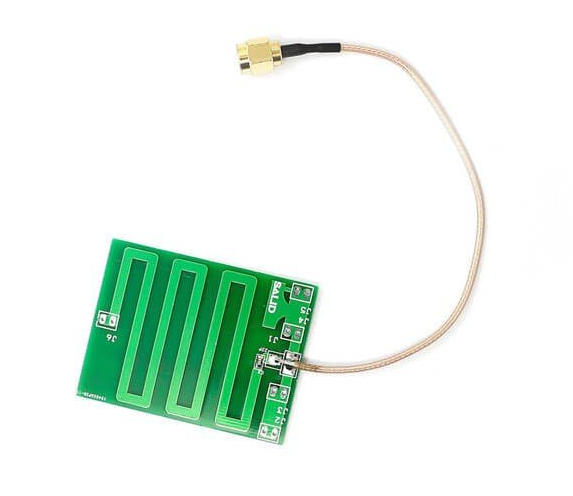

Product Name: Drone Antenna

Substrate: High TG FR4

Layer Count: 4-16 layers

Finished Thickness: 1.6mm

Copper Thickness: 1mil

Minimum Line Width/Spacing: 0.5mm/0.5mm

Surface Finish: Immersion Gold

Minimum Mechanical Hole Diameter: 0.3mm

Laser Blind Hole: 0.1mm

Product Applications: Power line inspection, communication equipment

The drone antenna is a critical component within the unmanned aerial vehicle (UAV) system, enabling wireless communication. Its primary function is to convert electrical signals between the UAV and ground stations (such as remote controllers) into electromagnetic waves for transmission, whilst simultaneously receiving control signals and data transmitted from ground stations.

Why is the antenna so crucial?

UAV flight relies on two fundamental data streams: uplink control commands (from the remote controller to the UAV) and downlink image data (from the UAV to the ground station). Interruption in either stream carries severe consequences: disrupted control commands risk uncontrolled crashes, while halted image transmission renders flight effectively blind, negating the UAV's practical utility.

As the gateway of the wireless communication system, the drone antenna manages the reception and transmission of electromagnetic waves. Its performance directly influences signal strength, transmission range, and interference resistance. A superior antenna maintains stable connections in complex environments, whereas substandard antennas may cause signal instability even under ideal conditions.

How does antenna technology safeguard this ‘life-or-death line’?

1. Polarisation Methods: Adapting to Drone Attitude Changes

Drones exhibit dynamic flight postures, frequently tilting or rotating. Conventional linear polarised antennas suffer significant signal attenuation in such environments. Modern drone antennas predominantly employ circular polarisation, enabling signals to propagate in a helical pattern. This ensures stable connectivity regardless of the drone's changing orientation.

2. Multi-Antenna Systems: Redundancy for Reliability

Advanced drones typically feature multiple antenna arrays configured as MIMO (Multiple-Input Multiple-Output) systems. This design not only enhances data transmission rates but also significantly improves connection reliability through diversity reception techniques. Should one antenna group encounter signal obstruction, the system automatically switches to antennas with superior reception, ensuring uninterrupted connectivity.

3. Intelligent Beamforming: Precision Directional Transmission

Certain high-end antennas support beamforming technology, dynamically adjusting radiation patterns to concentrate signal energy towards the drone's direction. This approach resembles focusing a torch beam rather than using a bulb for omnidirectional illumination, greatly enhancing transmission efficiency and interference resistance.

4. Band Compatibility: Comprehensive Coverage Requirements

Modern drones must handle communications across multiple bands simultaneously: 2.4GHz and 5.8GHz for remote control and video transmission, alongside the 1.5GHz band for satellite navigation. Superior antenna design accommodates all essential bands within limited space, fulfilling all-round communication needs.

Key Parameters for Drone Antenna Design

Frequency Range

Common bands: 433MHz (long-range data transmission), 900MHz, 2.4GHz (remote control), 5.8GHz (video transmission).

Must match the frequency bands of the remote controller and video transmission module.

Gain

Higher gain enhances signal directionality but reduces coverage angle. A balance between gain and coverage area is required.

Polarisation

Linear polarisation (vertical/horizontal) or circular polarisation (left-hand/right-hand). Circular polarisation reduces multipath interference, making it suitable for complex environments.

Dimensions and Weight

Miniaturised designs (e.g., patch antennas, flexible PCB antennas) to accommodate UAV weight reduction requirements.

Environmental Adaptability

Waterproof, dustproof, and vibration-resistant designs for harsh conditions (e.g., agricultural spraying, search-and-rescue missions).

Common PCB Materials for Drone Antennas

Materials must balance high-frequency signal transmission, mechanical strength, and cost. Common types include:

Rogers Materials

Characteristics: Wide dielectric constant range (2.2–10), low loss, suitable for high-frequency millimetre-wave antennas (e.g., 24GHz UAV altimetry antennas). Common grades like RO4350B (dielectric constant 3.66, loss 0.004) are frequently employed in UAV millimetre-wave radar antenna designs.

Application scenarios: Millimetre-wave and satellite communications requiring high signal quality.

Polytetrafluoroethylene (PTFE) laminates

Characteristics: Stable dielectric constant (2.0–3.0), extremely low loss, excellent high-frequency performance, but relatively high cost.

Application scenarios: High-precision radar antennas, aerospace applications.

Ceramic-filled laminates

Characteristics: Dielectric constant adjustable by modifying ceramic content; high mechanical strength and thermal resistance; balanced performance and cost.

Applications: 5G communication antennas, miniaturised high-frequency antennas.

FR-4 laminates

Characteristics: Low cost; good mechanical strength and insulation properties; dielectric constant 4.0–4.5.

Applications: Suitable for short-range communication antennas with modest performance requirements (e.g., Bluetooth, Wi-Fi).

Drone antennas find extensive application across military, civil, and commercial domains. In military operations, they support reconnaissance, surveillance, target acquisition, and communication relay missions. Civilian applications include aerial photography, environmental monitoring, and traffic patrols. In commercial applications, they support logistics delivery, agricultural crop protection, and power line inspection.

As drone technology continues to advance, antennae will encounter both greater challenges and opportunities. Future developments will prioritise enhanced performance, lighter weight, and greater intelligence. Concurrently, the rollout of next-generation communication technologies like 5G and 6G will unlock further innovation and growth potential for drone antennae.

Product Name: Drone Antenna

Substrate: High TG FR4

Layer Count: 4-16 layers

Finished Thickness: 1.6mm

Copper Thickness: 1mil

Minimum Line Width/Spacing: 0.5mm/0.5mm

Surface Finish: Immersion Gold

Minimum Mechanical Hole Diameter: 0.3mm

Laser Blind Hole: 0.1mm

Product Applications: Power line inspection, communication equipment

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.