Many flexible pcb applications require designs to be exposed to temperatures well above standard room temperature, or to operate continuously at elevated temperatures. These requirements exceed those of FPC or FPC connector assemblies.

Flexible pcb materials are rated to withstand RoHS reflow temperature profiles. These FPCs range from short-term high temperature exposure, such as autoclaving for medical devices, to designs that operate continuously at extreme temperatures, such as downhole drilling electronics, and applications that can see temperatures above 200°C for extended periods of time.

Reflow Temperature Profile

To meet these requirements, FPC board manufacturers offer a variety of flexible FPC materials with varying maximum operating temperature capabilities. The end result is a reliable flexible FPC design.

Flexible FPC Materials and Constructions

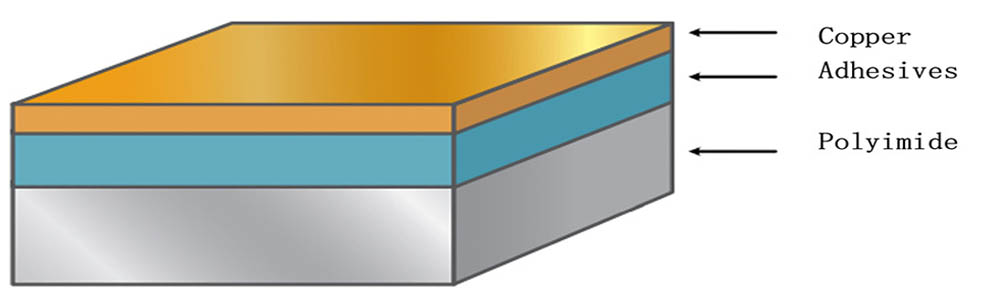

The Flex Core of the flexible pcb substrate has two different constructions. They differ in how the circuit copper foil layer is attached to the central polyimide core. The original flexible core material uses a layer of adhesives to bond the copper to the polyimide core. The latter material type calenders copper or electrolytic copper directly on the polyimide, eliminating all adhesive layers. This type of flexible core is called a "non-adhesive flexible core." Once the temperature requirement is above the general requirement of 85°C, standard practice is to use an adhesive-free flexible core.

Flexible Circuit Board FPC Construction

Coverlays consist of an outer polyimide layer and a layer of flexible adhesive. They are laminated onto the circuit surface under heat and pressure, and the adhesive is used to connect the coverlay and the encapsulated circuit. There are three different types of adhesives to choose from, all of which have different temperature rates.

Reinforcements are available in polyimide, FR4, stainless steel, and aluminum. The same adhesive as the coverlays or in some cases adhesive is used to connect the reinforcements. The only temperature-related considerations are whether FR4 is used, and the type of adhesive used for the connection.

Adhesives are available from multiple suppliers and have a wide range of materials. 3M and TESA are the most commonly used material brands. The selected adhesive needs to be reviewed for performance to ensure that it meets the temperature and adhesion requirements of the design specification.

Flexible FPC circuit boards can use additional copper layers, specialized shielding films, or use a layer of silver paste for EMI shielding of flexible FPCs. The use of silver paste has decreased significantly over the past 10 years and is no longer generally recommended.

Flexible circuit board FPC is composed of 3 standard materials: copper foil for printed circuit board pattern, flexible core connecting circuit copper foil and cover layer encapsulating external circuit layer, which has the same function as soldermask on rigid flexible PCB

Some flexible FPC designs may also require adhesive reinforcement to reinforce supporting components/FPC connector area, adhesive glue (double-sided pressure sensitive adhesive glue) to connect flexible FPC to steel sheet reinforcement or FR4 reinforcement, or shielding film for EMI sensitive applications.

For each of the above materials, there are multiple options with different maximum operating temperature capabilities. For typical -40°C to 85°C requirements, all standard flexible materials can be used without additional material-related considerations. At higher temperatures, materials and structures will need to change.

2-layer flexible FPC circuit board structure

flexible pcb

3-layer flexible FPC circuit board structure

Flexible FPC adhesive

Flexible adhesive is used in three specific areas: coverlay connection, interlayer lamination and reinforcement connection for 3-layer or higher designs.

Three types of adhesives can be used: acrylic-based, modified flexible epoxy resin and polyimide coating. Each has a different continuous operating temperature rating.

Acrylic adhesives have the lowest temperature rating and are used in standard applications without any significant high temperature requirements. Epoxy-based adhesives are rated for 130–140°C, and polyimide-based adhesives are rated for 220°C+.

Polyimide-based adhesives are used in medical applications that require autoclaving. Downhole drilling applications with a 200°C continuous temperature specification require polyimide-based adhesives.

Polyimide adhesives require very high temperatures for lamination. While acrylic and epoxy adhesives laminate in the 180-200°C range, polyimide adhesives require 307-316°C. Not all flexible FPC board manufacturers have high temperature lamination capabilities. Polyimide-based adhesives are also much more expensive than acrylic or epoxy adhesives of comparable cost.

We recommend that adhesive requirements be specified in the fabrication drawing notes per the IPCF specifications as follows:

Acrylic Adhesives: IPC4203/18

Epoxy Adhesives: IPC4203/19

Polyimide Adhesives: IPC4203A/24

Flexible Circuit Board Adhesives and Reinforcements

Flexible FPC circuit board adhesives and reinforcements are a very broad category of adhesives. Most have fairly high operating temperatures, but bond strength will vary with temperature. Adhesion is not usually an important requirement for flex applications, as the adhesive on the flex is not subject to any high forces. Below are the specifications for the most commonly used 3M 467MP Adhesive.

3M 467MP Adhesive Specifications

For reinforcement applications, the only potential temperature issue that may occur is with FR4 reinforcements, in addition to the adhesive requirements discussed previously. Stainless steel, aluminum, and polyimide reinforcements are rated for temperatures far exceeding the requirements. For FR4 reinforcements operating at the same temperature, we recommend following the same FR4 requirements.

Flexible pcb Circuit Board EMI Shielding

EMI shielding can be achieved using EMI shielding films or additional solid or cross-hatched copper layers. Currently, silver paste shielding is rarely used in today's designs. Copper layer shielding provides the highest possible operating temperature and will be temperature rated depending on the adhesive used, as this will require a 3-layer or more flexible structure.

Flexible Circuit with Solid Copper EMI Shielding Layer

The negative impact of copper layer shielding is a significant increase in bending thickness, resulting in reduced flexibility and bending ability, and increased part cost. EMI shielding film is the preferred solution for flexibility/bending ability and cost effectiveness, but is limited to 125°C maximum continuous operating temperature.

EMI shielding film is laminated to the surface of the part in a similar method to coverlays. The adhesive used in the shielding film is used to attach the film and electrically connect it to the ground grid within the flexible circuit. Exceeding the operating temperature will increase the contact resistance and may compromise the effectiveness of the shielding. For temperatures above 125°C, the only viable option is an additional copper shielding layer.

We hope to help electronic engineers who may encounter high temperature issues with flexible FPC when designing FPC circuit boards. If you have any questions, please feel free to contact iPCB. We look forward to the opportunity to discuss your specifications and review your flexible PCB design to ensure it meets the operating temperature requirements for your product.