Flexible PCB, often referred to as a flexible board, is a printed circuit board made from flexible insulating materials such as PI or PET as the substrate. The biggest difference between it and traditional rigid PCB lies in its excellent flexibility, which allows it to bend, roll, and fold freely. It can be placed according to the requirements of spatial layout, and move and expand freely in three-dimensional space, thus achieving the integration of component assembly and wire connection.

Types of flexible PCBs

1. Single-sided flexible PCB: It has the simplest structure, consisting of only one layer of copper foil, and is primarily used for simple signal transmission and connection scenarios. It can be found in small electronic devices that do not require high circuit complexity.

2. Double-sided flexible PCB: It features a conductive copper layer on each side of a dielectric material, with polyimide (PI) serving as the medium in between. Compared to single-sided flexible PCBs, it enhances circuit density and meets the requirements of products that demand a certain level of circuit integration.

3. Multi-layer flexible PCB: It is suitable for high-density integrated circuits, and is commonly used in the motherboards of foldable screen phones. It is formed by separating and encapsulating multiple copper layers with dielectric layers, enabling extremely complex circuit layouts within a limited space, and effectively driving the development of electronic products towards high performance and miniaturization.

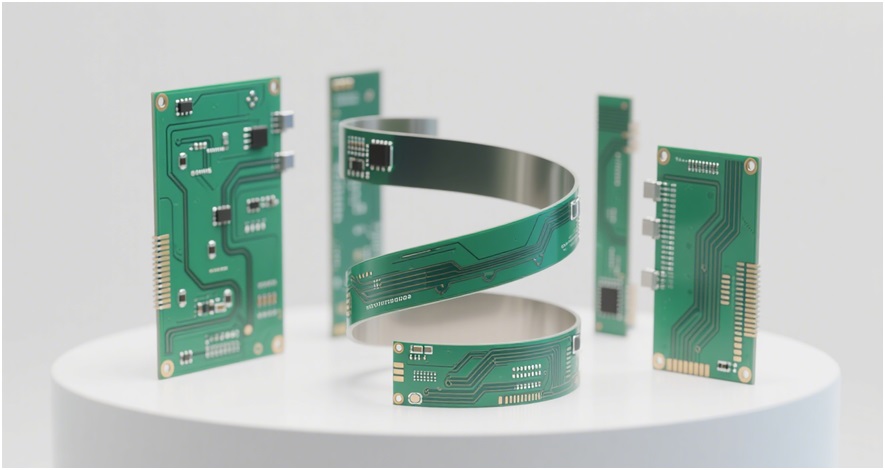

4. Rigid-flex PCB: This type of PCB cleverly combines the advantages of rigid PCBs and flexible PCBs. It uses rigid PCBs in key areas that require rigid support, while using flexible PCBs in places where flexibility is needed. This type of PCB can provide stable rigid support in critical areas while maintaining overall flexibility, and is widelyused in precision instruments, aerospace equipment, and other applications.

Figure 1: Rigid-flex PCB

Key materials for flexible PCBs:

1.Substrate: Commonly used substrates include polyimide (PI) and polyethylene terephthalate (PET). Among them, PI stands out as the preferred material for high-end flexible PCBs due to its excellent heat resistance, chemical resistance, and mechanical strength. In harsh environments such as high temperature and high humidity, flexible PCBs made of PI substrate can still operate stably.

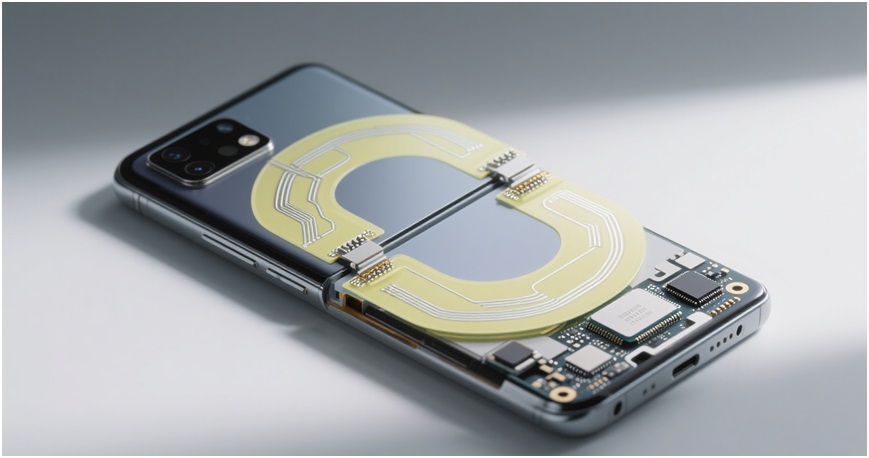

Figure 2: PI and PET flexible PCB

2. Copper foil: It is mostly made of rolled and annealed copper (ROL), which has good ductility and can withstand multiple bending, ensuring that the conductivity of the circuit remains unaffected during repeated bending of flexible PCBs.

3. Adhesive: Used for interlayer bonding, common adhesives include epoxy resin and acrylic resin. In recent years, adhesiveless structures have gradually gained popularity in order to reduce thickness and enhance heat resistance.

4. Cover film: Its primary function is to protect the circuit and provide insulation, typically consisting of a PI film with an adhesive layer. It effectively prevents the circuit from being corroded by the external environment, thereby extending the lifespan of the flexible PCB.

Manufacturing challenges of flexible PCBs

The manufacturing process of flexible PCBs is complex and requires extremely high precision

1. High difficulty in precision processing: Flexible PCBs are typically thin, ranging from 0.05mm to 0.2mm in thickness, making them highly susceptible to deformation during processing, which significantly impacts the accuracy of processes such as laser drilling, exposure, and etching. To address this issue, special flexible fixtures or vacuum adsorption platforms are often required during manufacturing to ensure precise alignment during processing.

2. Limited improvement in line density: With the rapid development of high-end applications such as 5G communication and high-definition displays, the requirements for line width/line spacing (L/S) of flexible PCBs have become increasingly stringent, currently reaching the 30μm level. However, due to the characteristics of flexible materials, the difficulty of processing ultra-fine lines is much higher than that of rigid PCBs. It requires not only higher precision exposure and etching processes, but also strict control over the adhesion of copper foil to prevent peeling or fracture.

3. Rigorous reliability testing requirements: In practical applications, flexible PCBs often need to withstand multiple bending cycles. Therefore, they must undergo rigorous dynamic bending tests to simulate the bending conditions they encounter in real-world use. Additionally, high-temperature and high-humidity aging tests (such as those conducted in an 85°C/85% RH environment) are also necessary to ensure their reliability in harsh environments. Furthermore, in special fields such as wearable devices or medical electronics, they must also meet biocompatibility standards, which undoubtedly further increases the manufacturing difficulty.

Application scenarios of flexible PCBs

1. Consumer Electronics field

Foldable screen phones: Flexible PCBs play a pivotal role in foldable screen phones. They are responsible for connecting components such as the mainboard, screen, and hinge, ensuring that the circuit functions properly and signal transmission is stable during the folding and unfolding process of the phone. For instance, Samsung's Galaxy Fold series of foldable screen phones extensively utilizes advanced flexible PCB technology, achieving flexible folding of the screen and efficient connection of complex circuits.

Figure 3: Flexible PCB folding phone application

Wearable devices:

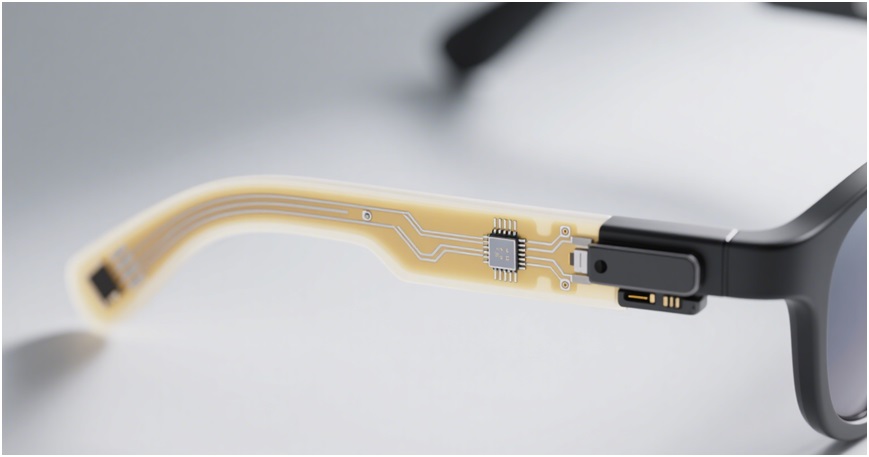

In wearable devices such as smartwatches, smart bracelets, and smart glasses, flexible PCBs greatly enhance wearing comfort due to their ultra-thin and bendable characteristics. They can tightly connect tiny chips, sensors, and other components, achieving miniaturization and multifunctionality within a limited space. For example, Apple's Apple Watch cleverly connects various sensors, processors, and other components through flexible PCBs, not only making the device appear thinner and lighter but also improving overall performance.

Figure 4: Flexible PCB smart glasses application

2. Automotive electronics field

Battery management system: In new energy vehicles, flexible PCBs are widely used in the battery management system. They can adapt to the complex spatial structure inside the vehicle's battery pack, enabling precise monitoring and control of battery cells, and ensuring the safe and stable operation of the battery.

Autonomous driving sensors: With the rapid development of autonomous driving technology, the requirements for sensor accuracy and reliability are becoming increasingly stringent. Flexible PCBs can tightly connect multiple sensors together and adapt to the vibrational environment during vehicle operation, ensuring stable transmission of sensor signals. For example, Tesla's autonomous driving sensor system utilizes flexible PCBs to achieve efficient connection and layout of sensors.

In-vehicle entertainment system: In the in-vehicle entertainment system, flexible PCBs enable flexible connections between displays, audio systems, and other devices, meeting the diverse spatial layout requirements inside the car and providing a better entertainment experience for drivers and passengers.

3. Medical equipment field

o Cardiac pacemaker: Due to its biocompatibility and flexibility, flexible PCBis an ideal choice for implantable medical devices such as cardiac pacemakers. It can integrate complex circuits within a small space, ensuring long-term stable operation of the device and providing reliable protection for patients' lives and health.

Flexible sensors: In the field of medical monitoring, flexible sensors can be used to monitor various physiological parameters of the human body. Flexible PCBs can tightly connect sensors with signal processing circuits and conform to human skin, enabling precise acquisition and transmission of physiological signals. For example, some wearable medical monitoring devices, by connecting flexible sensors through flexible PCBs, can monitor heart rate, blood pressure, body temperature, and other parameters of the human body in real time.

Figure 5: Flexible PCB monitors human physiological parameters

The cost of flexible PCBs varies depending on the number of layers and substrate materials. In practical applications, it is necessary to choose single-sided, double-sided, or multi-layer flexible boards according to specific needs. iPCB is a rigid-flex PCB supplier that offers the cheapest prices for flex and screen-printed circuit boards. iPCB quickly responds to requests for flex PCBs quotations and provides one-stop services for rigid-flex PCB assembly. Our goal is to manufacture the best rigid-flex PCB prototypes.