With the rapid development of wireless communication technology, RF systems are increasingly applied across various fields. However, while transmitting signals, RF systems also generate interference, which affects signal quality and transmission efficiency. To address this issue, microstrip bandstop filters on alumina ceramic substrates are widely used in RF systems to suppress unwanted interference.

The knowledge related to interference suppression in RF systems includes both theoretical knowledge and experimental research. The theoretical knowledge encompasses the design principles of filters, parameter calculations, and material selection. Experimental research includes performance evaluation methods such as impedance spectra, signal-to-noise ratio, and distortion.

Design Principles of Microstrip Filters and Coupled Circuits

Frequency Range: Typically between 1 MHz and 1 GHz. The specific frequency range depends on the filter’s design structure and the parameters of circuit components.

Bandstop Characteristics: Achieved by creating reactance coupling in a specific frequency band. The bandstop curve typically presents a symmetric bell shape, with high out-of-band suppression and low insertion loss.

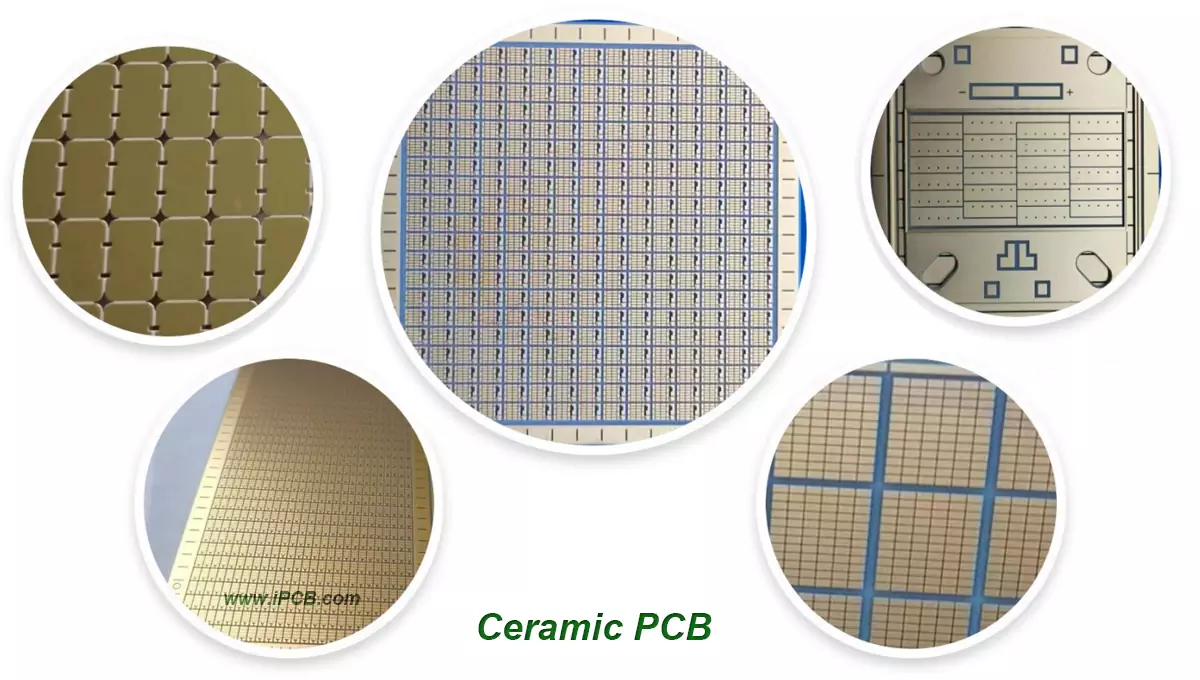

Manufacturing Process of Microstrip Bandstop Filters on Alumina Ceramic Substrates

Ceramic Substrate Manufacturing: The process of manufacturing alumina ceramic substrates involves ceramic powder preparation, pressing, sintering, and machining. The production of ceramic powder is a key step, requiring control over particle size and purity to ensure substrate performance.

Metal Circuit Manufacturing: The metal circuit is fabricated using techniques such as photolithography, sputtering, and evaporation. These processes require precise control over the circuit’s shape, size, and thickness to ensure filter performance.

Surface Treatment: The surface treatment of the filter includes coating or packaging, typically with polymer or metal materials. Surface treatment protects the filter from environmental factors, improving its corrosion and wear resistance.

Performance Evaluation of Microstrip Bandstop Filters

Impedance Spectrum: Measured using a network analyzer, typically represented by S-parameters (scattering parameters). By measuring the reflection and transmission coefficients of the filter at different frequencies, an impedance spectrum curve can be plotted to assess the matching performance of the filter at various frequencies.

Insertion Loss: An important indicator of filter performance, usually expressed as attenuation. The smaller the insertion loss, the lower the signal attenuation and the higher the transmission efficiency.

Signal-to-Noise Ratio (SNR): A key metric for evaluating the filter's ability to suppress noise, usually expressed as the ratio of signal strength to noise strength. The higher the SNR, the better the filter’s ability to suppress noise, leading to better signal quality.

Distortion: Evaluated using harmonic and intermodulation distortion, distortion measures the filter's linearity and stability. Lower distortion indicates better linearity and stability, resulting in higher output signal quality.

Application Prospects of Microstrip Bandstop Filters on Alumina Ceramic Substrates

Wireless Communication: Widely used in mobile phones and communication devices to suppress out-of-band interference and noise, improving communication quality and stability.

Aerospace: Used in navigation and radar systems to enhance the interference resistance and reliability of equipment, ensuring flight safety.

Military: Applied in electronic warfare and military radar systems to improve equipment security and combat capability, enhancing operational effectiveness.

Industrial Control: Deployed in robots and automation equipment to improve equipment stability and reliability, boosting production efficiency and quality.

Medical Equipment: Used in monitors and ultrasound machines to enhance equipment precision and stability, improving the accuracy and reliability of medical diagnoses.

As technology continues to advance and innovate, the application of microstrip bandstop filters on alumina ceramic substrates will continue to expand. Its design and manufacturing technology will be further optimized. In the future, with the continuous development and application of new materials, these filters may face new challenges and opportunities. However, as a key component in RF interference suppression, their application prospects remain very promising.

This article shares the design and manufacturing methods of microstrip bandstop filters on alumina ceramic substrates, covering design principles, manufacturing processes, performance evaluation, and application prospects. Microstrip bandstop filters have broad application prospects in RF interference suppression and are suitable for wireless communication, aerospace, military, industrial control, and medical equipment fields. Through continuous technological innovation and process improvement, it is expected that the performance and reliability of alumina ceramic filters will further improve, providing effective guarantees for the stable operation of RF systems.