LED technology has been developed quite mature, whether it is the raw materials or its packaging process, but some customers in the actual use of the process will still appear a lot of problems, soldering after the use of the process of dead lights, most of them appear in the soldering, such as soldering temperature, time, and in addition there is an overload of loaded use leads to insufficient heat dissipation of dead lights, transient overloading and so on.

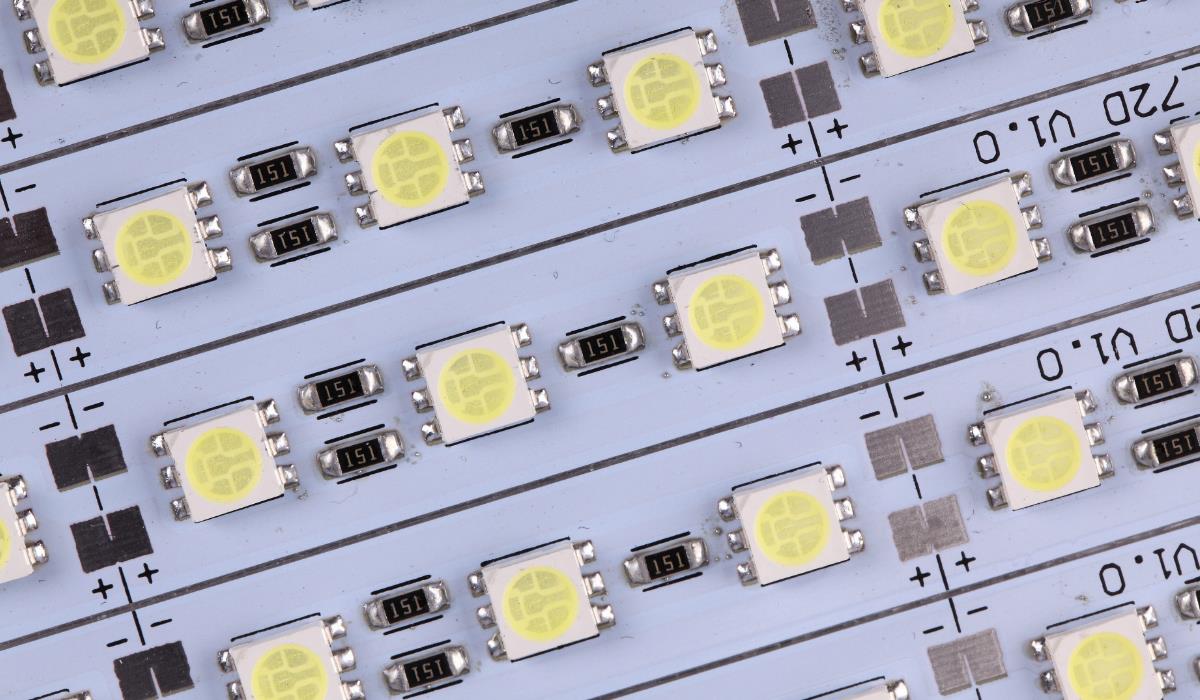

Relative to the conventional SMT SMD processing to the LED SMD is more simple,the lamp beads are more dense light board production efficiency is also very high,but in the process of LED SMD processing there are many things to note,love Pi circuit to give a brief introduction to the common LED SMD things to note.

1.LED moisture and humidity

Moisture and humidity prevention are essential production precautions in electronic processing factories,and LED SMDs are no exception. In order to avoid moisture absorption during transportation and storage, SMD LEDs are packed in moisture-proof aluminium bags.

2.LED Temperature

LED board in the production process because the PPA part of the high temperature resistance is not strong, so need to strictly control the temperature of the furnace,the temperature curve of the reflow soldering process can not exceed the maximum temperature of the board, and need to control the furnace time to avoid PCBA deformation, yellowing and other undesirable phenomena.

3.LED cleaning

SMT processing plant in the production process after the completion of most boards will have a cleaning session for the LED light board to collect can not be used indiscriminately cleaning agent,according to the actual situation of the board to choose the appropriate cleaning agent to wash the board.

When necessary to clean, the SMD LED immersed in alcohol, less than 1 minute at normal room temperature and dry naturally for 15 minutes before use. Do not use unknown chemicals to clean SMD LEDs:Unknown chemicals may damage SMD LEDs.

When using chemicals to clean the gel must be especially careful, should be some some chemical solution (such as trioxymethylene, acetone, etc.) on the surface of the LED epoxy damage and may cause discolouration, if it is necessary to clean the LED,can be used to ethanol wipe, batch, batch time at room temperature not more than 1 minute.

Ultrasonic purification will affect the LED,which is related to the output power of the ultrasonic oscillator, antiquarian ultrasonic cleaning of LEDs should be evaluated before the setting parameters to ensure that the LED will not cause damage.

4.LED Storage

After sealing the bag, the storage conditions are temperature < 40 ℃,humidity < 90% RH,the shelf life of new products is about one week.When the shelf life exceeds,need to re-bake. Non-new products are recommended to be baked before use.

Before opening the package, please check the bag for air leakage,if there is any air leakage,please re-bake before use.

After opening, please use the product under the following conditions:temperature < 30℃,humidity below 60%RH.If the product has not been used for more than 24 hours after opening,it should be baked as below before use.

Baking conditions: The product should be baked in an oven at a temperature of 70°C±5°C.The relative humidity should be ≤10% RH.Relative humidity ≤10%RH, time: 12 hours.

Take out the product from the bag and bake it again, note that the bag must be taken out and only the product is baked,and the oven door cannot be opened during the baking process.

LED

5.LED soldering

LED manual operation and soldering work

If it is SMD with side soldering bit,you can use soldering iron to solder,the soldering iron must be less than 25W,the temperature of the soldering iron must be kept below 315℃,and the soldering time can not be more than 3 seconds.The soldering iron must not touch the silicone or epoxy resin part.

If the SMD LED only has a soldering pad at the bottom,you can use a dispenser to evenly spread the tin on the corresponding soldering pads of the lamps,then use tweezers to clip the lamps one by one on the lamp bit, and then use a constant-temperature heating station to heat the soldering,the constant-temperature heating station is generally used to operate at a low temperature of 180 degrees below the operation of the more,so you need to stress the melting point of the paste when you buy the soldering paste. Or stick the lamp can be directly into the reflow soldering machine, please refer to the reflow soldering notes for specific operations!

After soldering,let it cool down until the temperature is below 40℃ before packing.

Setting the current of small power SMD LED (such as 3528 3020 3014 and 2835 small power, three chip 5050 according to the average current of the three chips), good heat dissipation under normal use of 17-20MA current, but if the use of space heat dissipation is sufficient, under the surface of the thick aluminium substrate, or the back of the board with a fan, it can be used up to 30MA, but if However, if the board has a thick aluminium substrate or a fan on the back of the board, it can be used up to 30MA, but if the board is a general glass fibre board or a flexible board, it can only be used with a current below 17MA. Medium power 2835 and 5630 5730 0.5W lamp beads can be set to 60-120MA according to the heat dissipation situation, if the heat dissipation* is sufficient,150MA.High power 5050 3535 1W lamp beads are required to use a constant current between 240-300MA,if the heat dissipation situation is sufficient, the 50501W 350MA, 3535 1/3W general purpose 600MA. If the heat dissipation is sufficient,350MA for 50501W and 600MA for 3535 1/3W general purpose. When installing a small area with many lights,the heat dissipation should be taken into consideration, and it is suitable to install a fan on the back of the board. When working at room temperature, if the temperature of the LED itself exceeds 75 degrees, it means that the overall design of the heat dissipation is seriously insufficient, we must consider improving the heat dissipation conditions or reduce the current!

Soldering iron soldering: soldering iron (maximum 30W) tip temperature does not exceed 300 degrees, soldering time does not exceed 3 seconds, soldering point should be more than 3mm away from the plastic body and recommended to be soldered under the card point.

Dip soldering: soldering temperature 260 degrees,dip soldering time not more than 3 seconds,dip soldering position at least 3mm away from the body, LED preheating temperature of 100-110 degrees, the maximum length of not more than 60 seconds.

Since the LED wafer is directly attached to the cathode support,please minimise the pressure on the LED and the thermal shock on the wafer during soldering to prevent damage to the wafer.

During and after the soldering process, do not apply any external force and vibration to the colloidal part of the LED to prevent the gold wire from breaking,in order to avoid mechanical shock or vibration after soldering the LED, measures should be taken to protect the colloid until the LED is restored to the room temperature state.

In order to avoid high temperature cutting and causing damage to the LED, please cut the legs at room temperature.

Do not solder LEDs with electricity.

6.Reflow Soldering of SMD LEDs on Tape and Reel

Please refer to the following for the temperature profile of M8 series reflow soldering:

Solder:leaded tin Solder: lead-free tin

Temperature rise slope= 4℃/s large Temperature rise slope= 4℃/s large

Pre-heating temperature= 100℃~150℃ Pre-heating temperature= 150℃~200

Preheat time= 100s large Preheat time= 100s large.

Temperature drop slope is 6℃/s large Temperature drop slope is 6℃/s large

Peak temperature= 230℃Peak temperature= 250℃Large.

Time at peak temperature ± 5°C cannot exceed 10s Time at peak temperature ± 5°C cannot exceed 10s

Temperature exceeding 183℃ must not exceed 80s. Temperature exceeding 217℃ must not exceed 80s.

7.LED static protection

The workbench in contact with LED products should be covered with protective tape and grounded reliably.

Personnel in contact with LEDs should wear good static electricity hand ring (preferably wired static electricity ring), protective gloves, conditions permit the best wear anti-static clothes, static electricity shoes and static electricity cap.

Application of the processing process in contact with the LED machinery and equipment must be reliably grounded, such as: soldering iron, cutting machine, bending machine and soldering equipment. Plasma fans can also be installed to eliminate static electricity.

In use or in the design of electronic circuits, must consider the harm of excessive current on the LED.

8.Pin Forming

LED pin shaping must be completed before welding, the corner must be away from the plastic 3mm or more to bend the bracket. The number of times the pin is folded at the same place cannot be more than 2 times, the pin is bent to 90 degrees, and then back to the original position for 1 time.

Pin moulding must be done with fixture or by professional personnel, and attention should be paid to avoid excessive first case of epoxy to cause internal gold wire breakage.

Pin shaping should ensure that the spacing between the pins is consistent with the circuit board.

When the LED in the welding process or has been welded, please do not bend the legs to avoid damage to the lamp.

9.LED Installation

Do not install LEDs with deformed pins.

When installing LEDs on the printed circuit board, the centre distance between the holes on the circuit board and the centre distance between the LED pins should be the same, if the holes have a larger distance, there will be residual stress on the pins, which may cause deformation of the resin part when soldering.

When the LED is inserted into the PCB, the holes on the PCB should match the size of the pins to avoid being too big or too small.

It is recommended to use guide bushings to locate the LEDs when installing them.

The area of each soldering pad for double pins should not be less than 4.6mm2.

Piranha: The area of each soldering pin is not less than 9.2mm2.

SMD general single crystal bracket each pin pad area of not less than 3.9 mm2.

SMD 3-in-1 bracket has a pad area of not less than 1.65mm2 per pin.

Other types of lights should be based on the actual light structure to determine the size of the pad size.

10.LED working conditions

When using LED drive current should not exceed the maximum current required by the specifications, preferably not more than 20mA, it is recommended that the drive current between 10-20 mA.

Each LED will have a different VF value,囙, in the actual circuit application, it is best to design the VF value of similar lamps connected in series on a circuit, so that the matching of different resistance value of the resistor, in order to achieve the purpose of cross-current.

The circuit must be designed to prevent over-voltage (or over-current) during switching of the LEDs, short currents or pulsed currents can damage the connection of the LEDs.

Some LEDs (blue LEDs, white LEDs, etc.) have anti-static requirements and should be installed and used with appropriate anti-static measures.

In the use of not only to consider the LED itself issued by the heat of the lamp, but also to consider the ambient temperature of the lamp's photoelectric performance. General lamps in the light, the temperature of the lamp foot should not be greater than 30 degrees. For power LEDs, the temperature at the lamp base or at the heat conductor base should not be greater than 60 degrees Celsius when the lamp is lit. If the temperature exceeds this level, consider lowering the drive current or increasing the heat dissipation area.

Be careful not to connect the LED polarity wrongly, in general, the slightly longer pin is the positive pole and the slightly shorter one is the negative pole, if the two pins are the same length, you should identify the markings carefully.

Try not to place the LED too close to the heating resistor component.

Avoid friction between LED and metal and other hard objects, and do not do sandblasting treatment to avoid replacing the optical performance.

In the process of LED chip processing there are many things to note, Audemars Piguet Circuits to give you a brief introduction to the common LED chip notes.