Dk is the dielectric constant denoted by ε r and Df is the loss factor denoted by Tan δ. There are many different test methods for determining the Dk and Df of a circuit material. For example, IPC has 12 test methods for determining the Dk of a material, and industry organisations, universities or companies also have their own test methods.

One book on microwave material characterisation describes more than 80 test methods for evaluating the Dk and Df of a circuit material.In the final analysis, no test method is perfect and electronic engineers should use the test method that best represents the circuit form of their product.Now we will explain the test methods for Dk and Df of circuit board PCB materials, and introduce some common test methods for determining Dk and Df.

Material Test Methods

The methods for testing the materials of high frequency circuits can be divided into two main categories: raw material-based test methods and circuit-based test methods. Raw material-based test methods typically use fixtures to evaluate dielectric raw material properties. This type of test method only evaluates the characteristics of the raw material and does not include circuit processing variables. Circuit-based test methods utilise a circuit carrier and select from Dk (and sometimes Df) depending on the circuit performance being tested. Since the accuracy of the material-based test method depends on fixture variables and the circuit-based test method depends on circuit processing variables, the Dk/Df values obtained by these two different types of test methods may not be the same.

the test method will yield Dk/Df values for different orientations of the material depending on the orientation of the electric field. Some test methods test Dk/Df values in the Z-axis (thickness axis), while others test Dk/Df values in the X-Y plane. Most circuit materials used in the PCB industry are anisotropic, i.e. the Dk/Df is different in each direction dimension. As a result, if a sample of the same material is tested using two different test methods, different Dk values may be obtained, but both values will be correct. If the material is anisotropic, one method evaluates the Dk value in the Z-axis of the material and the other evaluates the Dk value in the X-Y plane when testing the same material, so the two different test methods will yield different Dk values.

Other factors that need to be taken into account in the test method include material dispersion, surface roughness of the copper foil and the use of transmission/reflection technology. All materials have dispersion, which means that Dk will vary with frequency. This means that if the same test method is used for the same material, but at a different frequency, the Dk value will vary. In general, as the frequency increases, the Dk value decreases slightly.

Regardless of the Dk value of the original dielectric material, the surface roughness of the copper foil will slow down the propagation of the signal wave. A slower propagation rate of the signal through the dielectric can be considered as a higher Dk value for the dielectric. Some test methods are sensitive to copper foil surface roughness, while some are not.

Finally, it is generally recognised that test methods using resonance are generally more accurate than those using transmission/reflection. The resonance test method is generally more accurate, but can usually only test Dk results at one or more discrete frequencies. The transmitted/reflected method gives the variation of Dk with frequency over a wide frequency band.

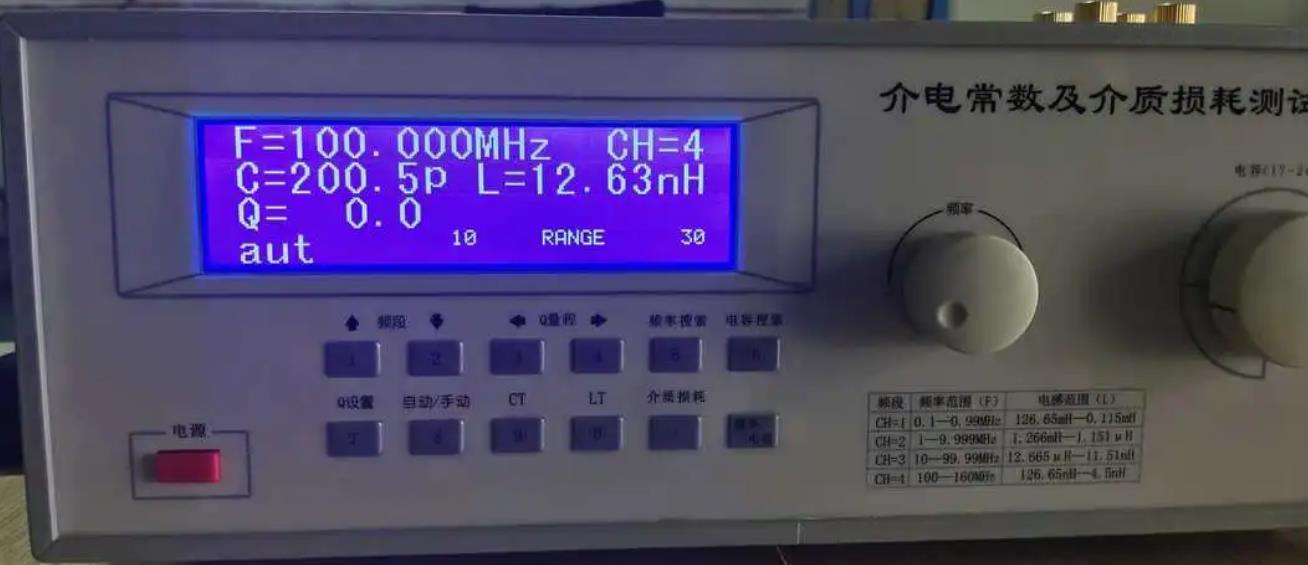

Commonly used DK dielectric tester

What are some common DK/DF test methods used in the PCB industry?

1, IPC-TM-650 2.5.5.5c defined X-band clamped ribbon resonator test method

After the laminate is produced, the copper foil is etched off and only the dielectric material sample is placed into a fixture for testing. The fixture has a very thin resonator plate in the centre, with a ground plane on either side of the plate. The material under test (MUT) is placed between the resonator plate and the ground plane. When the fixtures are clamped together by pressure, the fixtures and the material under test form a ground-signal-ground band RF structure, more specifically a ground-MUT-signal-MUT-ground structure. This test method evaluates the Dk and Df of the Z-axis of the material at a number of discrete frequency points starting at 2.5 GHz and ending at about 12.5 GHz. Typically, however, the test method only evaluates relatively more precise frequency points at 10 GHz.

One drawback of the test method is that the measured Dk value is sometimes slightly lower than the Dk value of the material due to the problem of trapped air inside the fixture (air has a Dk value of about 1). Another concern is that when the tested material is highly anisotropic (Dk is not the same in all 3 axes), the resonance peaks may change, thus reducing the accuracy of the measured Dk. This is often not a cause for concern unless some materials have a high nominal Dk value (e.g. Dk greater than 6). Materials with lower nominal Dk values are usually less anisotropic. Overall, this is an excellent high-volume test method for circuit material manufacturers to use for Dk/Df testing to ensure consistent Dk/Df performance of their materials.

2. Split Cylindrical Resonator Test Method Defined in IPC-TM-650 2.5.5.13

This test method is for a cylindrical resonator, which, as the name implies, is split and can be turned on and off. After the laminate has been produced, all copper foils are removed by etching, and the material under test (MUT) is placed between the split cylindrical resonators and switched off for testing. The resonator has a number of different resonance peaks that the user can choose from to evaluate Dk and Df, but these different resonance peaks have different frequencies. The test method evaluates Dk/Df in the X-Y plane of the material, not in the Z-axis direction. In addition, the test method can also be used with the clamped strip line test method (Z-axis method) to measure Dk/Df at the same frequency, so if the same material is evaluated using these two test methods, the comparison of the respective data can be used to get the anisotropic properties of the MUT of the material under test. It is worth noting that if the material is anisotropic, the same material tested with a clamped strip line will have a different Dk value than a split cylindrical resonator.

3. Microstrip Ring Resonator Test Methods

This is a circuit-based test method where the ring resonator circuit is designed to act as a test carrier on the material to be evaluated. The ring resonator is usually coupled to the ring resonator circuit (the ring looks like a very narrow ring) by means of an open-circuit 50 Ω transmission line acting as a feed line to couple the RF signal to the resonator circuit. The gap between the two feed lines and the toroidal resonator is critical, and variations in the gap area can cause Dk to be selected incorrectly. In addition, if the completed circuit resonating with the ring has a thicker copper plating than a ring resonator circuit of the same design on the exact same material but with a thinner layer of copper, then the gap area of the thicker plated circuit will have more electric field in the air, causing the resonance peaks to be shifted. Due to the difference in copper plating, the Dk values of the selected circuits will be different, and the Dk values of the evaluated materials will be inaccurate. Variations in coupling gap and copper thickness are normal circuit processing variables, and testing based on this resonant loop circuit will have to include this, but most material testing does not have this variable. The thickness of the copper plating is a natural and inherent variable in the PCB Board, and when using the ring resonator method, this difference in thickness can lead to inaccurate results in the Dk test. Assuming that the engineer understands the copper thickness issue and how it affects the Dk selection process, these variables can be eliminated to find the correct Dk value for the material. In addition, this test method is also affected by the surface roughness of the copper foil, whereas the first two tests are not affected by roughness. The Ring Resonator evaluates the Dk value of a material in the Z-axis direction.

It is important for electronic design engineers to understand the differences between methods of testing materials, especially when comparing Dk and Df values in material tables. If a particular DK/DF value is already in the data book, it is important to note the test method used. Ideally, it is best to compare DK/DF data using the same test method and the same frequency. When this is not always possible, it is good to compare DK/DF data at approximately the same frequency when different test methods are used to evaluate DK in the Z-axis direction.

More importantly, when an electronic engineer is comparing material tables or evaluating material DK/DF characteristics for use in a new design, it is recommended that the material manufacturer be consulted to understand the DK and DF test methods that were used to obtain the critical data in the material tables.