With the development of electronic technology,PCBA highly integrated,PCBA on the components are more and more, smaller and higher density.The height between the device and the device (the distance between the device and the PCBA) is getting smaller and smaller, but the environmental factors on the PCBA impact is getting bigger and bigger, the reliability of the PCBA of the electronic products put forward higher requirements.

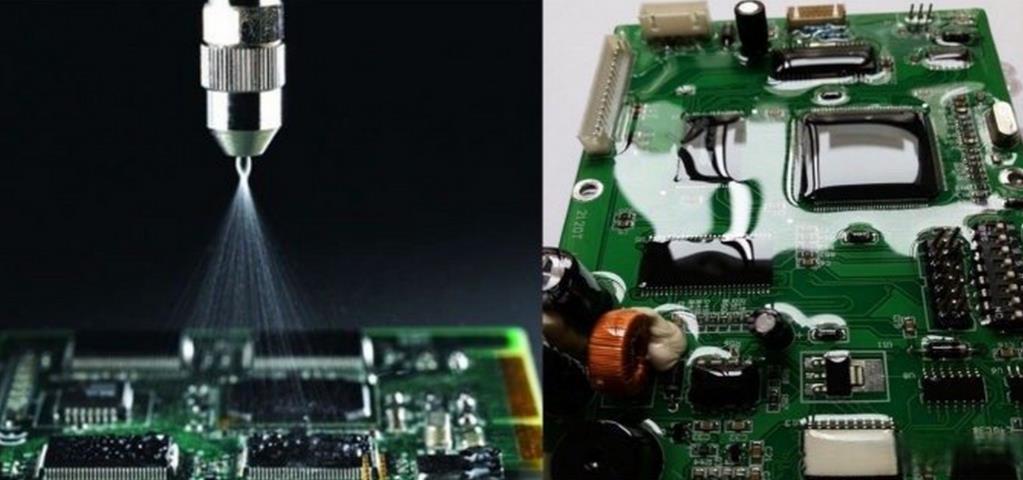

At this time it is necessary to use PCBA conformal coating processing technology to protect the PCB. Protective coating is applied to the PCBA on a layer of data, used to enhance the performance and reliability of PCB assembly, protect the PCBA from environmental hazards, extend the life of the product, and at the same time to improve the insulation characteristics and mechanical strength of the product.

Conformal coating is a specially formulated coating used to protect circuits and related equipment from environmental erosion. It is mainly used for the protection of integrated circuits of colour TVs, freezers, washing machines, air-conditioners and other common household electrical and electronic products. It has the performance of waterproof, lightning protection, anti-corrosion and so on. In addition, the three-proof coating can improve and extend the service life of household electrical appliances and other equipment to ensure the safety and reliability of use. Three-proof paint coating should cover the entire PCB board in addition to the key components, the sensitive electronic components and harsh environment isolation, to protect the circuit board from moisture, salt spray, mould and other factors. Avoid damage caused by friction or physical impact.

Conformal coating processing technology requirements

1.Conformal coating should be bright Flat.Thickness and thickness should be even.Patch components or conductor surface should be well protected.

2.The coated PCB should be clean.Clean and no component damage.

3.The surface of PCB should be free of air bubbles.Orange peel.Paint.Pinholes.Water ripples.Chalking and peeling.

Which parts of PCBA can not be coated with Triple Anti Varnish?

1.High power belt with heat sink or heat sink assembly.Power resistors.Power diodes and cement resistors.

2.Dip switches.Adjustable resistors. Buzzers.Battery holder. Fuse holders (tubes),IC holders and touch switches.

3.Plug-in or stick-on LEDs, digital tubes.

4.Screw holes in PCBA boards cannot be painted with triple-proof paint.

5.All types of sockets. Pins. Terminals and DB header.

6.Other parts and devices that cannot be insulated with varnish as stipulated in the drawings.

Conformal coating application areas

Typical applications of PCBA conformal coating processing include PCB circuit boards.Software printed electronic boards. Automotive electronic control boards. Electronic circuit boards. Home appliance controller and other industries.

PCBA Triple Varnish Storage

The storage of circuit board varnish is critical.Need to protect the effectiveness of the three-proof paint, for enterprises to save a lot of raw material costs.In this case, the good circuit board three anti paint storage is also PCBA manufacturers should pay attention to.Circuit board three-proof paint storage need to pay attention to what?

1.Pay attention to fire prevention, equipped with fire-fighting equipment.

2.The warehouse should be kept ventilated to prevent gas leakage and cause accidents.

3.The warehouse should be equipped with emergency equipment for leakage and reasonable storage materials, such as sand.

4.The effective use date should be indicated on the storage container of the circuit board triple-proof paint.

5.It should be stored in a cool and dry warehouse with room temperature not exceeding 30 degrees.Explosion-proof ventilation system and equipment should be installed, and away from heat sources.

6.The storage rack or equipment should be well grounded, and the equipment and tools that are prone to sparks should not be used.

7.Separate storage with other chemicals, clear labelling of information, avoid mixed storage.

Conformal coating process is widely used in contemporary circuit board coating work,in order to achieve the three-proof effect, that is, dustproof.Moisture.In order to achieve the three-proof effect, i.e.dustproof, moisture-proof and shock-proof, what techniques should be paid attention to when applying Tri-Proof Paint to achieve such effect?

Requirements for conformal coating

1.The conformal coating coating process should be carried out in a separate closed room, and the operation room must be well ventilated.

2.Smoking is prohibited in the operation room.Alcoholic beverages should not be consumed before work.

3.Wear a mask or gas mask when working.Rubber gloves.Chemical protective glasses and other protective equipment to avoid injury to the body.

4.After finishing the work of three-proof paint coating, the used instruments should be cleaned up in time, and the articles and equipment should be cleaned.Equipment should be cleaned and polished.The containers coated with three-proof paint should be covered tightly.

5.The workplace should be clean and dust-free,and unrelated personnel should not be allowed to enter.

6.The articles and equipments should be completely grounded and anti-static measures should be taken.

7.Do not stack PCBs during operation, PCBs should be placed horizontally.

8.Each batch of data should be carried out a small sample maintenance test before use.

Quality requirements of three-proof paint coating processing

1.PCB appearance should not have flowing paint.Drip.Semi-moist appearance.

2.Conformal coating layer should be flat.Bright.Uniform thickness,pads.The appearance of the paste or wire should be well protected.

3.The appearance of the paint layer shall not have orange peel.Air bubbles or ripples.

4.Equipment or parts that do not need protection do not need to be painted with conformal coating.

5.Printed circuit boards should be clean and tidy without damage after coating with conformal coating.

6.The board surface and equipment should be free of dirt.Fingerprints.Fingerprints.Shrinkage holes.Dust and other defects,no chalking and peeling of incoming materials.No chalking or peeling of incoming materials.

Advantages of conformal coating Processing

Tri-proof Paint is a specially formulated coating used to protect circuit boards and related equipment from environmental corrosion.Conformal coating has good resistance to high and low temperatures, and after curing, it forms a transparent protective film with excellent insulating properties.Moisture proof.Leak-proof.Shockproof.Dustproof.Anti-corrosion.Anti-aging.Resistant to corona and so on.Three-proof means: moisture-proof.Dustproof.Chemical corrosion resistance.What are the advantages of three-proof paint spray processing:

1.The amount of paint to be sprayed.Position and area setting precision.

2.There is no need to wipe the board after spraying.If the distance between some inserts and the edge of circuit board is bigger, it can be painted directly without fixture, which can save labour cost.

3.There is no gas evaporation to ensure the working environment is clean.

4.All substrates do not need to be covered with fixtures to eliminate the possibility of collision.

Can circuit board conformal coating work like resin? What is the difference between circuit board paint and resin?

(Conformal coating can really be used as resin!) Triple-proof lacquers can be applied using the simple application method of triple-proof lacquers, while at the same time providing the protective effect of resins.At the same time, they do not require the use of solvents and have the advantage of being environmentally friendly.2K coatings provide excellent coverage and are flexible enough to protect delicate parts.

Conformal coating also have excellent mechanical properties and abrasion resistance.Considering that the two-component chemistry is similar to resins, the coatings should be applied with selective coating equipment in the thickness range of 200 microns - 400 microns (0.2mm - 0.4mm),combining the various technological advantages of the two methods, while avoiding to the maximum extent possible the drawbacks of each.

The most obvious difference between conformal coating and resin lies in the method.The most obvious difference between three-proof paint and resin is the method of application.Varnish spraying equipment.Hand-held spray gun.Brushing method, etc.Resin encapsulation methods include hybrid dispensing equipment and resin encapsulation.The coating thickness of the data also varies (thickness < 100 microns for tri-proof paint, < 500 microns for 1% solid coating, > 500 microns for resin).International standards (IEC-1086).Military standard (MIL-I-46058C).Industry standard (IPC-CC-830).National safety standards (UL746) are recognised for the use of three-proof paint, but for resin, it depends on the specific application, and there are very few standards that can be referred to.

Because the thickness of the coating is much thinner than that of the resin,the volume and weight of the coating is smaller.The coating resin can be epoxy resin, polyurethane.Polyurethane.Silicone is the main type of coating resin,while acrylate coating.Acrylic coatings.Poly paraxylene coatings do not have corresponding resin data.99% of the resins are completely solid,so there is little or no VOC emission during the curing process.Whilst many tri-proof paints have a high solvent content, there are also 100% solid two component and UV cured acrylic systems.

What are the precautions for the use of PCBA conformal coating?

1.Viscosity changes:before and after the conformal coating processing will have different viscosity changes, the flow rate of the three-proof adhesive will change with the change in temperature.The higher the temperature, the faster the flow rate, this point must be clear.

2.Thickness of coating layer:If you want to get a thicker coating layer, it is better to apply two thinner layers to get it, and the first layer must be fully cured before applying the second layer;

3.Thickness of film layer:The thickness of film layer depends on the application method.If the amount of thinner added is large and the viscosity of glue is low, the thickness of coating is thin; on the contrary, if the viscosity of glue is high, the thickness of coating is thick;

4.Inconvenient coating area:some PCB components and equipment is not convenient coating, such as connectors.Software socket.Switch.Heat sink.Cooling area.Plug-in areas, etc.The following are not allowed to be coated materials.It is recommended to use peelable solder mask CS5001 to hide it;

5.Temperature and humidity:All coating work should be carried out at a temperature of not less than 16°C and a relative humidity of not more than 75%.As a composite material, PCBs absorb moisture.Without removing the moisture, DYNAM's triple-proof adhesive will not be able to provide adequate protection,and pre-drying and vacuum drilling can remove most of the moisture.

6.Coating Repair Method:To repair a coated device,simply remove the component device by placing the soldering iron in direct contact with the coating.After installing the new component equipment, clean the area with a brush or solvent [thinner],then allow it to become dry and apply the three-proof adhesive coating from the beginning.

7.Conformal coating generally contains flammable solvents:avoid high temperatures and open flames, satisfactory ventilation, long-term inhalation of volatile gases and long-term repeated contact with the skin.The processed PCB components coated with three-proof adhesive,fully cured,basically no harm to the human body;

8.Safety of operators:Pay attention to the safety and protection of three-proof adhesive spray processing work, the environment should be ventilated, and operators should wear protective gas masks.

Conformal coating processing of common problems cracks and scratches solution

Cracks in conformal coating are mainly due to the excessive thickness of the paint film and high surface tension,such as pins,component edges,etc.The solution is to reduce the thickness of the paint film, and to make it more durable.The solution is to reduce the thickness of the paint film,optimise the furnace temperature profile,keep the furnace temperature not too high,and let the paint film dry and cure slowly to achieve the best performance.Scratches come from tool or mechanical scratches during the coating process.Special attention should be paid during the coating drying and packaging process.

Cracking of the film is mainly caused by the accumulation of internal stresses under the action of environmental factors,such as volume shrinkage during curing or shrinkage at low temperatures, resulting in the formation of internal stresses.The film then undergoes hot and cold.After alternating cycles of heat and cold, dry and wet,the expansion coefficients of the coating and the substrate are different, resulting in the relative displacement of the interface, and thus the formation of destructive internal stresses.

Causes and solutions of cracking of conformal coating film

1.Reason:under low temperature,the film is easy to break,and the flexibility is poor.

Solution:Choose flexible conformal coating.

2.Reason:When mixing two-component conformal coating,the curing agent is too much, resulting in large shrinkage during curing.

Solution:Make the ratio of two-component conformal coating as accurate as possible.

3.Reason:Poor adhesion of paint film,for example,when low temperature produces shrinkage stress,poor adhesion will accelerate cracking.

Solution:Improve the adhesion of the paint film and clean the circuit board thoroughly,especially the soldering points.

4.Reason:Cracking caused by thermal stress due to rapid rise or fall of temperature.

Solution:Choose the conformal coating with good high and low temperature performance.

5.Cause:The paint film is not fully cured and does not reach the best performance.

Solution:Ensure sufficient curing time and temperature to ensure that the film is fully cured.

6.Reason:Paint film is too thick.

Solution:Reduce the film thickness or adjust the spray viscosity.

With the development of the electronic and electrical industry, electronic components are becoming more and more complex,and the requirements are getting higher and higher.The role of conformal coating has been affirmed by many PCBA factories.In addition,with the progress of science and technology, three-proof paint can improve the appearance of PCBA and PCBA energy efficiency, three-proof paint has been widely used in a variety of electrical appliances.