What is FCCL?FCCL = Flexible Copper Clad Laminate, also known as Flexible Printed Circuit Board, is a laminate formed by bonding copper foil on one or both sides of a flexible insulating material, such as polyester film or polyimide film, through a certain process, which has the advantages of being thin, lightweight and flexible. In addition to being thin, lightweight and flexible, FCCLs with polyimide films have excellent electrical and thermal properties.

The low dielectric constant (Dk) of FCCL enables fast transmission of electrical signals. Good thermal efficiency allows easy cooling of the components. Higher glass transition temperature (Tg) enables good operation at higher temperatures.

Flexible copper-clad laminates are the main material for flexible printed circuits (FPC) used in the electronics, automotive and information industries.In this field,polyimide films are mainly used as insulating base and cover films. Flexible Printed Circuits (FPC) are very suitable for three-dimensional mounting and can meet the requirements of light, thin, and short electronic devices, and are widely used in cell phones, digital cameras, laptops, and other electronic devices.FCCL is a key substrate for FPC, and the cost of FCCL accounts for 40%-50% of the cost of FPC.

Flexible Copper Clad Laminate base film and cover film need to have good flexibility, excellent insulation performance, good heat resistance, mechanical strength and other characteristics, PI film is the most preferred choice for manufacturing FCCL.

Composition of FCCL

FPC consists of a Flexible Copper Clad Laminate and a flexible insulating layer laminated with an adhesive (glue) and pressed together.It is the key substrate in the production of FPC, accounting for 40%-50% of the cost.It mainly consists of rolled copper foil, polyimide (PI) film or polyester (PET) film substrate film and adhesive, and the substrate PI film is its core raw material.

The composition of flexible laminates includes three main types of materials:

Insulating base materials: The insulating base materials for flexible laminates include polyester (PET) film, polyimide (PI) film, polyesterimide film, fluorocarbon vinyl film, imide fibre paper, and polybutylene to phthalate film. Among them, polyester film (PET film) and polyimide film (PI film) are the most widely used nowadays.

Metal conductor foil: metal conductor foil is flexible laminates with the conductor material, there are copper foil (ordinary electrolytic copper foil, high ductility electrolytic copper foil, rolling copper foil), aluminium foil and copper - beryllium alloy foil. The vast majority of copper foils are used, including electrolytic copper foil (ED) and rolled copper foil (RA).

Adhesive: Adhesive is an important part of three-layer flexible laminates, which directly affects the product performance and quality of flexible laminates. The main types of adhesives used for flexible laminates are polyester adhesives, acrylic adhesives, epoxy or modified epoxy adhesives, polyamide-imide adhesives, phenolic-butyraldehyde adhesives and so on. In the three-layer flexible laminates industry, adhesives are mainly classified into two main genres: acrylic adhesives and epoxy adhesives.

Common types of FCCL

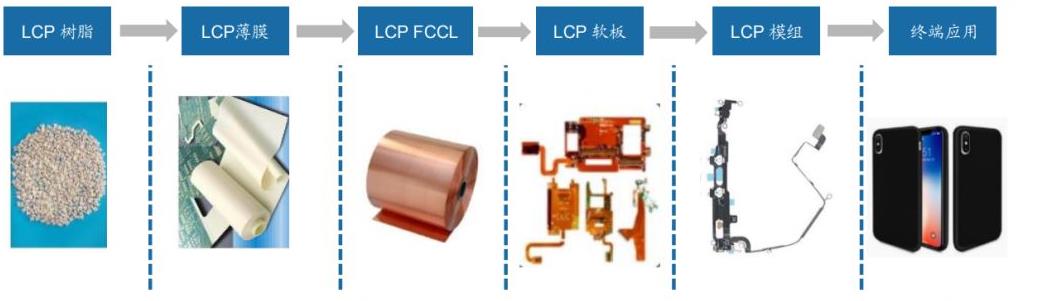

These include: PI laminating film, PET laminating film, polyester laminating film, polyamide laminating film, acrylic laminating film, acrylic laminating film, epoxy laminating film, single-side copper foil substrate, double-side copper foil substrate, electrolytic copper foil substrate, calendered copper foil substrate, liquid crystal polymer (LCP) film,PI film substrate, PET film substrate, PVC film substrate, PEN film substrate, polyamide copper foil substrate, polyester copper foil substrate, PVC copper foil substrate, PTFE copper foil substrate, non-adhesive copper foil substrate, double-sided copper foil non-adhesive substrate, single-sided copper foil non-adhesive substrate, acrylic adhesive sheet, acrylic adhesive sheet, epoxy resin adhesive sheet.

Common thickness of laminating film: 25 μm, 30 μm, 35 μm, 36 μm, 38 μm, 40 μm, 42 μm, 50 μm, 60 μm, 75 μm, 80 μm, 100 μm, 115 μm, 120 μm, 125 μm, 160 μm, 320 μm.

Common widths of laminating film: 120 mm, 130 mm, 150 mm, 250 mm, 260 mm, 270 mm, 280 mm, 300 mm, 304 mm, 305 mm, 310 mm, 330 mm, 450 mm, 500 mm, 510 mm, 550 mm, 600 mm, 610 mm, 630 mm, 750 mm, 800 mm, 810 mm, 1220 mm, 1300 mm.

Common lengths of laminating film: 250mm, 300mm, 305mm, 420mm, 450mm, 500mm, 600mm, 610mm, 630mm, 750mm, 800mm, 810mm, 1220mm, 1300mm, 25M, 27.4M, 50M, 100M, 600M, 1000M.

FCCL Copper Clad Base Material Common Thicknesses

The main suppliers of FCCL copper foil substrate are: Nippon Steel, Nippon Mektron, Arisawa, Toray, Mitsui Chemical, Nitto Denko, 3M, DuPont Taijou, Taihong, Jangjie Si, Rusheng, Sunny, and so on.

Features

In addition to the advantages of thinness, lightness, and flexibility, FCCL with polyimide film has excellent electrical, thermal, and heat resistance properties. Its low dielectric constant (Dk) enables fast transmission of electrical signals. Good thermal efficiency allows for easy cooling of the components. The higher glass transition temperature (Tg) allows the components to operate well at higher temperatures. Since most of FCCL products are supplied in continuous roll form, the use of FCCL in the production of circuit boards facilitates the automated continuous production of FPCs and the continuous surface mounting of components on FPCs.

Application

FCCL is widely used in aviation aerospace equipment, navigation equipment, aircraft instrumentation, military guidance systems and mobile phones, digital cameras, digital camcorders, car satellite orientation devices, LCD TVs, notebook computers and other electronic products.

Due to the rapid development of PCB and electronic technology, the output of FCCL has been growing steadily and the production scale has been expanding, especially the high performance flexible laminates with polyimide film as the substrate, whose demand and growth trend are more prominent.