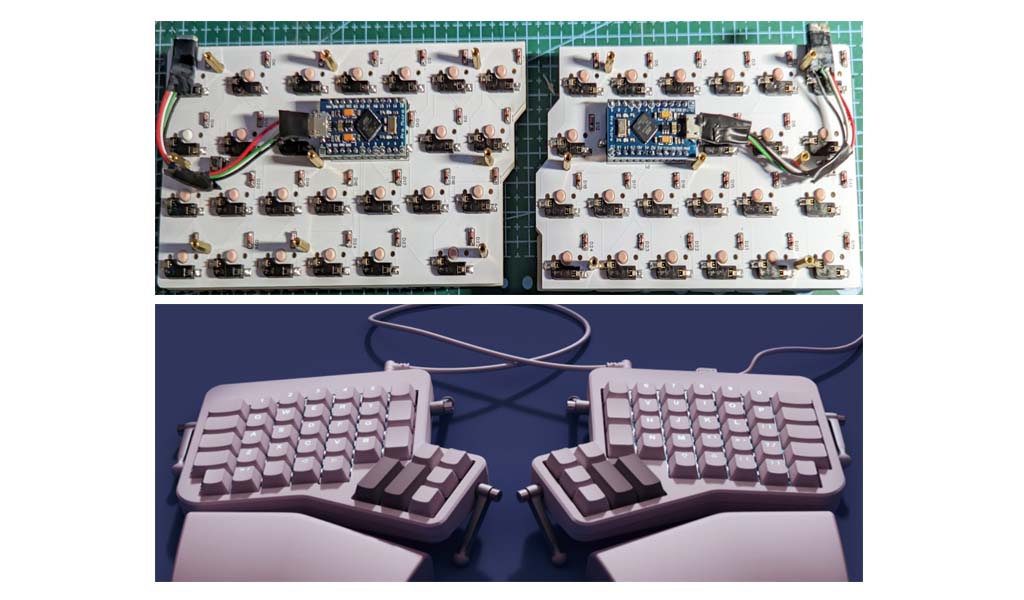

Split Keyboard PCB refers to the Printed Circuit Board of the split keyboard. This is a flat plate with integrated circuits and electronic components, which is responsible for receiving and transmitting signals from the keys. It is usually composed of multiple layers of materials, including conductive paths, insulating layers, and necessary electronic components. This circuit board plays a vital role in electronic devices, especially in input devices such as keyboards, ensuring that the operation of the keys can be accurately converted into electrical signals, so as to achieve the corresponding functions. This keyboard divides the traditional keyboard into two independent parts, each with its own PCB. Split Keyboard PCB users can adjust the relative position of the two parts as needed to achieve a more ergonomic keyboard layout.

The specific difficulties in making split keyboard pcb include:

1.Design complexity: The production of this circuit board needs to take into account multiple aspects such as key layout, wiring method, and lighting control, so the design needs to consider the connection and layout between different functional modules. The split design also needs to consider the power distribution and management of the two parts.

2.Small batch production: customized demand, since split keyboards are usually produced in small batches, the customization demand is high and the manufacturing cost is high. Production inconsistency, small batch production may lead to production inconsistency, affecting quality control.

3.Cost control: Since split keyboard pcbs usually require special shapes or multi-layer designs, costs may increase during the production process, and there are corresponding requirements for raw materials and equipment.

4.Processing technology: In actual production, there are certain requirements for drilling, welding and other processing technologies required for split keyboard printed circuit boards, which also increases the difficulty of production.

In general, the difficulty of making split keyboard printed circuit boards is mainly reflected in the requirements for accuracy, material selection and complex production processes, and certain electronic technology and fine operation capabilities are required to successfully complete them.

The production of split keyboard PCBs involves multiple links from demand analysis, design, manufacturing to testing, and each link requires fine design and strict quality control. Although the production process is complicated, through reasonable design and process flow, high-quality split keyboards can be produced to provide users with a more comfortable and personalized experience.

Advantages of Split Keyboards:

1.Ergonomic Design:

Reduces stress on wrists and shoulders: The split design allows users to adjust the placement of the keyboard according to their comfort, reducing the stress on wrists and shoulders from long-term typing.

Natural Arm Posture: Users can place the two parts of the keyboard wider to maintain a natural arm posture and reduce tension in the arms and shoulders.

2.Customizability:

Customizable layout: Users can design and use different keyboard layouts according to their needs.

Replaceable keycaps and switches: Many split keyboards allow different keycaps and switches to be replaced to suit different hand feels and typing habits.

3.Portability:

Easier to carry: The split design makes the keyboard easier to split and store, making it easier to carry and store.

4.Versatility:

Modular design: Some split keyboards support modular expansion, and additional functional modules can be added, such as a trackpad or additional macro keys.

Split Keyboard PCB is a well-designed and adaptable keyboard type, especially for users who value ergonomics and personalized needs. Despite their higher cost and some acclimation time, their comfort and customization advantages over extended use make them popular in the professional and enthusiast markets.