Flexible Printed Circuit Board (FPC) is a type of circuit board made with a flexible substrate, typically using high-performance materials such as polyester film, polyimide (PI), or polyamide (PA). Compared to traditional rigid boards, FPC offers flexibility and bendability, making it ideal for electronic devices and products that require bending or complex shapes. It features high wiring density, lightweight, thin profile, and excellent flexibility. Due to its lightweight, thinness, and ability to bend and fold freely in three-dimensional space, FPC is highly favored.

FPC technology was developed in the 1970s in the United States to advance aerospace rocket technology. It is a type of highly reliable and flexible printed circuit made from a polyester film (PET) or polyimide (PI) substrate. By embedding circuit designs onto flexible, thin plastic sheets, FPCs can pack a large number of precision components into narrow and confined spaces, forming bendable flexible circuits. These circuits can be bent and folded at will, are lightweight, compact, have good heat dissipation, and are easy to install, breaking through traditional interconnection technology. The materials that make up the structure of flexible circuits include insulating films, conductors, and adhesives.

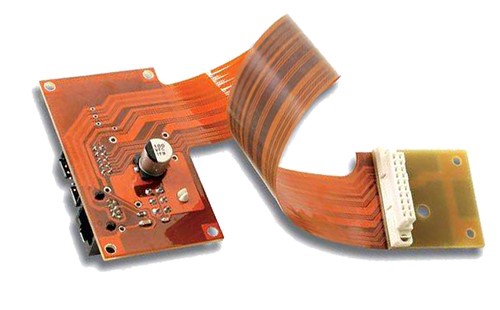

FPC is not only flexible but is also a key design method for forming three-dimensional circuit structures. When paired with other electronic product designs, FPC can support a wide variety of applications. For traditional PCBs, the circuit board is typically flat unless a 3D shape is molded. Therefore, FPC is one of the best solutions for maximizing the use of three-dimensional space. A common way to extend space in PCBs is by using slots and interface cards, but Flexible Printed Circuit Board can achieve similar structures through connector design, offering more flexible direction adjustments. Using a single FPC connection, two PCBs can be connected into a parallel circuit system or bent at any angle to suit the shape of different products.

FPC can save internal space in electronic products to a certain extent, making assembly and processing more flexible. For example, in smartphones, the LCD/OLED, and AMOLED display panels are connected via FPC. Similarly, FPC is widely used in laptops, digital cameras, as well as in the medical, automotive, and aerospace fields.

The FPC substrate consists mainly of the following three materials:

1. Insulation Layer

The insulation layer in the FPC substrate is primarily achieved by coating polyimide film or other insulating materials on both sides of the conductive layer. Its role is to isolate the conductive layer, prevent short circuits and interference, and provide electrical insulation. Common insulation materials include polyimide film (PI) and polyester film (PET). PI film has excellent heat resistance and can operate at high temperatures, typically enduring temperatures from -200°C to +300°C. This makes FPC suitable for high-temperature environments and applications requiring thermal stability. PET is more affordable than PI but lacks dimensional stability and heat resistance, making it unsuitable for SMT or wave soldering. It is commonly used for detachable connectors and has gradually been replaced by PI film. The typical thicknesses of PI films are 1/2 mil, 1 mil, and 2 mil.

2. Conductive Layer

The conductive layer of the FPC substrate is generally made of copper foil, which has excellent conductivity and processability, providing the necessary conductive pathways for the circuit board. The thickness of the conductive layer can vary depending on the application, with common thicknesses being 1/3 oz, 1/2 oz, and 1 oz.

3. Adhesive Layer

The adhesive layer in the Flexible Printed Circuit Board substrate, often referred to as the glue layer, is made from epoxy resin (Epoxy). Its main role is to secure the conductive layer and improve insulation strength and mechanical properties. Common adhesive layer thicknesses are 13um and 20um.

Key Features and Applications of FPC:

1. Flexible and Thin Design

Made from a flexible substrate, FPC can bend and flex without compromising performance. This makes FPC suitable for electronic devices with limited space and complex shapes, such as wearable devices, foldable phones, and camera modules.

2. Lightweight

Due to the use of flexible substrates, FPC is lighter than traditional rigid boards. This is advantageous in applications where product weight is critical, such as aerospace and portable electronic devices.

3. High-Density Connectivity

FPC allows for high-density electrical connections and wire routing, enabling the design of complex circuits. This makes FPC particularly suitable for applications requiring numerous connections and intricate wiring, such as flat panel displays and digital cameras.

4. Vibration and Impact Resistance

Thanks to its flexible nature, FPC has good resistance to vibration and impact, making it ideal for applications requiring high reliability and resistance to interference, such as automotive electronics and medical equipment.

5. Automated Manufacturing

FPC is often manufactured using similar processes to printed circuit boards (PCBs), which supports a degree of automation in production and improves efficiency.

Applications of Flexible Printed Circuit Board Include:

Mobile Devices: Foldable phones, tablets, etc.

Medical Devices: Medical sensors, imaging equipment, etc.

Automotive Electronics: In-car displays, cameras, etc.

Aerospace: Avionics, spacecraft internal connections, etc.

Consumer Electronics: Digital cameras, headphones, smartwatches, etc.

Flexible printed circuits were developed in the 1970s in the United States to support the development of aerospace rocket technology. Made from polyester or polyimide substrates, they offer high reliability and excellent flexibility. By embedding circuit designs into flexible plastic sheets, FPC allows for the stacking of numerous precision components in small spaces, forming flexible circuits that can bend, fold, and offer lightweight, compact, and easy-to-install solutions. This technology has revolutionized traditional interconnection methods, with key materials being insulating films, conductors, and adhesives.

FPC is the only solution that meets the demands for miniaturization and mobility in electronic products. It significantly reduces the size and weight of electronic devices, supporting their development toward high density, miniaturization, and high reliability.