Printed Circuit Boards (PCBs) serve as the backbone of modern electronic devices, providing the platform for mounting electronic components and establishing reliable electrical connections. They are essential for ensuring the correct operation of devices, from consumer electronics to industrial systems. However, despite careful design and manufacturing, PCBs are susceptible to a variety of failures, which can compromise device performance, reduce reliability, and shorten the operational lifespan. Therefore, understanding the common types of PCB failures and adopting effective preventive measures is critical for engineers, manufacturers, and maintenance teams who aim to maintain high-quality, reliable electronic equipment.

1. PCB Cracking or Warping

Cause: PCB cracking or warping is often caused by excessive mechanical stress or environmental factors. Rigid PCBs, when exposed to repeated vibrations, thermal cycling, or physical bending, may develop cracks or deform. Even flexible PCBs have their limits; applying a force beyond their tolerance can result in permanent damage. Other contributing factors include improper handling during assembly, over-tightening of screws, or mounting in constrained enclosures that exert stress on the board.

Prevention: To minimize the risk of cracking or warping, PCBs should undergo pre-baking to remove residual moisture before assembly. Storing boards in humidity-controlled cabinets further prevents moisture absorption, which can exacerbate thermal stress during soldering. During assembly, care should be taken to avoid sudden impacts or bending, especially in the final stages. Proper fixture design during assembly and testing can also reduce mechanical stress on sensitive areas of the board.

2. Incorrect Polarity of Components

Cause: Polarity issues arise when components that are sensitive to electrical orientation—such as diodes, electrolytic capacitors, LEDs, or batteries—are installed incorrectly. Improper layout design, unclear marking of polarity, or assembly errors can result in reverse connections, potentially damaging both the PCB and the component. In some cases, this can create a safety hazard, including overheating or electric shock.

Prevention: To prevent polarity-related failures, designers can incorporate protective measures such as series diodes or Schottky diodes. By placing a diode in series with the power supply, reverse polarity conditions will prevent current from flowing, safeguarding the PCB and associated components. Clear polarity markings and automated optical inspection (AOI) during assembly can further reduce human errors.

3. Solder Joint Cracks

Cause: Solder joint failure is a common issue caused by mechanical stress, thermal cycling, or mismatched coefficients of thermal expansion between the PCB substrate and mounted components. Repeated exposure to high or low temperatures can induce fatigue in solder joints. Manual soldering or improper reflow profiles can further increase vulnerability to cracking.

Prevention: Proper component placement is crucial to minimize stress on solder joints. Heavy or vibration-prone components should be positioned away from critical solder points. Solder joints should be evenly distributed to avoid localized stress concentrations. During the design phase, engineers should select materials with compatible thermal expansion coefficients or employ buffer structures to absorb stress. Optimized thermal profiles during soldering and assembly can also enhance joint reliability.

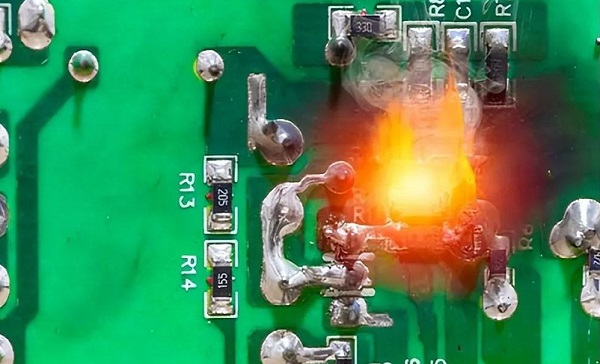

4. Component Burnout or Short Circuits

Cause: Short circuits are a major source of PCB failure and can result from solder bridges, moisture contamination, manufacturing defects, or unexpected current surges. Such failures can instantly damage components, compromise the entire PCB, and in severe cases, create fire hazards.

Prevention: Preventive measures include thorough visual inspections, electrical testing for shorts and opens, and comparison with baseline probe measurements. Designers can further enhance reliability by incorporating protective elements, such as fuses, transient voltage suppression (TVS) diodes, overvoltage and overcurrent protection devices, and proper grounding techniques. Adequate thermal management—through heatsinks, fans, and thermal vias—reduces overheating risks, particularly for high-power components such as amplifiers and power modules. Electromagnetic compatibility (EMC) considerations, including shielding, filtering, and careful layout, can further prevent component failure due to electrical interference.

5. Improper Copper Weight

Cause: Copper thickness is critical for ensuring that PCBs can carry required currents without overheating or excessive voltage drop. Too thin copper traces can overheat, while excessively thick traces may complicate manufacturing or impact thermal dissipation. Miscalculations in trace width or layer design often lead to copper weight issues.

Prevention: Engineers should calculate current requirements accurately and determine appropriate copper thickness for each circuit segment. Even current distribution can be achieved through thoughtful layout design, avoiding localized high-current areas that stress specific traces. Heat management is equally important; proper placement of thermal vias, heatsinks, and thermally conductive materials ensures heat is dissipated effectively. Adequate spacing between components and attention to airflow can further prevent hot spots that could compromise PCB performance and reliability.

Conclusion

PCBs are the cornerstone of electronic devices, and their reliability directly impacts the performance, safety, and lifespan of the equipment. By understanding the types and causes of PCB failures—including cracking, polarity errors, solder joint issues, component burnout, and copper weight problems—engineers and technicians can implement effective preventive strategies. Proper design, careful material selection, controlled assembly processes, and rigorous testing are essential for reducing failure rates. Ultimately, a proactive approach to PCB reliability ensures stable, efficient, and safe operation of electronic devices across applications.