The controller PCB is the brain of electronic devices. It manages all operations and processes to ensure everything runs efficiently and smoothly. Without it, your device cannot perform its intended functions.

What is a controller PCB?

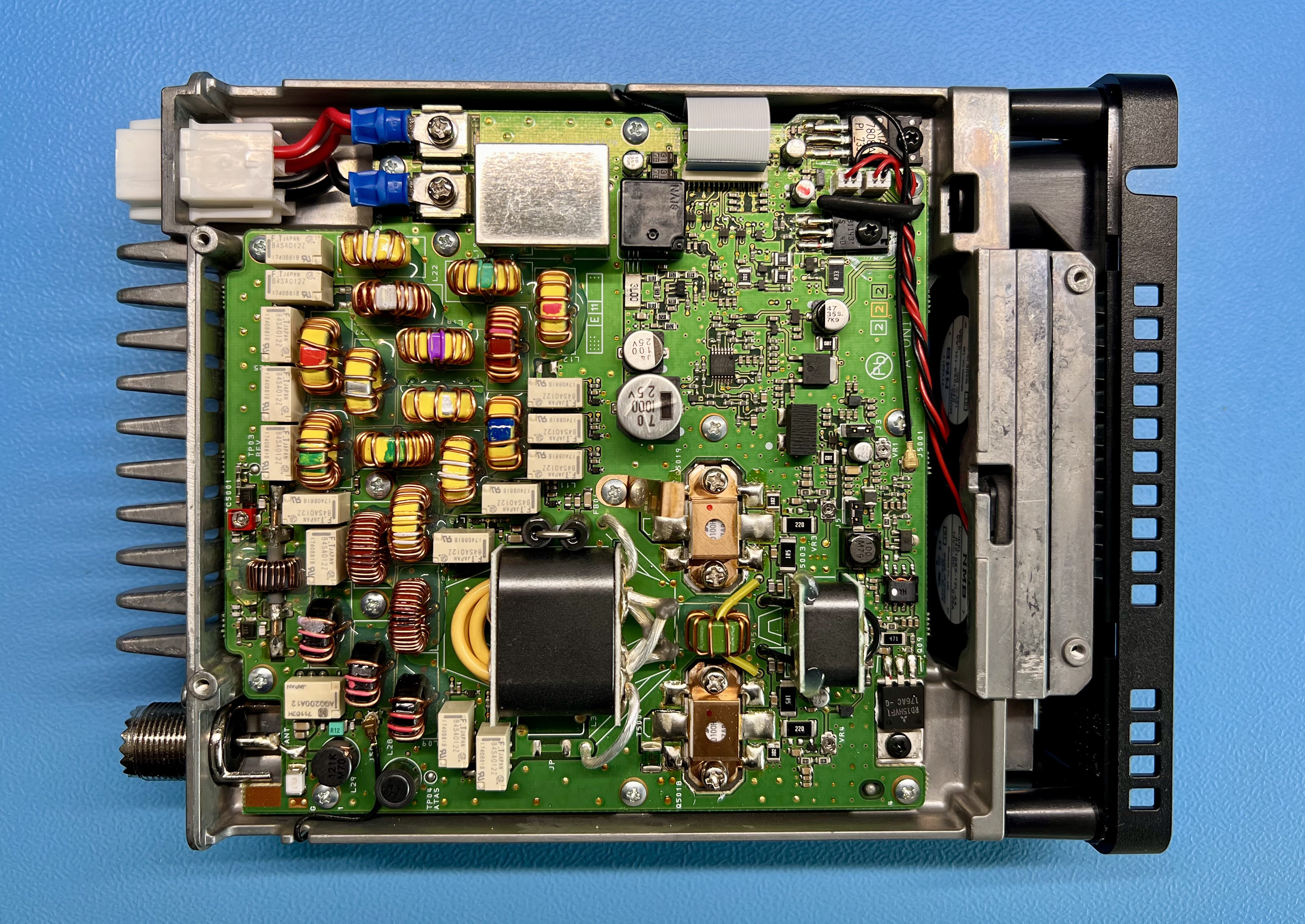

A controller PCB is a small yet powerful chip that coordinates the collaborative work of different components on a circuit board. It processes signals, controls power flow, and ensures data moves seamlessly between components. In short, it ensures the entire circuit board functions as intended.

It's easy to confuse a controller with a printed circuit board (PCB) itself, but they are not the same. The PCB is the physical board that houses and connects all electronic components. The controller, on the other hand, is just one part—responsible for telling others what to do.

These controllers are vital in today's technological landscape. They are found in devices like smartphones, automobiles, factory equipment, and medical machinery. Without a controller, a PCB is merely a collection of parts; with one, it becomes an intelligent system capable of responding, processing, and executing.

Types of PCB Controllers

Complex multilayer PCBs with multiple integrated circuits and components.

Not all controller PCBs are identical—they come in various types, each designed for specific tasks. Let's examine the most common controllers in modern electronic systems.

• Microcontrollers (MCU): These are small chips used for simple tasks in devices like microwaves, washing machines, or automotive systems. They are ideal for everyday electronics.

• Digital Signal Processors (DSP): DSPs handle rapid data processing in applications like audio systems, smartphones, or cameras. They process information in real time.

• Programmable Logic Controllers (PLC): PLCs are engineered for industrial use. They control factory machinery and are renowned for reliability and extensive input/output connections.

•Field-Programmable Gate Arrays (FPGA): FPGAs can be reprogrammed after manufacturing. This makes them valuable in robotics, aerospace, or prototypes that may change frequently.

• Application-Specific Integrated Circuits (ASIC): ASICs are customized chips designed for a single task. They are used in smartphones, gaming consoles, and other mass-produced products.

Applications of Controller PCBs

Controller PCBs are versatile and critical across industries. They play key roles in everyday devices and some of the most vital systems. Now, let's explore how these controllers are integrated and applied in different fields.

Consumer Electronics

PCBs are essential in consumer electronics. They manage data processing and power control. Commonly found in smartphones, tablets, and home appliances. Over time, demand for compact, efficient controllers has steadily increased.

Industrial Equipment

Controller PCBs in industrial equipment are engineered to handle demanding operations. They ensure seamless automation. These controllers are built to withstand harsh environments and complex tasks. It's essential to select controllers specifically designed for industrial-grade challenges, prioritizing reliability and durability.

Medical Devices

Precision is paramount in medical devices. Controller PCBs govern sensitive equipment and diagnostic tools. The accuracy and reliability of medical procedures depend on them. Therefore, controllers must pass stringent health and safety guidelines, as patients rely entirely on them.

Automotive Systems

Controller PCBs are critical to automotive system performance. This control spans automotive electronics, from engine management to infotainment. The controllers themselves must withstand extreme temperatures and endure vibration. However, for these designs to operate safely and efficiently on the road, they also require aerodynamic advancements. If controllers are selected, they must meet automotive standards.

Common Design Mistakes to Avoid

Wall-mounted PCB controller board with an additional digital display and various connectors

Even experienced designers may encounter issues when creating PCB controllers. Below are some common mistakes to watch out for and how to avoid them.

Overly Complex Layout: Adding extra features is tempting, but a cluttered layout can cause signal interference, make debugging difficult, and increase production costs. Keep your design clean and focused—simple often works best.

Poor thermal design: Controllers generate significant heat, especially in high-power applications. Without adequate heat dissipation, components may overheat and fail. Use vias, heat sinks, or proper component spacing to manage temperatures.

Poor power distribution: Unstable or uneven power supply can cause serious issues. Ensure your design incorporates robust power and ground planes, delivering power where needed without voltage drops or noise.

Incompatible component selection: Choosing the wrong integrated circuits, connectors, or voltage regulators can create bottlenecks or failure points. Always verify your parts match the power, scale, and communication requirements of your design.

Avoiding these pitfalls not only saves time and money but also delivers a more reliable and high-performance PCB controller.

Frequently Asked Questions (FAQ)

What distinguishes a PCB controller from a microcontroller?

A microcontroller is a type of controller PCB typically used in embedded systems. However, PCB controllers can also incorporate other types like PLCs, FPGAs, or ASICs, depending on the application.

What materials are best suited for PCB controllers?

Copper is the most common conductor material, while FR4 is a popular substrate choice. Gold and aluminum are also used based on design and environmental requirements.

Can controller PCBs be customized?

Yes, many controllers—especially FPGAs and ASICs—can be customized for specific functions. This enables greater control, higher efficiency, and application-specific performance.

How can EMI be reduced in controller PCB layouts?

Minimize electromagnetic interference (EMI) by employing shorter trace lengths, ground planes, and proper component placement. Simulation tools can help identify EMI issues early.

In summary, the design and manufacturing quality of a controller PCB directly determine the performance and reliability of the end product. We specialize in high-precision, high-stability controller PCB solutions and look forward to becoming your most trusted manufacturing partner for your next project.