Flex PCB uses flexible substrates made of printed circuit boards with graphics, composed of an insulating substrate and conductive layer, insulating substrate and conductive layer can be between the binder. Flex PCB can not be applied to too high on-state current or voltage, so the application of high-power electronic circuits can hardly be seen in the design of the flexible board, but rather in the small-current, low-power consumer electronics, flexible boards After the 1990s, the application of Flex PCB gradually expand the field of cell phones, PDAs, laptops, digital cameras, digital video cameras, satellite positioning devices, flat panel displays, IC packaging, automotive electronics and other products, the reason is that the transformation of consumer electronics products to portable, small and thin and light use of demand.

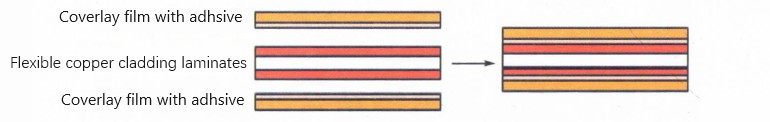

Flex PCB laminates are made by coverlay flex pcb of copper foil on one or both sides of a flexible dielectric insulating film, and flexible copper laminates are the basic processing substrate for flexible printed circuit boards. The basic structure of Flex copper laminates substrate includes insulating base film material, adhesive, and copper foil. Commonly used insulating base film materials are polyimide, polyester, and polyfluoro types, of which polyimide and polyester film are currently the main production of flexible printed circuit boards.

Polycoolimide (polyimide, Pl) is a class of polymers containing an imide ring on the main chain, which includes the most important polymer phthalimide structure. Polyester (polyethylene terephthalate, PET) belongs to the polymer compounds, is by terephthalic acid (PTA) and ethylene, glycol (EG) through the polycondensation to produce polyethylene terephthalate, some of them - PET and then through the underwater cut grain and ultimately generated. Polytetrafluoroethylene (polytetrafluoroethylene, PTFE) is a synthetic polymer material that uses gas to replace all hydrogen atoms in polyethylene. This material is resistant to acids, alkalis, and various organic solvents, and is virtually insoluble in all solvents. In addition, PTFE is resistant to high temperatures and it has an extremely low coefficient of friction.PTFE film materials are used only for high-frequency products that require a low dielectric constant.

The adhesive binds the copper foil to the substrate film. The overlay is an insulating protective layer that covers the surface of the flexible printed circuit board. It protects the surface conductors and increases the substrate's strength. The cover layer is usually an insulating film of the same material as the substrate, such as PET or PI film coated with an adhesive.

The covering layer is the biggest difference between flexible boards and rigid boards, its role beyond the rigid board solder resist film, which not only plays a role in solder resist, but also makes flexible circuits are not subject to dust, moisture, and chemical erosion and reduces the impact of stress in the process of bending, it is required to withstand long-term flexure. The cover layer is covered in the etching of the circuit above, which requires it to have a good shape to meet the requirements of bubble-free lamination. Covering layer material selection and the same material as the substrate, in the flexible media film coated with a layer of adhesive film on one side, and then in the adhesive film covered with a layer of protective film that can be removed.

The layer of protective film can be removed, this layer of protective film is usually only in the cover layer, and the etched circuit is aligned to tear off, which is a complex production process. Covering layer materials can be divided into dry film type and ink type according to their form, according to whether they are light-sensitive, and are divided into non-photosensitive covering layer and light-sensitive covering layer.

(1) Polyimide has excellent heat dissipation properties and can withstand the thermal shock of high-temperature processing of lead-free soldering;

(2) For smaller devices that require more emphasis on signal integrity, most device manufacturers tend to use flex circuits;

(3) Polyimide has a high glass transfer temperature and high melting point characteristics, generally to be processed at 350 ℃ or more;

(4) in organic solvency, polyimide is not soluble in general organic solvents.

The shrinkage of the flex pcb material is mainly related to the base material PI and glue, that is, the imidization of PI has a great relationship, the higher the degree of imidization, the stronger the controllability of shrinkage.

Production process

Opening - Etching - Surface treatment - Stripping - Dry-film application - Antioxidant treatment - Exposure and development - Finished products