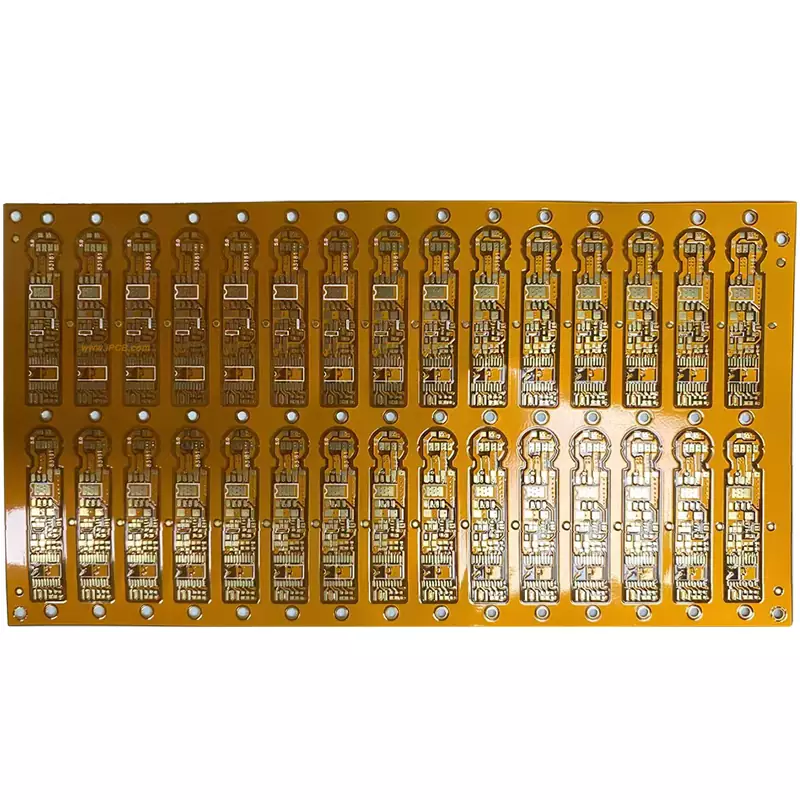

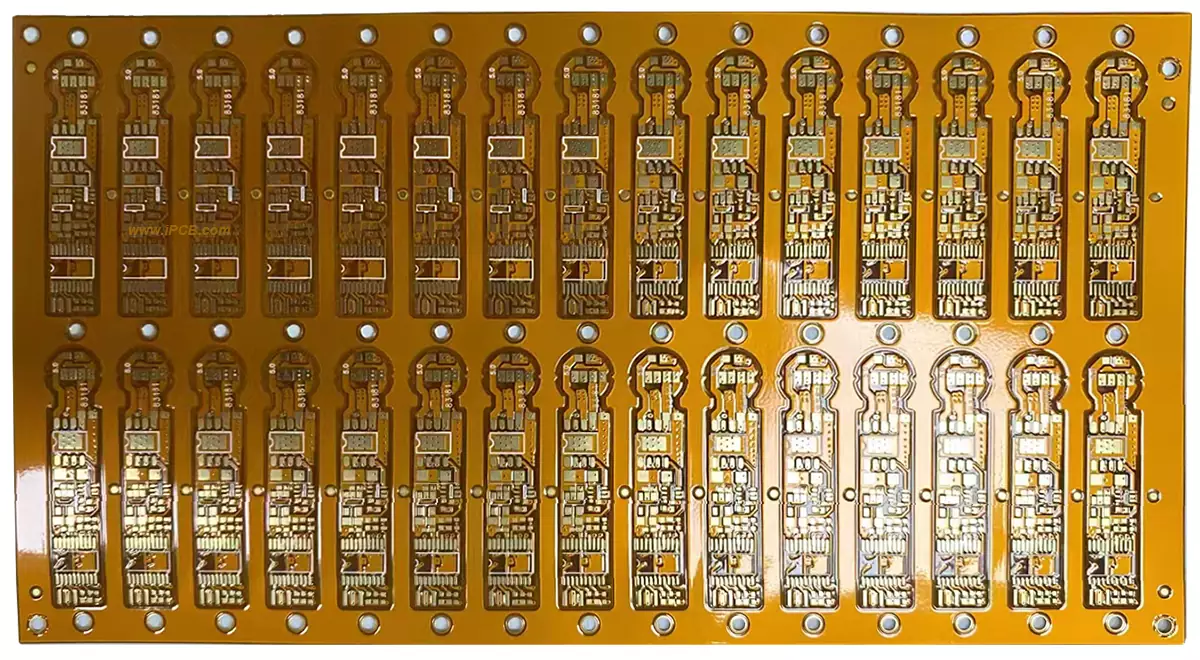

Product Name: FPC flexible circuit board

Material: PI, Polyimide

Material brands: Taihong, DuPont, Shengyi

Layer: 2L

Size: Maximum length of 12M

FPC thickness: 0.15mm

Copper thickness: 0.035mm

Surface treatment: ENIG

Minimum line width/spacing: 2/2 mil

Application: Automobiles, consumer electronics

FPC (Flexible Printed Circuit) is a type of circuit board made of flexible copper-clad laminate as the substrate. It is used as a medium for signal transmission and is applied to the connection of electronic products. It has the characteristics of high wiring assembly density, good flexibility, lightweight, and flexible process. FPC can generally be divided into single-layer FPC, double-layer FPC, and multi-layer FPC.

With the development of electrification and intelligence in automobiles, FPC's advantages in flexibility, weight reduction, and high degree of automation are further reflected. The usage of FPC in the automotive field continues to increase, and its applications cover the three major power control systems of headlights, display modules, BMS/VCU/MCU, sensors, advanced auxiliary systems, and other related scenarios. The rapid development of new energy vehicles has driven a significant increase in demand for FPC used in vehicle power batteries.

The collection line is an important component required for the BMS system of new energy vehicles, which monitors the voltage and temperature of the new energy power battery cells. Connect data collection and transmission with built-in overcurrent protection function; Protect the battery cells of the car power battery and automatically disconnect them in case of abnormal short circuits.

Previously, the power battery collection line for new energy vehicles used a traditional copper wire harness solution. The conventional harness was made of copper wire surrounded by plastic. When connecting the battery pack, each harness reached an electrode. When there were many current signals in the power battery pack, many harnesses were needed to cooperate, which greatly occupied the space. In the pack assembly process, traditional wiring harnesses rely on workers manually fixing the ports to the battery pack, resulting in a low degree of automation.

Compared to copper wire harnesses, FPC has outstanding advantages in terms of safety, lightweight, and well-organized layout due to its high integration, ultra-thin thickness, and ultra flexibility. In addition, FPC has a thin thickness, customized battery pack structure, and can be directly placed on the battery pack by a robotic arm during assembly. It has a high degree of automation and is suitable for large-scale production. The trend of FPC replacing copper wire harnesses is clear.

Due to the high cost of small-scale production in the early stages of the industry and the high reliability requirements in the automotive electronics field, most power battery companies are still in a wait-and-see attitude. With the excellent performance demonstrated by FPC and the rapid cost reduction brought about by large-scale production, the process of FPC replacing traditional wire harnesses has significantly accelerated. Public information shows that BYD, Tesla, Guoxuan High tech, AVIC Lithium Battery, Tafel, Xinwangda, Funeng and other companies have also started to use FPC. At present, FPC scheme has become the main choice for the vast majority of new energy vehicle models.

FPC integrates with CCS (Cells Contact System, integrated busbar, wiring harness board integrated components). CCS products are composed of flexible PCB, plastic structural components, copper aluminum bars, etc. The copper aluminum bars connect multiple cells in series and parallel through laser welding, while the FPC is connected to the copper aluminum bars and plastic structural components to form electrical connections and signal detection structural components.

FPC (Flexible Printed Circuit)

iPCB strictly controls the quality level of FPC in accordance with IPC standards to ensure the qualified rate of flexible PCB shipment quality. Using high-quality raw materials to ensure product quality from the source.

Substrate: Taihong, DuPont, Shengyi

PI reinforcement: Taihong

Cover film: Taihong, DuPont, Shengyi

Differentiated process capability to meet the requirements of various soft and hard bonding boards.

Minimum line width/spacing: 0.05mm/0.05mm

Minimum via pad: 0.3mm; Coverage surface bit tolerance: 0.15mm

External tolerance of soft hard bonding plate: 0.05mm; Maximum number of layers for soft hard composite board: 2-54 layers

Pitch tolerance:+/-0.05mm; Minimum Thunderbolt Hole: 0.1mm

Maximum external dimensions: 480mm * 1000mm

We can meet the requirements of fast and efficient delivery. If you have any design or production needs for Rigid Flex PCB or FPC Flexible Printed Circuit, we can assist you.

Product Name: FPC flexible circuit board

Material: PI, Polyimide

Material brands: Taihong, DuPont, Shengyi

Layer: 2L

Size: Maximum length of 12M

FPC thickness: 0.15mm

Copper thickness: 0.035mm

Surface treatment: ENIG

Minimum line width/spacing: 2/2 mil

Application: Automobiles, consumer electronics

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.