Like other electrical interconnects, flexible FPC boards are susceptible to electromagnetic (EM) and radio frequency (RF) interference. The negative consequences of EM and RF interference range from increased error rates to complete data loss. To address this interference problem in FPCs, EMI shielding is achieved using copper layers, silver ink, and specialized shielding films.

Interference has two meanings: the performance degradation of equipment after being interfered with, and the source of interference that causes the interference. The first meaning includes examples such as lightning causing static on a radio, snow on a television screen after a motorcycle passes nearby, or hearing radio noise after picking up a phone. These can be abbreviated as I (interference) in abbreviations like BC, ITV, ITeel, and I (BC: broadcast). So, what part of EMI does EMI standard and EMI testing cover? It naturally refers to the second meaning, the interference source, which also includes the electromagnetic energy before interference occurs. EMI significantly reduces the performance of a circuit board, even causing it to stop operating. At high frequencies, interconnects often act as antennas and emit radiation. This EMI radiation can interfere with other nearby components, affecting the performance of the circuit board. Therefore, measuring and controlling electromagnetic radiation is crucial.

What are EMI and RF shielding?

EMI and RF shielding is a method used to prevent electromagnetic and radio frequency interference from external signals. It also suppresses high-frequency signal leakage and interference with surrounding circuits. This is achieved by using a metal barrier to absorb electromagnetic interference propagating through the air. The shielding effect is based on the principle used in Faraday cages, where a metal screen completely surrounds sensitive or emitting electronic devices. A Faraday cage is a cage made of metal or a good conductor. Named after Michael Faraday, the British physicist who founded electromagnetism, it is a device used to demonstrate the principles of equipotentiality, electrostatic shielding, and high-voltage live-line work. It consists of a cage, a high-voltage power supply, a voltage display, and a control unit. The cage is connected to the ground. The high-voltage power supply delivers 100,000 volts DC to a discharge rod through a current-limiting resistor. When the tip of the discharge rod is 10 centimeters from the cage, a discharge spark occurs. According to the condition of electrostatic equilibrium of a grounded conductor, the cage is an equipotential body with zero internal potential difference and zero electric field. The charge is distributed on the outer surface near the discharge rod.

A Faraday cage is a metal enclosure that prevents electromagnetic fields (EM fields) from entering or escaping. An ideal Faraday cage consists of an unbroken, perfectly conductive layer. This ideal state is unattainable in reality, but can be achieved by using a fine-mesh copper screen. For optimal performance, the Faraday cage should be directly grounded.

Flexible FPC Shielding Design Challenges

When considering EMI shielding for flexible FPC boards, you will encounter a variety of design challenges. All shielding methods will increase the thickness and cost of the flexible FPC circuit to some extent. The most common difficulty is the increased thickness, leading to bending difficulties and larger bending angles. This raises concerns about mechanical failure and reliability. The additional cost can be substantial. In addition, the number of layers in the design will increase.

When choosing the type of EMI shielding for a flexible FPC, it is necessary to consider bending requirements and controlled impedance.

1. Bending Requirements

Each shielding method will affect the total thickness of the flexible FPC circuit. Since the minimum bending capability is a function of thickness, it will limit or reduce the bending capability of the flexible FPC. As part of the design and material selection process, the minimum bending radius and bending type requirements for the shielding design must be precisely determined and evaluated.

The required bending type, whether static or dynamic, imposes additional constraints. Dynamic flexible FPCs have significantly greater bending capabilities than statically bent designs.

2. Controlled Impedance EMI and RF shielding methods are further constrained by the controlled impedance signal requirements in flexible FPCs. The shielding layer must possess electrical characteristics that simultaneously meet EMI and reference plane standards to achieve an appropriate regulated impedance value. Not all shielding techniques meet both requirements.

EMI shielding for flexible FPCs uses three types of materials: copper layers, silver paste, and specialized shielding films.

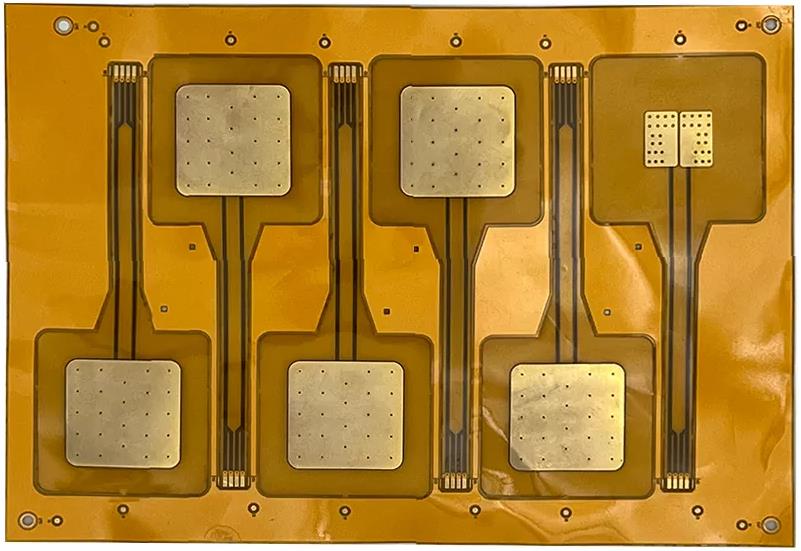

flexible FPC

Each material should be selected based on shielding performance, its impact on mechanical bending capability, and its suitability for controlled impedance design.

1. Copper layers are connected to the ground plane via stitched vias in the form of solid or cross-shaded planes. Signal layers are sandwiched between shielding layers. This shielding scheme is also used in rigid PCB designs. Solid copper layers provide a high level of shielding. Cross-shaped layers can be used if shielding is required without compromising board flexibility.

While this is a very effective shielding option, its drawbacks include a significant increase in design thickness and component cost. The additional thickness limits the design's flexibility when the flexible FPC circuit is bent into the desired shape, leading to reliability issues. Copper-shielded flexible FPC circuits are thicker than single-layer unshielded flexible FPC circuits. This type of shielding supports controlled impedance designs.

The shielding layer is connected to the ground plane via vias. The presence of vias in the flexible FPC area becomes a disadvantage. According to IPC 2223, vias are not recommended in flexible FPC sections. They act as mechanical stress concentration points while reducing flexibility.

2. Silver paste shielding is a classic choice. Compared to copper layers, silver ink offers the advantages of greater flexibility and lower cost. Although silver paste is more flexible than copper, it still requires an additional cover layer to encapsulate and protect it. This type of shielding is thinner and less expensive than copper layer shielding. A silver paste-shielded flexible FPC circuit is only 75% thicker than its unshielded variant.

The silver paste incorporates selected perforations on the main cover plate. These perforations expose the ground plane and allow for electrical interconnections. Silver paste flows into these holes, establishing a connection between the shielding layer and the ground/signal layer.

3. Specialized shielding films are the most common choice. They are suitable for dynamically bending applications and allow for the smallest possible structure. Shielding films are highly effective and used in a variety of sensitive applications.

In this structure, conductive adhesive, a metal deposition layer, and an outer insulating layer are bonded together. They are then bonded to the surface of the cover layer using heat and pressure. The grounding circuit is connected in the same way as with silver paste. Conductive adhesive can be used for bonding and electrical connection through selective orifices on the cover plate.

Shielding requirements are critical for any PCB board, and flexible FPCs are no exception. To provide functional, reliable, and cost-effective shielding, a thorough review of all electrical and mechanical design factors is necessary. If you would like us to assist in reducing EMI in your board design, please contact iPCB company.