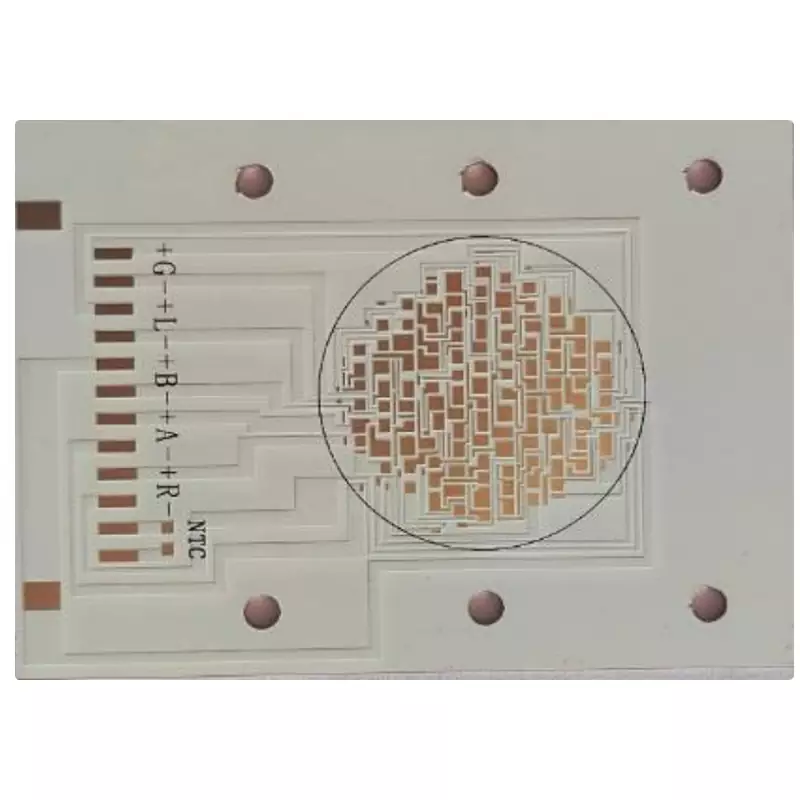

Product: Copper LED PCB

Material: copper

Layer: 1-2L

Color: White

Finished thickness: 1.2mm

Copper thickness: 2oz

Surface treatment: OSP

Minimum line width: 10mil

Minimum spacing: 10mil

Thermal conductivity: 3W/mK

Application: High power LED lamp

Copper PCB is the most expensive type of metal substrate, with thermal conductivity many times better than aluminum and iron-based substrates. Generally, there are gold-plated copper PCB, silver plated copper PCB, tin sprayed copper PCB, anti-oxidation copper PCB, etc.

Copper PCB circuit layers require a high current carrying capacity, therefore thicker copper foils should be used, typically ranging from 35 μ m to 280 μ m. The thermal insulation layer is the core technology of Copper PCB, which is composed of aluminum oxide and silicon powder, as well as polymer filled with epoxy resin. It has a low thermal resistance (0.15), excellent adhesive and elastic properties, and the ability to resist thermal aging, and can withstand mechanical and thermal stress. Copper PCB gold substrate is the supporting component of Copper PCB, which requires high thermal conductivity. It is generally made of copper plate, but copper plate can also be used (among which copper plate can provide better thermal conductivity), suitable for conventional mechanical processing such as drilling, punching and cutting.

Compared to ceramic substrates, ceramic substrates have better heat dissipation effects. Copper PCB has a high thermal conductivity of about 120W, and the heat dissipation capacity of ceramic substrates is between 15W and 170W. Ceramic substrates have better insulation properties.

The LED Copper PCB for car lights is mainly used for the production of metal circuit boards such as thermoelectric separation Copper PCB and copper aluminum composite board.

Copper PCB

Advantages of LED Copper PCB for Car Lights

1. The elastic modulus of copper is about 121000 MPa, and the corresponding warpage and shrinkage of copper PCB will be smaller, resulting in more stable overall performance.

2. Metal copper based materials can be etched into fine patterns by etching circuits, which can be processed into convex shapes that protrude to the wiring layer or surface mount level and are flush with the mounting surface. Components can be directly mounted on the convex shapes to achieve excellent grounding and heat dissipation effects.

3. Due to the inherent processing technology of Copper PCB, copper based materials can be processed into metalized holes, providing excellent optional grounding performance for corresponding single or multi-layer backplates. Additionally, copper itself has solderability, allowing for optional soldering during the final installation of designed structural components, resulting in much better heat dissipation effects than using heat sinks.

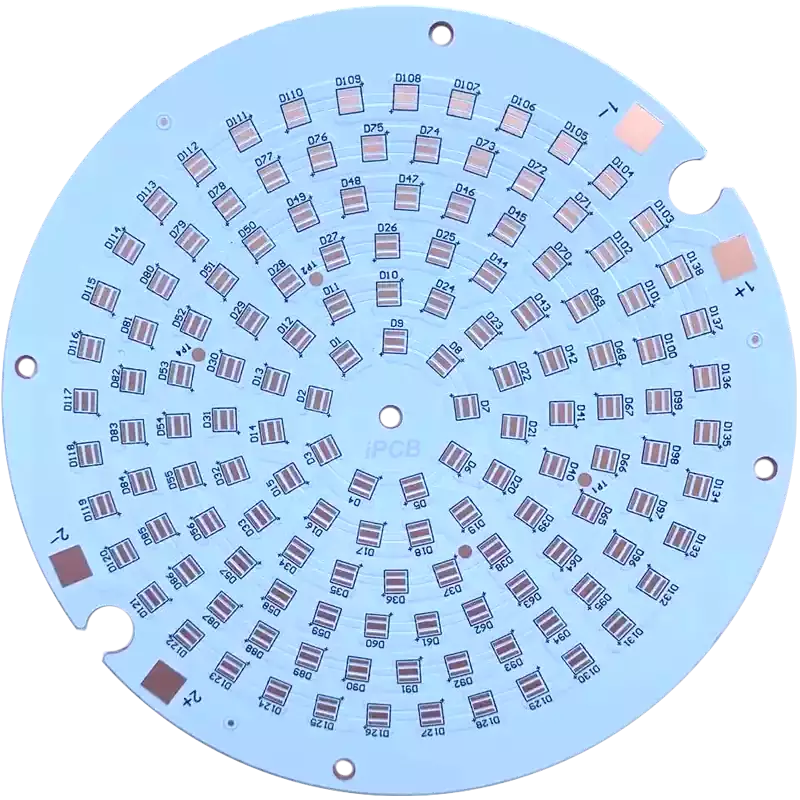

LED Copper PCB lighting refers to a type of lighting fixture manufactured using LED Copper PCB as the substrate. This type of lighting fixture utilizes circuits, LEDs, and other components on Copper PCB to achieve lighting functionality. LED Copper PCB is commonly used in LED lighting fixtures and has the characteristics of energy saving, high brightness, and thinness.

Product: Copper LED PCB

Material: copper

Layer: 1-2L

Color: White

Finished thickness: 1.2mm

Copper thickness: 2oz

Surface treatment: OSP

Minimum line width: 10mil

Minimum spacing: 10mil

Thermal conductivity: 3W/mK

Application: High power LED lamp

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.