PCB antenna refers to the PCB part used for wireless reception and transmission. With the emergence of 5G networks, more and more electronic devices require antenna PCB. An antenna is a sensor that converts the high-frequency current from the transmitter into spatial electromagnetic waves during transmission and sends them into the receiver. A good antenna PCB can optimize communication distance.

The antenna PCB data should have high frequency, while FR-4 PCB usually does not have good performance. The commonly used boards for antenna PCB manufacturing include Rogers PCB, PTFE PCB Arlon PCB、Taconic PCB、Nelco PCB、FR-5 PCB、 DuPont PCB, Isola PCB, etc.

What are the classifications of antenna PCB?

Antenna PCB are divided into two categories. external antenna and built-in antenna.

The length of an external antenna is about a quarter of the wavelength of electromagnetic waves, so the lower the signal frequency, the longer the antenna length. The 433MHz wireless serial port commonly used in the Internet of Things also uses an external antenna. Some antenna, such as one eighth or one sixteenth wavelength, can also be used, but their efficiency will be reduced.

For small products such as mobile phones, wearable designs, smart homes, etc., built-in antenna are usually used, with high integration, beautiful product appearance, and slightly lower efficiency than external antenna.

The built-in antenna includes PCB antenna, FPC antenna, WiFi antenna, etc.

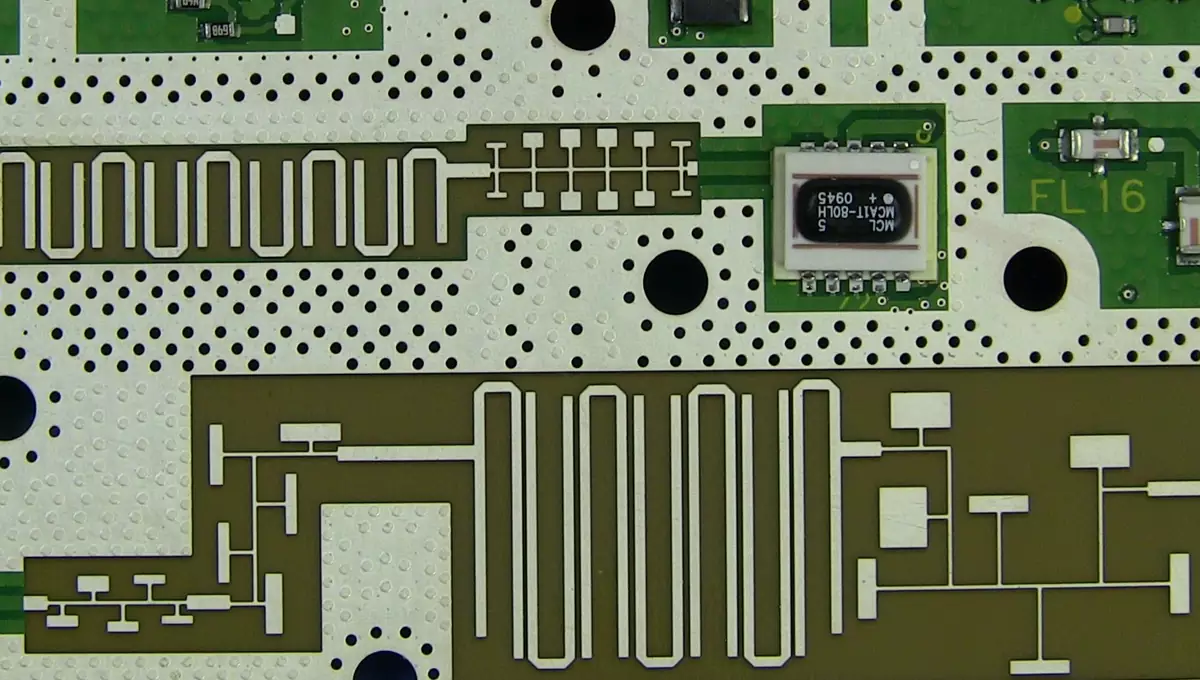

1. Inner true PCB antenna. a conductor directly arranged on the PCB circuit board, widely used in single frequency module circuit boards, such as Bluetooth modules, WIFI modules, ZIGBEE modules, etc.

Advantages. No cost, no need to debug again after tuning.

Disadvantage. Only applicable to a single frequency band, such as Bluetooth and WiFi. The performance of PCB antenna from different batches may vary.

2. FPC antenna. It is equivalent to pulling out the antenna line on the PCB board and using other external metals to make the antenna, usually used for mid to low end mobile phones and smart hardware products in complex frequency bands.

Advantages. Suitable for almost all small electronic products, with good performance and low cost.

Disadvantage. Each product requires separate debugging.

3. WiFi antenna. refers to a communication antenna with a working frequency between 2.4GHz and 2.5GHz, mainly used for WLAN, Bluetooth, etc. Wifi antenna PCB has strict requirements for PCB manufacturers.

Antenna PCB

What are the key points of antenna PCB manufacturing?

1. If cost and size are not considered for PCB antenna, other antenna can be chosen, such as patch antenna (small size, medium efficiency, medium cost) or external whip antenna (large size, high performance, high cost).

2. The dielectric constant (Dk) of circuit laminates is the primary factor that many PCB antenna engineers should consider when designing microstrip antenna.

3. For PCB antenna, thicker PCB circuit boards are more likely to radiate energy outward.

4. Compared with ceramic or PTFE media in PCB laminates, the surface roughness of copper foil in laminates has an impact on antenna. Meanwhile, for circuits with the same dielectric material, the effect of rough copper foil surface on the antenna is greater than that of smooth copper foil surface.

5. After surface electroplating, PCB antenna and other passive components made from PCB data can also affect the performance of PCB antenna.

6. The presence of any form of ion pollutants or residues in the circuit may lead to poor antenna efficiency.

7. The etching quality of PCB circuit boards is also very important for the efficiency of antenna PCB.

As a carrier of high-speed signal transmission, antenna PCB play an increasingly important role in wireless communication and other fields. IPCB has a stable production process for producing antenna PCB. If you need antenna PCB manufacturing, please contact iPCB.