FPC is a flexible circuit board with high wiring density, light weight, and thin thickness. It has both high reliability and excellent bendability, FPC has been increasingly used in our daily life, but FPC flexible board production process do you know?

Single-sided FPC process

Material opening → drilling → paste dry film → alignment → exposure → developing → etching → stripping → surface treatment → paste cover film → pressing → curing → surface treatment → immersion nickel gold → printing characters → cutting → electrical testing → punching → final inspection → packaging → shipment.

Double-sided FPC Process

Material opening → drilling → PTH → plating → pre-treatment → dry film → alignment → exposure → development → graphic plating → stripping → pre-treatment → dry film → alignment exposure → development → etching → stripping → surface treatment → overlay film → pressing → curing → immersion in nickel-gold → printing characters → shearing → testing → rinsing → final inspection → packaging → shipment.

The production process of FPC flexible board can also be downloaded:![]() FPC Soft Board Production Process Description.ppt

FPC Soft Board Production Process Description.ppt

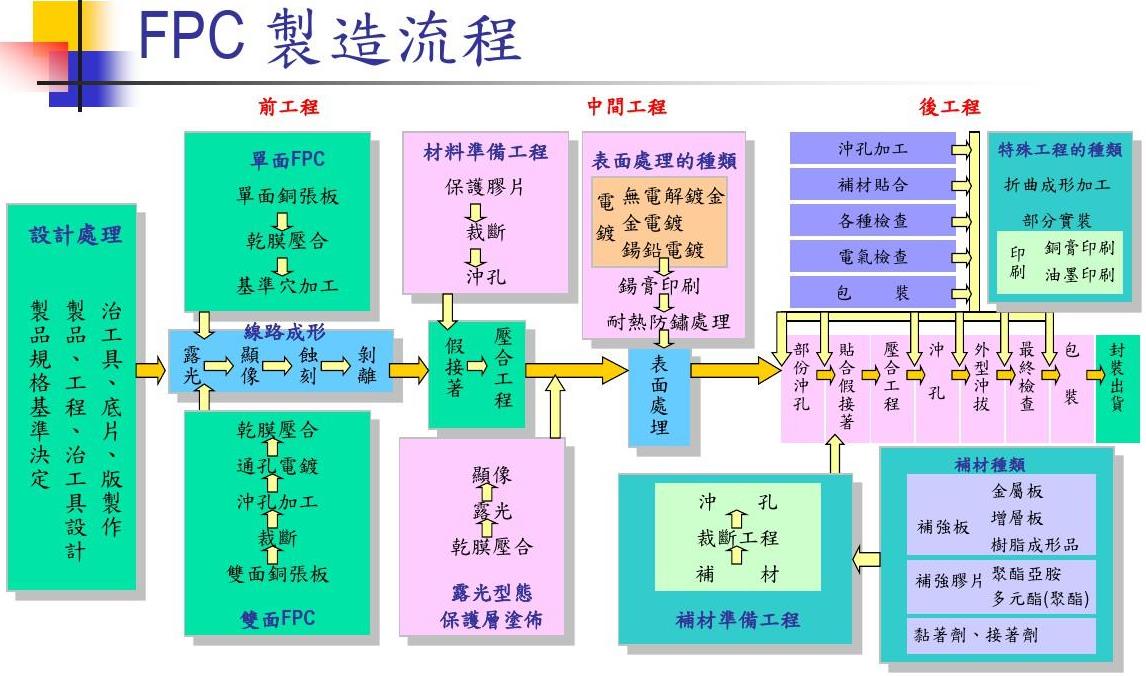

Production process of FPC flexible boards

Part of the FPC production process

1.FPC Flexible board open material

Except for some materials, the materials used for FPC flexible board are basically in roll form. Since not all processes must be processed with tape and reel technology, some processes must be cut into pieces to be processed, such as the drilling of metallised holes in double-sided FPC flexible boards, which can only be drilled in the form of pieces at present, so the first process of double-sided FPC flexible boards is to open the material. Flexible copper-clad laminates have a very poor ability to withstand external forces and are easily injured. If it is damaged during unrolling, it will have a serious impact on the pass rate of the subsequent processes. Therefore, even if it seems to be a very simple opening, it is necessary to pay enough attention to ensure the quality of the material. For small quantities, hand shears or roller cutters can be used. For large quantities, automatic shears can be used. Whether it is single-sided, double-sided copper foil laminate or cover film, the accuracy of the opening dimensions can reach ±0.33. The reliability of the opening is high, the opened material is automatically stacked neatly, and there is no need for personnel to collect the material at the exit. The damage to the material can be controlled to a minimum, and the material is almost free of wrinkles and scratches by using the change in the size of the feeding roller. Moreover, the latest device can also be etched on the tape process after the FPC flexible board for automatic cutting, the use of optical sensors can be detected to locate the corrosion pattern, for automatic opening and positioning, opening accuracy of 0.3mm, but can not be used to open the border as a positioning of the subsequent processes.

2.FPC drilling through-hole

FPC flexible board through-hole and rigid FPC can also use CNC drilling, but is not suitable for tape and reel double-sided metallised hole circuit hole processing. With the high density of the circuit pattern and the small aperture of the metallised holes, coupled with the boundaries of the aperture diameter of the CNC drilling, many new drilling techniques have now been put into practical use. These new drilling techniques include plasma etching, laser drilling, punching of small apertures, chemical etching, etc. These drilling techniques are easier than CNC drilling to meet the hole formation requirements of tape and reel technology.

3.CNC drilling

Most of the holes in double-sided FPC flexible boards are still drilled with CNC drilling machines, which are basically the same as those used for rigid FPCs, but the drilling conditions are different. Since the FPC flexible board is very thin, it can be drilled by overlapping several pieces, and if the drilling conditions are good, it can be drilled by overlapping 10 to 15 pieces together. The pads and covers can be made of paper-based phenolic laminates or glass-fibre cloth epoxy laminates, and aluminium plates 0.2 to 0.4 mm thick can also be used. Drill bits for FPC flexible boards are available in the market. Drill bits for rigid FPC drilling and milling cutters for profile milling can also be used for FPC flexible boards.

The processing conditions for drilling holes, milling the cover film and reinforcing the shape of the board are basically the same, but since the adhesive used for FPC flexible board material is soft, it is very easy to adhere to the drill bit, so it is necessary to check the status of the drill bit frequently and increase the rotational speed of the drill bit appropriately. Drilling holes for multi-layer FPC flexible boards or multi-layer rigid-flexible FPCs requires special care.

4.FPC Punching

Punching small apertures is not a new technology, but has been used for mass production. Since the tape reeling process is a continuous production, there are many examples of using punching to process the through holes of the tape. However, the batch punching technology is limited to punching holes with a diameter of 0.6 to 0.8mm, which has a long processing cycle and requires manual operation compared to CNC drilling. Since the initial process size is very large, the punching moulds have to be large accordingly, and the moulds are thus very expensive. Although the mass production is beneficial to cost reduction, there is a big depreciation burden on the equipments, and the small batch production and flexibility can not compete with CNC drilling, so it has not been popularised so far. Therefore, it has not been popularised so far.

However, in recent years, punching technology has made great progress in both mould precision and CNC drilling, and the practical application of punching on FPC flexible boards has become very feasible. The latest tooling technology can produce holes with a diameter of 75um for punching adhesive-free copper-clad laminates with a substrate thickness of 25um, with high punching reliability, and even holes with a diameter of 50um can be punched if the punching conditions are suitable. Punching devices are also digitally controlled and moulds can be miniaturised, so they can be well used for punching holes in FPC flexible boards, whereas digitally controlled drilling and punching cannot be used for blind hole processing.

5.FPC laser drilling

Laser can be used to drill the smallest through holes. The laser drilling machines used to drill through holes in FPC flexible boards include excited excimer laser drills, impact carbon dioxide laser drills, YAG (perylene aluminium garnet) laser drills, and argon laser drills.

Impact carbon dioxide laser drilling machine is only able to drill holes in the insulating layer of the substrate, while YAG laser drilling machine can drill holes in the insulating layer of the substrate and copper foil, and the speed of drilling the insulating layer is significantly faster than that of drilling the copper foil, and it is not possible to use the same type of laser drilling machine to carry out all the drilling processes with high productivity. Generally, the copper foil is first etched to form the hole pattern, and then the insulating layer is removed to form the through-hole, so that the laser can drill holes with extremely small diameters. This allows the laser to drill holes of extremely small diameters. However, the accuracy of the position of the upper and lower holes may limit the diameter of the holes. In the case of drilling blind holes, as long as the copper foil is etched off on one side, there is no problem with the accuracy of the upper and lower positions. This process is similar to plasma etching and chemical etching described below.

At present, the holes produced by stimulated excimer laser (SEL) are the smallest ones. Stimulated excimer laser is an ultraviolet ray that directly destroys the structure of the resin in the base layer, causing the resin molecules to disintegrate and generating very little heat, so that the heat damage around the holes can be limited to a minimum, and the walls of the holes are smooth and vertical. If the laser beam can be further reduced, it is possible to process holes with a diameter of 10 to 20 um. Of course, the larger the aperture to thickness ratio, the more difficult it is to perform wet copper plating. The problem of drilling holes by excited excimer laser technology is that the decomposition of polymers produces carbon black attached to the hole wall, so it is necessary to remove the carbon black by some means of cleaning the surface before plating. However, when laser drilling blind holes, there is also a problem with the uniformity of the laser, which can cause a bamboo-like residue.

The biggest difficulty of excited excimer laser is that the drilling speed is slow and the processing cost is too high. Therefore, it is only used for high-precision and high-reliability micro-hole processing.

Impact carbon dioxide laser generally uses carbon dioxide gas as the laser source and radiates infrared rays. Unlike excited excimer laser which burns and decomposes resin molecules due to thermal effect, it is thermally decomposed and the shape of the processed holes is much poorer than that of excited excimer laser, and the diameter of the processed holes is basically 70 to 100 um. However, the processing speed is obviously much faster than that of excited excimer laser, and the drilling cost is much lower. The cost of drilling is also much lower. Even so, it is still much more expensive than the plasma etching and chemical etching methods described below, especially when the number of holes in the tissue area is large.

One thing to note about impact CO2 lasers is that when processing blind holes, the laser can only be emitted to the surface of the copper foil, and there is no need to remove any organic matter from the surface. In order to stabilise the cleaning of the copper surface, chemical or plasma etching should be used as a post-processing method. From the technical possibility to consider, laser drilling process used in the tape process basically has no difficulty, but considering the balance of the process and the proportion of investment in equipment, it does not have an advantage, but the tape chip automated bonding process (TAB, Tape Automated Bonding) width is narrow, the use of the tape process can improve the drilling speed, in this regard there have been practical examples. There are already practical examples of this.

6.Hole metalisation

The hole metallisation of FPC flexible board is basically the same as the hole metal process of rigid FPC.

In recent years, instead of chemical plating, the formation of carbon conductive layer technology used to form a direct plating process. This technology has been introduced to the hole metallisation of FPC flexible boards.

FPC flexible board because of its soft, need to have a special fixed fixture, fixture not only the FPC flexible board fixed, but also in the plating solution must be stable, otherwise the thickness of the copper plating is not uniform, which is also in the etching process caused by broken lines and bridging the important reasons. To obtain a uniform copper layer, the FPC board must be taut in the fixture, and efforts must be made on the position and shape of the electrodes.

Hole metallisation outsourcing processing, to avoid as far as possible outsourcing to factories without experience in FPC soft board poration, if there is no FPC soft board dedicated plating line, the quality of poration can not be guaranteed.

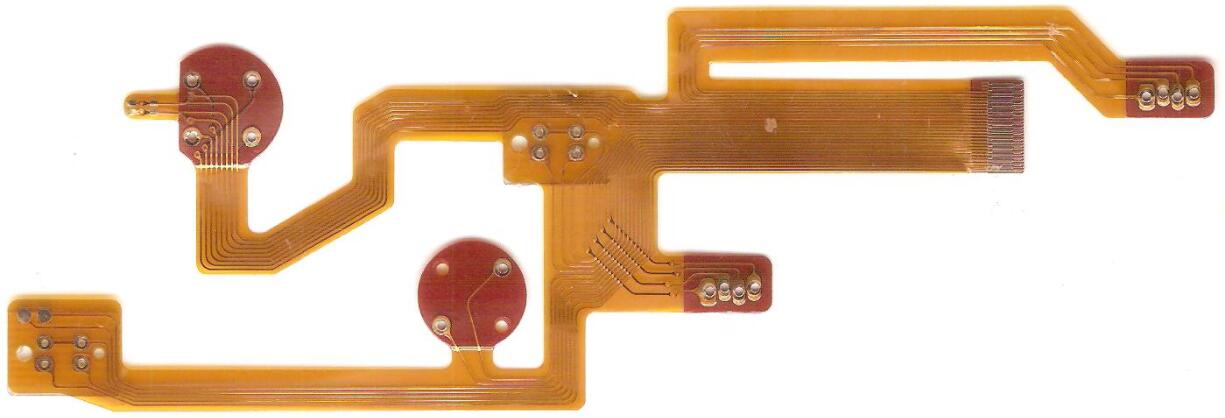

FPC Flexible Board

7.Cleaning of copper foil surface

In order to improve the adhesion of the anti-corrosion mask, the surface of the copper foil should be cleaned before coating the anti-corrosion mask, even this simple process needs special attention for FPC flexible board.

Generally, there are two cleaning processes: chemical cleaning and mechanical grinding. For the production of precision graphics, most of the cases combine the two cleaning processes for surface treatment. Mechanical grinding is done by brushing. Brush material that is too hard will damage the copper foil, while one that is too soft will not grind sufficiently. Nylon brushes are generally used, and the length and hardness of the brushes must be carefully studied. Use two polishing rolls, placed on top of the conveyor belt, rotating in the opposite direction to that of the belt, but if the pressure of the polishing rolls is too high, the substrate will be stretched by a great tension, which is one of the important reasons for the dimensional changes.

If the surface treatment of copper foil is not clean, then the adhesion with the anti-etching mask is poor, which will reduce the pass rate of the etching process. Recently, the surface cleaning process can be omitted in the case of single-sided circuits due to the improvement in the quality of copper-clad boards. However, surface cleaning is essential for precision patterns of 100 μm or less.

Anti-corrosive coating - Double-sided FPC process technology: The coating method of anti-corrosive agent is divided into the following three methods according to the precision of the circuit pattern and the production volume: silk screen leakage printing method, dry film/photographic method, and liquid anti-corrosive agent photographic method.

Anti-corrosive inks are printed directly onto the surface of the copper foil by the silk screen printing method, which is the most commonly used technique and is suitable for mass production at low cost. The precision of the formed line pattern can reach line width/spacing of 0.2~0.3 mm, but it is not suitable for more precise patterns. With microfabrication this method is gradually becoming unsuitable. Compared with the dry film method described below, it requires operators with a certain level of skill, who must be trained for many years, which is an unfavourable factor.

The dry film method is capable of producing line width patterns of 70 to 80 μm as long as the equipment and conditions are in place. Nowadays, most of the precision patterns below 0.3mm can be formed by the dry film method to form anti-corrosive line patterns. The thickness of the dry film is 15 to 25 μm, and conditions permit the production of 30 to 40 μm line width patterns at batch level.

When selecting a dry film, it is necessary to determine it based on the compatibility with the copper foil sheet and the process, and through testing. Even if the experimental level is good, it does not necessarily have a high pass rate when used in mass production. FPC flexible board is thin and easy to bend, if you choose a harder dry film is more brittle and poor mobility, so there will be cracks or peeling and thus reduce the pass rate of etching.

Dry film comes in rolls, which makes the production equipment and work easier. The dry film consists of a three-layer structure of a thin polyester protective film, a photoresist film and a thicker polyester release film. Before lamination, the release film (also known as diaphragm) should be peeled off first, and then heat rollers will be pressed on the surface of the copper foil, and then torn off the top protective film (also known as the carrier film or cover film) before development. Generally, there are orientation holes on both sides of the FPC flexible board, and the dry film can be a little bit narrower than the flexible copper foil board to be laminating. The automatic laminating device for FPC is not suitable for laminating FPC flexible boards, and some design changes must be made. Since dry film lamination has a high line speed compared to other processes, many PCB factories do not use automated lamination, but use manual lamination.

After the dry film is applied, it should be left for 15 to 20 minutes before exposure in order to make it stable.

If the line width is below 30 μm, the pass rate will be significantly reduced if the pattern is formed by dry film. Liquid photoresist is used instead of dry film for mass production. The thickness of the coating varies depending on the coating conditions. If a liquid photoresist with a thickness of 5 to 15 μm is coated on a 5 μm thick copper foil, the laboratory standard is able to etch a line width of 10 μm or less.

Liquid photoresist, after coating, must be dried and baked. Since this heat treatment will have a great impact on the performance of the anticorrosion film, the drying conditions must be strictly controlled.

Above is the introduction of FPC flexible board process shared by iPCB, for more information, welcome to exchange.