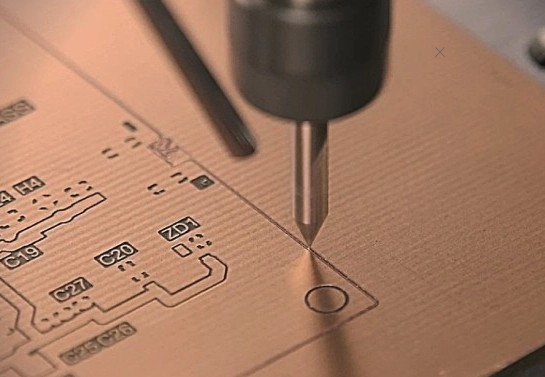

CNC PCB milling is a precise and efficient method of manufacturing printed circuit boards (PCBs) using computer numerical control (CNC) technology. This process accurately removes copper from PCB materials to create intricate designs, signal lines, and pads without hazardous chemicals.

CNC milling facilitates rapid prototyping, allowing designers to test and modify designs with shorter lead times than traditional methods. Milling tools used in CNC machinery typically have a minimum diameter of 0.8 mm, with a standard diameter of 2.0 mm. Special diameters in the range of 0.8 mm to 2.0 mm are also available to meet specific customer requirements. The correct tool is essential to ensure the accuracy and quality of the finished PCB, and the choice of tool diameter can significantly affect the accuracy of the milling process.

Types of PCB drilling:

1. Through-hole: Used for connecting conductive patterns between different circuit board layers, in addition to mounting components to ensure the proper functioning of the circuit.

2. blind holes: connecting the outermost layer of the PCB circuitry and the inner layer of circuitry, the bottom of the hole is not exposed on the surface of the circuit board.

3. buried holes: connection between the internal layers of the PCB, does not extend to the surface of the circuit board.

Hole Diameter Requirements:

1. through-hole minimum hole diameter is 6 mil, through-hole aspect ratio is generally 10:1, and the recommended design is 8 mil. Through-hole is usually used to mechanically drill holes.

2. Typically, blind and buried holes can be less than or equal to 0.15 mm, while laser-drilled holes are standardized to a minimum hole size of 0.1 mm with an aspect ratio 1:1.

CNC PCB milling is versatile and can be used in all aspects of PCB production, including cavity milling, cutting, and molding circuit boards. The process supports prototyping and small to medium-sized production runs, providing manufacturers with the flexibility to help them adapt to changing designs or requirements. The ability to handle both milling and cutting in a single setup simplifies operations. Nowadays, CNC PCB milling is expected to incorporate advanced automation and software features to further improve productivity and accuracy. Future developments may focus on integrating artificial intelligence and machine learning to optimize milling operations and predictive maintenance to improve the overall manufacturing process.

Laser drilling technology utilizes a high-energy laser beam for precision drilling, enabling high-density interconnections in a very small space, effectively improving board performance and reliability, and featuring high accuracy, fast processing, and low defect rates. In the future, HDI laser drilling technology may be combined with advanced automation and smart manufacturing technologies to improve productivity and reduce costs.