FR-4, also written as FR4, is both a name and a standard grade.

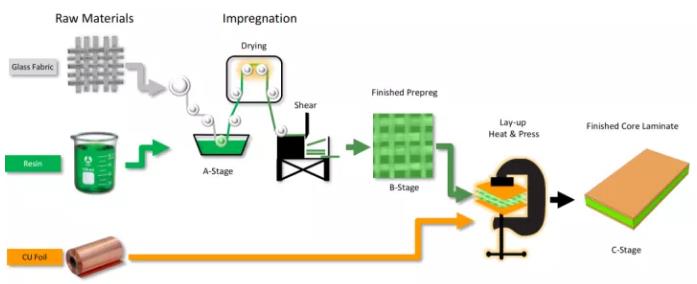

The FR-4 organic substrate material used in PCB manufacturing consists of three components: resin, reinforcement material, and conductive copper foil.

Composition of FR-4 Laminates

FR-4 is the name given to laminates that use glass fibre cloth as a reinforcing material and epoxy resin as the resin system in the manufacture of printed circuit boards.

FR-4 is just a general term for a class of boards. The glass fibre cloth is an electronic grade glass fibre that is woven into a thin, cloth-like material. The glass fibres give FR-4 the necessary structural stability. The glass fibre cloth is surrounded and bound by an epoxy resin with flame retardant additives. The resin gives the material its rigidity, among other physical properties.

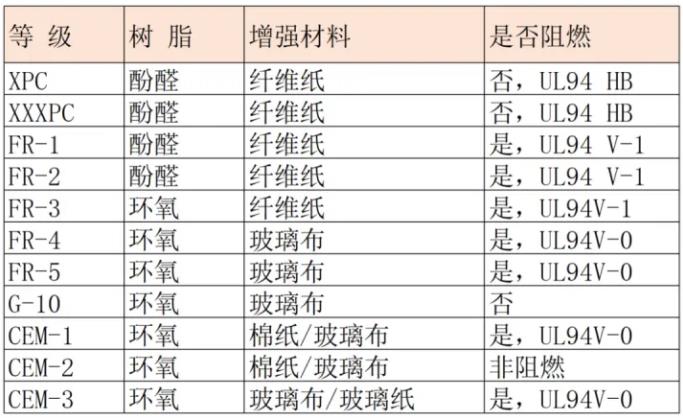

FR-4 specifications are set by NEMA (National Electrical Manufacturers Association), and the commonly used PCB substrate grades are categorised in the table below.

Composition of FR4

NEMA classification standards in the FR that Flame-Retardant (Fire-Retardant) or Fire-Resistant (Fire-Resistant), i.e., fire rating, so FR level of panels are flame-retardant panels, and the number of digits ‘4’ is the material and other materials of the same level to distinguish between 4,that is, the resin is epoxy resin, reinforcing material for glass fibre cloth for UL94 V-0 of such a class of panels. The number ‘4’ distinguishes the material from other materials of the same grade, 4 means that the resin is epoxy resin, the reinforcing material is glass fibre cloth, and the flame retardant grade is UL94 V-0. FR-1, FR-2, and FR-3 are UL 94V-1, with different resins and reinforcing materials.

In the 1950s, paper phenolic laminated copper substrates were introduced and used in a large number of radio and television sets and other electrical equipment, but this material has low electrical insulation and is not flame retardant. At that time, the United States occurred a number of fire accidents caused by electrical failure of television sets, so NEMA out of electrical safety considerations, divided into different levels of PCB substrates, mainly based on the circuit board substrate flammability, high temperature stability and moisture absorption, etc., but did not provide for substrate electrical performance, such as dielectric constant and loss angle tangent, etc., quotas.

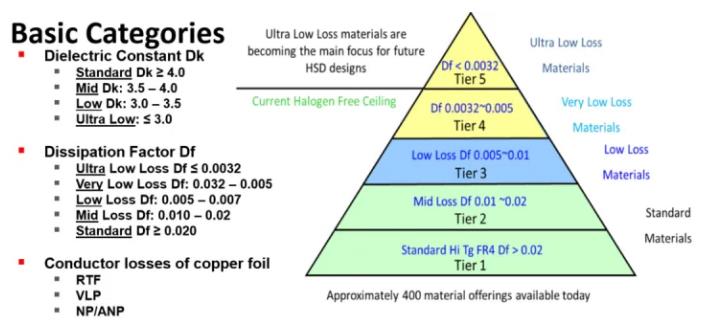

FR-4 is only one of the grades in the NEMA Substrate Grade Classification and represents a material class, not a specific material. A common problem is that FR-4 is often confused with a specific dielectric, for example, the FR-4 material in our simulation software has a default dielectric constant of 4.2 and a loss angle tangent of 0.02, but many low to medium loss boards are also FR-4 rated.

FR4 is a must-have in the stock of every PCB factory. Why is FR4 the most common material in PCB factories?

NEMA Classification Standards

The first widely used PCB boards were paper phenolic laminated copper substrates, such as XPC, XXXPC, because the price of the material is relatively cheap, but they are non-flame-retardant materials, in the 1970's after the emergence of fire accidents due to circuit failures, the major electrical equipment began to switch to the use of flame-retardant substrates, with flame-retardant characteristics of the paper phenolic laminated copper substrates FR-1, FR-2 used gradually overtook the non-flame-retardant XPC, XXXPC substrates. The use of FR-1 and FR-2 paper-based phenolic copper-clad substrates with flame-retardant properties gradually surpassed that of non-flame-retardant XPC and XXXPC.

In the 1980s, multimedia portable devices became popular, such as Walkman, BP machine, etc., PCB began to develop towards miniaturisation and high density, and the application of multi-layer PCB became more and more common, which in turn led to the development of PCB substrate materials.

Although paper substrates such as XPC and FR-1 are cheaper than epoxy glass fabric substrate FR-4, they are inferior to FR-4 in terms of moisture absorption, heat resistance and mechanical strength. In the early days, paper substrates were usually used for price-sensitive consumer products while FR-4 was more commonly used for industrial products.

However, as consumer equipment has evolved to become smaller, lighter and thinner, the use of FR-4 sheets has increased. As PCBs with a standard thickness of 1.6 mm to 0.8 mm become widely used, the mechanical strength and moisture resistance of paper substrates become a problem. In addition, the paper substrate is not suitable for the production of multi-layer boards, and with the development of equipment miniaturisation, PCB wiring density is getting higher and higher, the market share of multi-layer boards is also getting higher. In this regard, despite the relatively high cost of FR-4 boards, consumer products are still gradually shifted to FR-4 boards.

PCB moulding factory widely choose FR-4 and did not use the cheaper paper substrate another important reason is that the paper substrate is not suitable for drilling process, only suitable for punching process, and FR-4 is very easy to process.

With the continuous expansion of epoxy resins and glass fibre cloth, the standard FR-4 substrate is now a low-cost material with excellent mechanical performance and processability, making it popular with low and medium-cost electronics manufacturers around the world.

FR4 Performance Indicators

FR-4 substrates are epoxy resin systems, so the Tg value has long been the most common value used to classify FR-4 substrate grades, and is also one of the most important performance indicators in the IPC-4101 specification.

Glass transition temperature Tg

The Tg value of a resin system refers to the temperature change point at which the material changes from a relatively rigid or ‘glassy’ state to a deformable or softened state. This thermodynamic change is always reversible as long as the resin does not decompose. This means that when a material is heated from ambient to a temperature above the Tg value and then cooled below the Tg value, it can be returned to a rigid state with the same properties as before. However, when a material is heated to a temperature much higher than its Tg value, irreversible phase changes may result. The effect of such temperatures is highly dependent on the type of material and on the thermal decomposition of the resin.

In general, the higher the Tg of the base material, the higher the reliability of the material. The thermal decomposition temperature (Td) of the substrate also needs to be taken into account if lead-free soldering processes are used.

Other important performance indicators include Coefficient of Thermal Expansion (CTE), water absorption, material adhesion characteristics, and commonly used delamination time tests such as T260 and T288.

Diversity of FR4

Substrates using glass fibre cloth as reinforcing material, epoxy resin system and UL 94V-0 flame retardant rating are all FR-4, so what is the specific difference between such a large group of materials?

According to the Tg value

The most obvious difference between FR-4 materials is the Tg value. According to the Tg temperature, FR-4 sheets are generally classified into low Tg, medium Tg and high Tg sheets.

In the industry, FR-4 with a Tg of about 135°C is usually classified as a low Tg sheet; FR-4 with a Tg of about 150°C is classified as a medium Tg sheet; and FR-4 with a Tg of about 170°C is classified as a high Tg sheet.

If the PCB is processed with more pressing times, or more PCB layers (more than 14 layers), or high soldering temperature (≥ 230 ℃), or high working temperature (more than 100 ℃), or high soldering thermal stress (such as wave soldering), high Tg sheet should be selected.

Breakdown of FR4

FR-4 can be divided into:

Ordinary loss plate (Df≥0.02)

Medium loss sheet (0.01 Low loss sheet (0.005 Ultra low loss sheet (Df<0.005) Different FR-4 grade materials from different FR-4 sheet suppliers also have different performance differences, and there are also different product specifications under the same supplier's FR4 grade. Therefore, the most accurate designation of the selected FR-4 sheet needs to be accurate to the specific FR-4 material supplier's specific product model, such as ITEQ IT-180A, SangYi S1141.