A drone PCB board, simply put, is the circuitry inside a drone used to carry and connect various electronic components. It is responsible for signal transmission, power distribution, and the integration of functional modules, forming the foundation for core components such as flight control systems, image transmission modules, ESCs, and power management. Unlike circuit boards in ordinary consumer electronics, drone pcb boards typically operate in high-frequency, high-temperature, and high-vibration environments, thus requiring more stringent design, material selection, and manufacturing processes. With the widespread application of drones in various fields, their electronic systems are becoming increasingly complex. As the core carrier, the PCB board directly affects the drone's control accuracy, weight, anti-interference capabilities, and endurance.

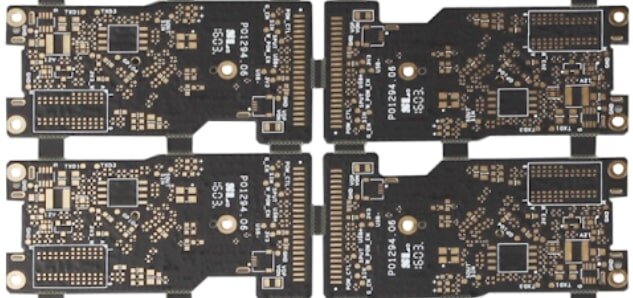

drone pcb board

Drone pcb board Manufacturing Process

Drone PCBs are mostly mid-to-high-end multilayer boards, commonly with 4-12 layers, and some industrial or military drones even reaching 16 layers or more. Key control points during manufacturing:

Material Selection

The selection of materials for the PCB board is crucial, requiring consideration of requirements such as high-temperature resistance, corrosion resistance, and lightweight design. Commonly used PCB materials include copper-based substrates, insulating substrates, and copper-clad laminates. Choosing appropriate materials ensures the stability and reliability of the PCB board in harsh environments. Materials used include FR-4 (glass fiber epoxy)/high TG FR-4/Rogers/Taconic/aluminum substrate/PTFE. High-end drones typically employ multi-layer hybrid structures (such as FR-4 + PTFE) to balance cost, mechanical strength, and signal performance.

Precision Machining: The machining accuracy of PCB circuit boards directly affects their performance and quality. Precision machining technology, using high-precision CNC machine tools and laser processing equipment, ensures the dimensional accuracy and surface flatness of PCB circuit boards. This helps improve the electrical performance and reliability of the PCB circuit boards.

Surface Treatment: Surface treatment of PCB circuit boards is key to improving their wear resistance and corrosion resistance. Common surface treatment methods include electroplating, spraying, and coating. These methods enhance the surface hardness and corrosion resistance of PCB circuit boards, extending their service life.

Testing and Inspection: Rigorous testing and inspection processes are necessary to ensure the quality and performance of PCB circuit boards. For the sample stage, a rapid prototyping + small-batch trial production approach is generally used to verify the design rationality and actual performance. Testing and inspection include electrical performance testing, mechanical performance testing, and environmental adaptability testing. These tests comprehensively evaluate the performance and reliability of PCB circuit boards, ensuring they meet design and usage requirements.

UAV HDI (High-Density Interconnect) circuit boards are high-end printed circuit boards used in drones, offering the following characteristics and advantages:

HDI boards employ a multi-layer structure design, achieving higher wiring density and functional integration within a limited space. Simultaneously, the use of thin materials not only effectively reduces overall weight but also enhances the drone's maneuverability and endurance, which is particularly crucial for long-endurance or special mission drones.

Small apertures and fine wiring ensure efficient signal transmission: HDI boards feature small apertures and precise wiring capabilities, allowing more components and signal lines to be accommodated within a limited area, achieving higher integration. Their extremely small line width and spacing significantly reduce signal delay and attenuation, improving circuit transmission speed and stability, thereby meeting the high-performance requirements of drones in flight control and data processing.

HDI pcb

UAV PCB Industry Trends

Currently, the global drone market is in a phase of rapid development. According to market research reports, the global drone market is projected to reach several billion US dollars by 2025. This growth trend will undoubtedly provide a significant boost to the drone circuit board market. The demand for high-performance circuit boards is particularly strong in fields such as military, security, and agriculture.

With technological advancements, drone pcb boards will integrate more functions to improve performance, while reducing weight through the use of lightweight materials and optimized design. In terms of reliability, more advanced materials and processes will be adopted to cope with extreme environments, and in terms of intelligence and environmental protection, PCBs will develop towards higher automation and lower pollution.

Choosing a Reliable drone pcb board Manufacturing Partner

For drone R&D companies, a reliable PCB partner is crucial.

An ideal supplier should possess:

Experience in multilayer, high-frequency, and high-precision PCB production

Rapid prototyping capabilities (24-48 hours)

A traceable quality management system

Understanding of drone project requirements (such as lightweight and electromagnetic compatibility design)

iPCB's long-term clients include numerous drone OEMs and flight control system solution providers. From sample prototyping and engineering optimization to small-batch pilot production and mass production conversion, we provide our clients with one-stop PCB solutions. We offer the most affordable prices for high-quality PCBs made with cutting-edge materials. We manufacture the products you prefer based on the specifications in your drone pcb board Gerber file. We can complete any PCB type, regardless of size.

The performance of a drone depends not only on flight control algorithms and motor efficiency, but also on the "invisible core"—those stable and reliable circuit boards. Excellent PCB design and manufacturing are the fundamental guarantee for stable drone flight in complex environments. Whether you are developing a consumer-grade aerial photography drone, an agricultural plant protection drone, or an industrial inspection drone, choosing a partner with technical expertise and a commitment to quality is always a crucial step towards drone pcb board project success.