PCB production, the process is an extremely important part, the general process is osp, gold immersion, gold plating, tin spraying, etc. Among them, tin spraying is the most common process in PCB production, which is not unfamiliar to everyone. Among them, tin spraying is the most common process in PCB production, which is not unfamiliar to all of us. In the tin spraying process, it is divided into ‘leaded’ and ‘lead-free’ two kinds.

What is tin spraying process in PCB surface process?

Tin spraying is one of the most common pipelines in PCB surface treatment, and the most commonly used process is tin spraying,also known as hot air levelling technology,which involves spraying a layer of tin on the pads to enhance the conductivity and solderability of the PCB pads.Tin spraying can be divided into lead-free tin spraying and leaded tin spraying.

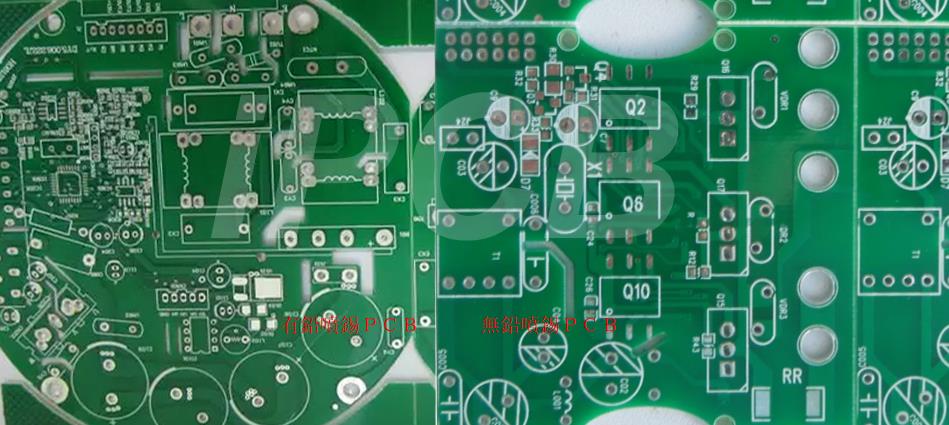

Lead-free tinned PCBs and leaded tinned PCBs

So what is lead-free tinning?What is leaded tinning?What is the difference between lead-free tin spraying and leaded tin spraying?

1.Lead-free tinning is an environmentally friendly process that does not contain the harmful substance ‘lead’ and has a melting point of about 218 degrees.The melting point is around 218 degrees Celsius.The temperature of the soldering furnace should be controlled at 280-300 degrees Celsius.The temperature of wave soldering should be controlled at about 260 degrees.Reflow soldering temperature is about 260-270 degrees.

2.Leaded soldering is not an environmentally friendly process,and contains the hazardous substance ‘lead’ with a melting point of 183 degrees.The temperature of tin furnace should be controlled at 245-260 degrees.Wave soldering temperature should be controlled at about 250 degrees.Reflow soldering temperature is about 245-255 degrees.

3.From the surface of the tin,leaded tin is brighter and unleaded tin is duller.The lubricity of lead-free tin is a little worse than that of leaded tin.

4.The lead content of unleaded tin does not exceed 0.5,while the lead content of leaded tin reaches 37.

5.The lead in leaded tin is harmful to the human body,while lead-free tin is not.The eutectic temperature of leaded tin is lower than that of lead-free tin.Specifically how much depends on the composition of lead-free alloy ah,like SNAGCU eutectic is 217 degrees,the welding temperature is eutectic temperature plus 30~50 degrees.It depends on the actual adjustment.Lead eutectic is 183 degrees.Mechanical strength.Brightness,etc.leaded is better than lead-free.

6.Lead will increase the activity of the wire in the soldering process,leaded wire is relatively better than lead-free wire.However, lead is toxic,long-term use is not good for the human body.Lead-free tin has a higher melting point than leaded tin,so the soldering point will be much stronger.

7.In surface treatment, the price of lead-free tinning and leaded tinning is usually the same,there is no difference.

What is the temperature difference between lead-free tinning PCB and leaded tinning PCB?

1.PCB lead-free tin spraying belongs to the environmental protection category and does not contain harmful substances ‘lead’, the melting point of about 218 degrees.Tin spraying furnace temperature needs to be controlled at 280-300 degrees.The temperature of the wave peak needs to be controlled at about 260 degrees.Reflow temperature 260-260 degrees.Reflow temperature 260-270 degrees.

2.PCB leaded tin spraying is not an environmentally friendly category containing hazardous substances ‘lead’, melting point of about 183 degrees.Tin spraying furnace temperature needs to be controlled at 245-260 degrees.The temperature of the wave peak needs to be controlled at about 250 degrees.Reflow temperature 245-25 degrees.Reflow temperature 245-255 degrees.

iPCB is a professional PCB manufacturer, specialising in double-sided.Multi-layer circuit board production.We can provide impedance boards, HDI boards, blind buried hole boards and other multi-layer PCBs.We can provide impedance boards, HDI boards, blind buried hole boards and other multi-layer PCB board sampling and mass production business.In consideration of environmental protection requirements, iPCB has eliminated the aluminium tin spray PCB, only lead-free tin spray PCB manufacturing process.The above is the PCB choice of lead-free tin spraying and leaded tin spraying what is the difference between the introduction, want to know more about PCB information and knowledge, you can pay attention to iPCB.