Flex PCB Assembly refers to the complete assembly process of component mounting, soldering, inspection, and testing on flexible printed circuit boards, also known as flexible circuit board assembly or FPC assembly.

Compared to traditional rigid PCB assembly, the main advantages of flexible PCBA (Flex PCB Assembly) are extreme thinness and lightness, high flexibility, space saving, and higher integration (can replace multiple boards + connectors), enabling three-dimensional wiring, improving signal integrity, and adapting to harsh environments. Although the manufacturing and design complexity and cost are relatively higher, it is suitable for wearable devices, medical devices, aerospace, and other fields.

Advantages of Flexible PCBA

Enhanced Signal Integrity

FPC is made with carefully selected materials, significantly reducing signal attenuation and contributing to excellent performance in ultra-high-speed signal transmission.

Provides excellent impedance control

FPC conductors and shielding are manufactured with high-precision tolerances to ensure consistent impedance and prevent signal attenuation, data loss, and electromagnetic interference in high-performance devices.

Can be used at extreme temperatures

FPC uses materials with highly matched coefficients of thermal expansion, improving reliability in high temperatures, low temperatures, and environments with drastic temperature fluctuations. This minimizes the impact of thermal stress caused by temperature cycling, effectively preventing problems such as FPC cracking and warping.

Simplified thermal management

The advanced materials and thin structure design of FPC reduce the need for double-sided heat dissipation, helping to dissipate heat quickly and effectively preventing heat accumulation.

Reduced space requirements

FPC adopts a three-dimensional design, easily adapting to the confined spaces of various small devices through folding or wrap-around packaging.

Minimizes weight

Compared to traditional circuit boards, FPC is significantly thinner and lighter, reducing the weight of small devices.

Typical Process Flow of Flex PCB Assembly

The process flow of Flex PCB Assembly covers the entire process from bare board to final electronic product assembly. The main steps are as follows:

1. Incoming Material Inspection (IQC)

Appearance, dimensions, and basic electrical inspections are performed on FPC boards and components to ensure they meet assembly requirements.

2. Fixture and Carrier Board Design

Due to the inherent softness of flexible PCBs, they cannot be processed through reflow soldering and assembly directly like rigid PCBs. Custom fixtures or carrier boards are usually required to ensure flatness.

3. Solder Paste Printing

Solder paste is applied to the PCB pads through screen printing. Solder paste is a mixture of solder and flux, used to connect component leads and PCB pads.

4. Pick and Place:

Components such as chips, resistors, capacitors, and ICs are placed onto the FPC using a pick-and-place machine.

Reflow Soldering:

The FPC PCB with components attached is passed through a reflow soldering oven. The temperature profile needs to be strictly controlled to prevent FPC deformation or material aging.

5. Inspection and Testing

This includes AOI, X-ray, and functional testing to ensure reliable soldering and electrical performance.

Technical Challenges of Flex PCB Assembly

Finer Traces and Pads: FPCs are often used in high-density designs, requiring higher precision in stencil openings, solder paste types, and placement accuracy.

Different Physical Properties: Compared to traditional rigid PCBs, FPC materials are soft and easily deformed, making positioning and fixing difficult.

Different Thermal Expansion Coefficients: The thermal expansion coefficients of FPCs, components, and rigid boards differ significantly, easily generating stress during reflow soldering.

Easy to Damage with Improper Handling: Improper handling by assembly personnel can easily damage flexible circuit boards. Soldering and rework require trained personnel.

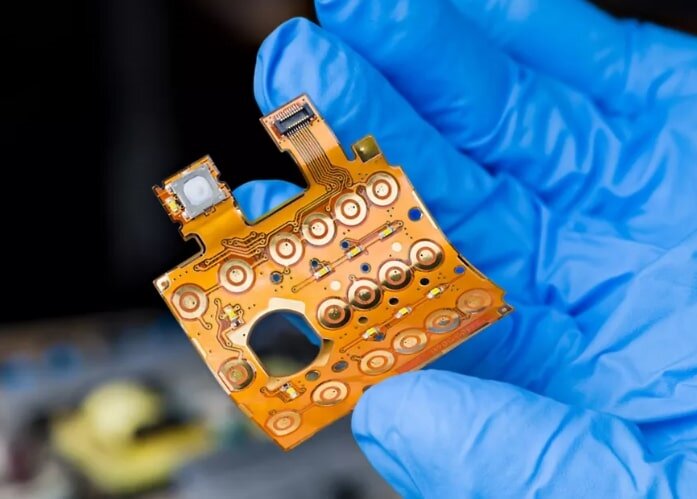

flex pcb assembly

Suggestions for Choosing a Flex PCB Assembly Supplier

When choosing a flex PCB assembly supplier, it is recommended to focus on the following points:

Whether they have one-stop service capabilities for FPC manufacturing + PCBA assembly

Whether they have inspection equipment such as AOI and X-ray to effectively control welding quality

Whether they have successful cases and mass production experience in relevant application fields

Whether they can provide engineering support and DFM suggestions to help reduce risks at the design stage

These factors will directly affect the product yield, reliability, and delivery time. iPCB company possesses mature manufacturing and assembly experience in the field of flexible PCB assembly, providing one-stop services from flexible PCB manufacturing and component placement to testing and inspection. Through a comprehensive quality control system, we assist customers in achieving stable and efficient product delivery.

Flex PCB assembly, as a core link in flexible electronics manufacturing, is constantly evolving with the development of electronic products. It not only tests manufacturing capabilities but also engineering experience and quality management levels. Through reasonable material selection, process control, and quality inspection, flex PCB assembly can achieve lighter, thinner, and more flexible product designs while ensuring high reliability.