacture of automotive parts, such as hoods, body components, etc. It not only reduces the weight of the car, but also provides better impact resistance.

The main performance characteristics of glass epoxy are:

Flame retardant

Strong and hard

Dimensionally stable

Excellent electrical properties

Creep resistance

Advantages of pcb glass epoxy:

1. Excellent mechanical properties: Glass fiber reinforced epoxy PCB has excellent bending and tensile resistance.

2. Good electrical properties: This type of PCB has good dielectric properties, which can effectively isolate the circuit and provide stable and reliable electrical connections.

3. High temperature resistance: Glass fiber epoxy PCB can maintain stable operation at higher temperatures and has good heat resistance.

4. Low water absorption: Compared with other substrates, glass fiber epoxy PCB has a lower water absorption rate, which makes it stable in humid environments.

Disadvantages of pcb glass epoxy:

1. Fragile: Due to its hardness and brittleness, it is prone to mechanical damage or breakage during handling.

2. High processing complexity: Compared with soft substrates, this hard substrate requires more complex and precise processing, so the production cost may be higher.

3. Not suitable for bending design: Compared with flexible PCB, it has limitations when bending or twisting shape design is required.

Overall, PCB glass epoxy is still a popular and widely used choice in many application fields. Especially in high-demand application scenarios such as communication equipment, computers and industrial control systems.