After the PCBA assembly is done,PCBA testing is required, generally there are two methods:manual testing and automated testing.So what is the difference between these two methods?

Manual testing and automated testing is not actually opposed to each other,not all the functions have to use automated testing.Automated testing has been developed for so many years, but it has not replaced manual testing. Automated testing is not very efficient, but it can be used to perform functionality regression in some scenarios.

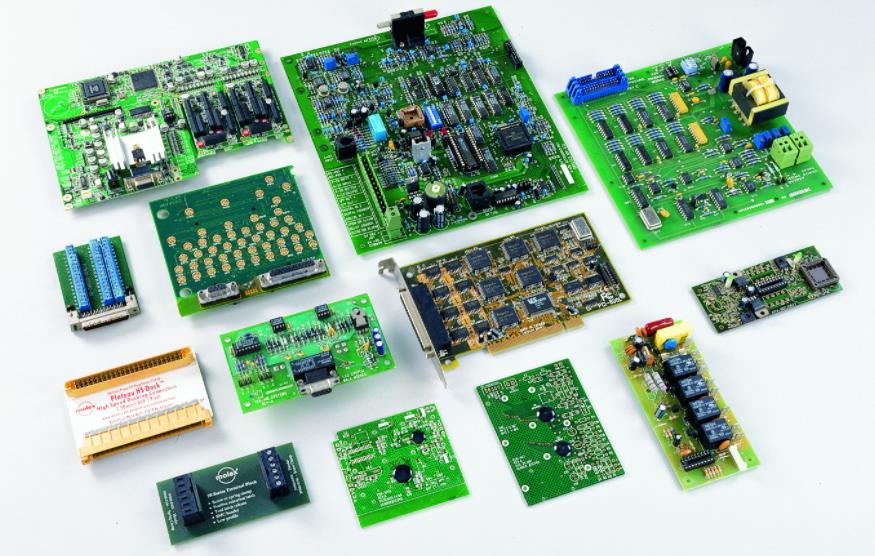

PCBA

1.Manual testing of PCBA features

Manual testing can be judged by human logic,verify the current steps are correct, while the execution of the use case has a certain step jump, can clearly know the logic, fine positioning problems.

If the time required to fix a bug is a little long,then it will be extremely difficult to apply manual testing to regression testing.This is because of the need to test too many use cases, so the need to introduce automated testing.

2.Automated testing of PCBA features

Execution of the object is a script, can be judged by the logic of man,verify that the current steps are correctly implemented,the use of the case of a strong correlation between steps,unlike the manual test cases so jumping. Automated testing is also used to ensure that the main function of the product is correct and complete, so that testers from the heavy work to get rid of.

PCBA automated testing can be performed at night. Testing has portability and repeatability,good test scripts often have a better platform portability, the software can be faster to market,automated testing saves a lot of time.

Conclusion: Manual testing and automated testing have their advantages and disadvantages.Automated testing has a long lead time, is costly and requires highly trained personnel.

Below is a comparison of ICT testing and test fixtures

ICT Testing | Test Fixture |

1: Test content: resistance / capacitance open short circuit, etc. | 1: Power on test working current and standby current More intuitive. |

2: Test single, can not measure the Hall switch function | 2:Implant the magnet on the fixture to achieve function detection (output high and low level 5V-0V). |

3: Optimised testing speed | 3: Comprehensive testing, high yield rate. |

4: Can not achieve the intended test results, the subsequent assembly will have to test the functions | 4: Test fixtures equipped with docking collection module + computer software, fixtures analogous to the finished product function test, one-step can be used directly. |

Comparatively,in this case,the ICT integrated assessment does not have an advantage.The advantage of ICT is that it is fast.The disadvantage is to test the resistance value,capacitance value and so on,test a single,especially today, technology is more and more advanced,integrated circuit is getting higher and higher,ICT has a lot of things can not be tested, only through the function test to solve. (If you must ICT test,our company can also cooperate).

The test rack is a function test, relative test speed is a little slower, but the through rate of the big goods to the customer will certainly be much higher than the ICT test. According to the order of communication, test rack test can fully meet the needs of large-volume PCBA testing,project demand for new, our company can also open more than one test rack to match the production,test rack on the PCBA functional testing advantages: product testing, delivered to the customer can be used directly, the functional test is more comprehensive, the delivery of good throughput rate is high, and quality control is better.Comic books are recommended to use PCBA test racks to test.