Circuit card assembly (CCAs) are boards made of thin, flat insulating material covered with conductive wiring. In order to produce these assemblies efficiently, factories often use surface mount technology (SMT) and through-hole technology, which require specialised machines. The people who design and assemble these circuit cards must be very specialised and have extensive experience. Like common printed circuit boards (PCBs), circuit card assy is used in a wide range of household appliances such as TVs, laptops, microwave ovens, smartphones, smoke alarms and security cameras. Not only that, they also play an important role in several industries, such as navigation systems, power supply devices, automotive displays, medical imaging devices, and surveillance systems. Simply put, CCAs are an integral part of modern electronic devices that underpin many of the high-tech products we use in our daily lives.

The main types of circuit card assembly include surface mount technology (SMT) assemblies, complete assemblies, and through-hole assemblies.

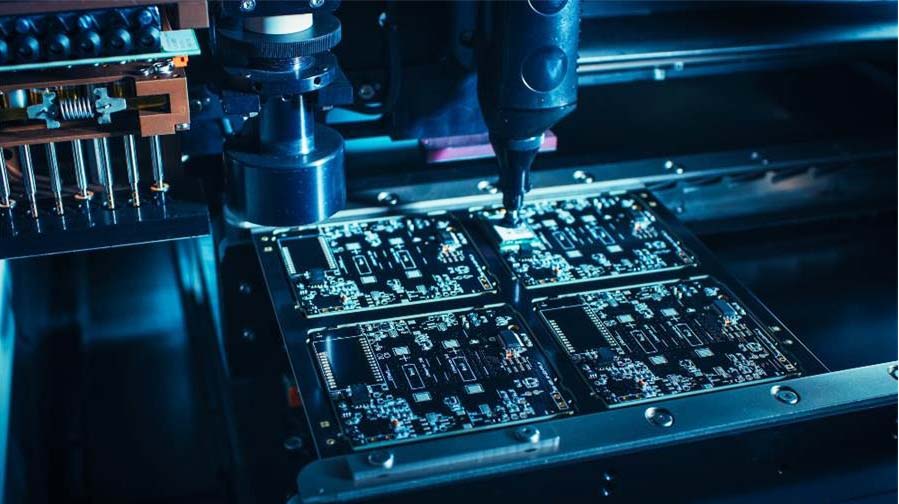

Surface mount technology (SMT) assembly is a time-honoured production technology that has been widely used in the manufacture of circuit card assy or printed circuit boards (PCBs) since the 1960's. SMT technology, with its flexibility and efficiency, has enabled modern electronics to be produced in smaller sizes. In this way, components with metal sheets can be successfully attached to the PCB. When the components are secured to both sides of the PCB using effective fastening techniques, a high-density layout of the circuitry is achieved.SMT technology is highly configurable and automated, making it ideal for manufacturers who need to produce circuit boards in large quantities. Although automated machines have a high initial investment cost, they can reduce the number of manual steps in an SMT operation, significantly increasing productivity and reducing labour costs over time. For needs that require customised circuit boards, SMT technology may be the best option. For example, surface mount devices (SMDs) such as microprocessors are permanently mounted using ball grid array (BGA) technology. BGAs are able to provide more connector pins than traditional two-row inline or flat packages, each equipped with a solder ball.

Complete assembly, also known as system integration, covers a wide range of components from simple circuit card assembly or PCBAs in small enclosures to complex electromechanical system cabinets. The process involves many aspects of design, production and construction, using tools such as looms, connecting assemblies, wire wheels, special metalwork and moulded plastics to assemble the electrical components onto the printed circuit board. In complete assembly, the enclosure must be designed, fabricated and installed along with PCBAs, cables, harness assemblies, and may even include electrical and/or pneumatic systems. This is the most widely used technology today, driving the hardware design and packaging industry towards greater modernity and stability. These robust and precise PCBs ensure accurate and efficient operation of electrical equipment.

Through-hole assembly is another circuit card assembly type in which the leads of electrical components are inserted into pre-drilled holes in the circuit board and then manually or automatically soldered to pads on the other side. As PCB design has evolved from single-sided to double-sided to multilayer boards, through-hole assembly technology has adapted to the needs of modern electronics. Although through-hole technology was popular between the 1950s and 1980s, SMT technology has largely replaced through-hole construction as surface mount PCBs have become more popular. However, in some applications, such as those involving electrolytic capacitors, connectors and large transformers, through-hole assembly is still the only viable option.

When performing circuit card assy, there are several key points that require special attention:

1. Component selection: Selection of appropriate components is fundamental to ensuring circuit performance. It must be ensured that the parameters of the selected components match the design requirements and are of reliable quality in order to avoid circuit failures caused by component problems.

2. Anti-static measures: Static electricity may cause damage to sensitive electronic components. Therefore, anti-static measures must be taken throughout the assembly process, such as wearing anti-static bracelets and using anti-static workbenches to protect components from static electricity.

3. Soldering temperature and time control: Soldering is the core step in circuit card assy. Soldering temperature and time must be strictly controlled to ensure the quality of the solder joints, to avoid damage to components or deformation of the circuit board due to excessive temperature or time.

4. Quality check and test: After the assembly is completed, a comprehensive quality check and test must be carried out to ensure that the circuit is correctly connected, firmly soldered, and there are no short circuits or broken circuits, etc. This is an important step to ensure the reliability of the product. This is an important step to ensure product reliability.

5. Welding process management: it is vital to establish a perfect welding process management system. This includes the development of standardised welding operation procedures, training of operators, regular maintenance of equipment, etc. to ensure consistency and high quality of the assembly process.

6. Layout design optimisation: In the circuit board design stage, the layout of components should be reasonably planned to ensure that the space is reasonably allocated to avoid interference or short circuits between components, thus enhancing the stability and reliability of the circuit.

As the core of modern electronic devices, the manufacturing and assembly process of circuit card assembly (CCA) requires sophisticated technology and strict quality control. From component selection to soldering processes, every aspect is critical. As technology advances, circuit card assy will continue to push the electronics industry forward, supporting smaller, faster, and smarter devices and becoming an important cornerstone of future technological innovation.