Copper Clad Laminate (CCL), is a raw material for the electronics industry. The structure of CCL includes a substrate, copper foil, and CCL adhesive. It is a product made of wood pulp paper or glass fiber cloth as reinforcing material, impregnated with resin, covered with copper foil on one or both sides, and hot pressed. Copper-clad laminates can be made into circuit boards by engraving, hand-drawing, mapping, oil-printing, hot-melt plastic-film plate making, pre-coated photopolymerized copper-clad laminates, and thermal transfer printing.

The structure of the copper clad laminate

1.substrate: polymer synthetic resin and reinforcing materials composed of insulating laminates can be used as a substrate for copper-cladding board. There are many types of synthetic resins, commonly used phenolic resins, epoxy resins, PTFE and so on. Reinforcement materials generally have two kinds of paper and cloth, they determine the mechanical properties of the substrate, such as resistance to immersion welding, bending strength.

2.copper foil: it is the key material in the manufacture of copper-clad plate, must have high electrical conductivity and good weldability. Requirements for the surface of the copper foil shall not have scratches, trachoma and wrinkles, metal purity of not less than 99.8%, the thickness of the error is not greater than ± 5 um. In accordance with the provisions of the ministerial standard, the copper foil thickness of the nominal series for the 18, 25, 35, 70 and 105 um. Our country is now gradually promoting the use of 35 um thickness of copper foil. The thinner the copper foil, the easier it is to etch and drill holes, especially suitable for the manufacture of complex lines of high-density printed circuit board.

3.copper clad laminate adhesive: adhesive is the copper foil can be firmly covered in the substrate is an important factor. The peeling strength of copper clad laminates mainly depends on the performance of the adhesive.

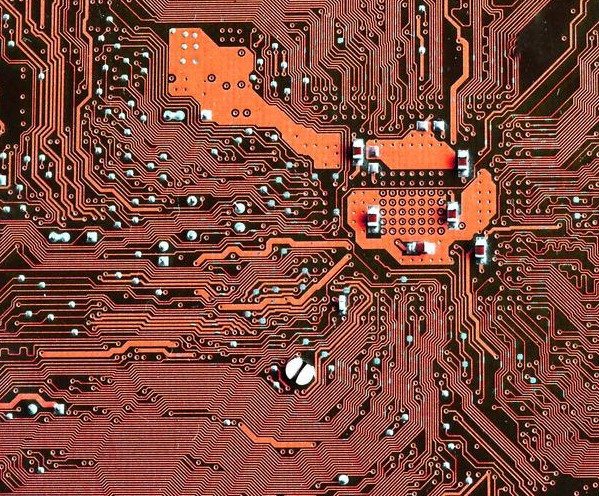

Copper Clad Laminate

PCB copper clad laminate classification

PCB copper clad laminate consists of three parts: copper foil, reinforcement material and adhesive. The boards are usually categorized by reinforcing material category and adhesive category or board properties.

Classification by reinforcing material

The most commonly used reinforcing materials for PCB copper clad laminates are alkali-free (alkali metal oxide content of not more than 0.5%) glass fiber products (such as glass cloth, glass felt) or paper (such as wood pulp paper, bleached wood pulp paper, cotton flannel paper), etc. The most commonly used reinforcing materials are alkali-free (alkali metal oxide content of not more than 0.5%) glass fiber products (such as glass cloth, glass felt) or paper (such as wood pulp paper, bleached wood pulp paper, cotton flannel paper). Therefore, PCB copper clad laminate can be divided into two categories: glass cloth-based and paper-based.

Classification according to the type of adhesive

The main adhesives used in PCB laminates are phenolic, epoxy, polyester, polyimide, polytetrafluoroethylene resin, etc. Therefore, PCB laminates are also divided into phenolic, epoxy, polyester, polyimide and polytetrafluoroethylene PCB laminates accordingly.

Classification according to the characteristics and use of the substrate

According to the substrate in the flame and leave the fire after the degree of combustion can be divided into general-purpose and self-extinguishing; according to the degree of substrate bending can be divided into rigid and flexible PCB cladding board; according to the substrate's operating temperature and working environment conditions can be divided into heat-resistant, radiation-resistant, high-frequency PCB cladding boards and so on. In addition, there are PCB laminates used in special occasions, such as prefabricated inner layer laminates, metal-based laminates, and according to the type of foil can be divided into copper foil, nickel foil, silver foil, aluminum foil, copper foil, beryllium copper foil laminates.

PCB Copper Clad Laminate Manufacturing Process

PCB copper clad laminate production process is as follows: resin synthesis and adhesive solution preparation - reinforcing material impregnation and drying - impregnation material shearing and inspection - impregnation material and copper foil lamination - hot press molding - cutting - inspection and packaging.

Synthesis and preparation of resin solution are carried out in the reactor. Most of the phenolic resins used for paper-based PCB laminates are synthesized by PCB laminates factories.

The production of glass cloth-based PCB laminating foil board is the raw material factory to provide epoxy resin and curing agent mixed with acetone or dimethyl formamide, glycol methyl ether dissolved, after stirring to make it a uniform resin solution. Resin solution after aging 8 ~ 24h can be used for dipping glue.

The dipping is carried out on the dipping machine. The dipping machine is divided into horizontal and vertical two kinds. Horizontal impregnation is mainly used for impregnation of paper, vertical impregnation machine is mainly used for impregnation of high strength glass cloth. Impregnated with resin liquid paper or glass cloth main, through the extrusion roller into the drying channel after drying, cut into a certain size, after passing the test ready for use.

Copper Clad Laminate (CCL), is the electronic fiberglass cloth or other reinforcing materials impregnated with resin, one side or both sides covered with copper foil and hot pressing and made of a plate material. A variety of different forms, different functions of the printed circuit board (PCB), are selectively processed on the copper clad laminate, etching, drilling and copper-plating processes, made of different printed circuits. Copper clad laminate on the printed circuit board is mainly interconnecting conduction, insulation and support of the role of the signal transmission speed, energy loss and characteristic impedance of the circuit has a great impact. Therefore, the performance, quality, manufacturing processability, manufacturing level, manufacturing cost and long-term reliability and stability of the printed circuit board depends largely on the copper clad board.