FPC connectors were developed in response to the market trend toward miniaturization and to meet the challenges of this expanding market: the urgent need for smaller pin spacing or pitch space, thinner thickness and lighter weight interconnect solutions.

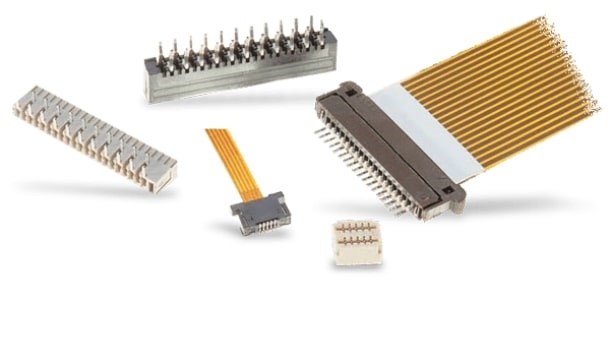

FFC connectors are commonly used to connect ribbon flat flexible cables (FFCs) to PCB circuits in wire-to-board applications, and they can also be used in wire-to-wire configurations. These connectors have a high density, very narrow form factor and fit into tight spaces.

They are commonly used in consumer applications such as laptops, cameras, computer equipment, home appliances and cell phones. Single or dual row connector housings are typically made of flexible plastics, polymers, engineered rubbers or films that surround embedded metal connectors. A variety of locking styles are available.

FPC Connector Structure and Use

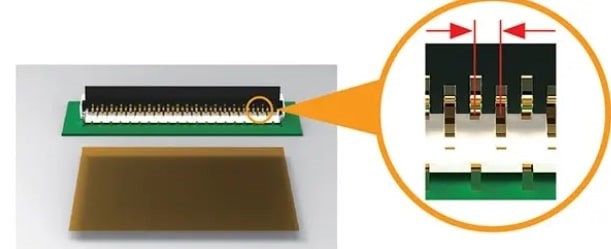

FPC connector is characterized by one end and PCB welding connection (more SMT welding), the other end and FPC plug, and FPC connector designed to lock the device so that the FPC and FPC connector lock, to maintain a certain degree of contact reliability. So the connector's plastic body and terminals as well as the card lock parts with strict requirements.

In order to meet the requirements of the SMT process, the entire product terminal welding area are strictly required to have good flatness and coplanarity, usually the industry norms for coplanarity 0.10max. Otherwise, it will lead to poor welding with the PCB and affect the use of the product. One of the main reasons designers choose FFC/FPC connectors is that, when used with flexible cables, they offer a higher degree of flexibility than traditional rigid circuit boards.

FPC Connectors

How to use FPC connectors:

1. Preparation Before using FPC connectors, make sure that the circuit board (PCB) and connectors have been cleaned and are free of dust and foreign objects. In addition, it is necessary to prepare appropriate tools, such as tweezers, flux and so on.

2. Connector Installation (1) Insert the FPC connector into the connector holder on the circuit board. (2) Gently lift the FPC connector with your thumb or index finger to keep it parallel. (3) Align the exposed conductive material side of the FPC connector, face down, with the contact points on the circuit board. (4) Gently rotate the actuator downward until tight. Make sure that the inserted FPC connector is not moved and keep it fully inserted.

3. Connector Removal (1) To remove the FPC connector, lift the actuator first. (2) Withdraw the FPC connector carefully to avoid damaging the board and connector.

Design fpc connector row wire function

The row wire in FPC connector is a new type of data information cable, which is pressed by PET or other insulating layer materials and thin tinned flat copper core wire according to the new technology automated mechanical production line. However, its wires have good electrical properties, electrode chemical properties and good temperature resistance.

In addition, the row of wires has more stability and quality of installation, at the same time, the row of wires can also reduce the hardware required for internal connection. For example, in a typical connector package format, the commonly used spot welds, relays, bottom wires and cables are necessary. Therefore, when using FPC connectors, it is important to ensure the stability and quality of their installation.

FPC Connectors

FPC connectors have the following characteristics:

First, FPC connectors can provide better connection stability, and faster connection speed. This means that the FPC connector can quickly connect the FPC flexible board and other equipment, greatly improving production efficiency.

Secondly, FPC connectors offer good reliability and stability, thanks to their strong mechanical properties and chemical stability. It can withstand different environmental conditions such as vibration, temperature changes and mechanical shock.

Thirdly, the FPC connector adopts precise design and processing technology to ensure the mechanical and electrical properties of the connector, thus ensuring the stability and reliability of the connection.

Application of FFC/FPC connectors

The role of FPC connector products and the scope of application of FPC connector products are used to connect circuit boards (PCB) and flexible printed circuit boards (FPC), so that they realize the role of mechanical and electrical connections. Today's FPC connectors are mainly used in LCD and LED liquid crystal displays, scanners, digital cameras, game consoles, tablet PCs, laptops, car theaters and other electronic devices.

FPC connector products are also widely used in audio, digital machines, video cameras, car stereos, televisions, typewriters, calculators, cash registers, telephones, CD-ROMs, VCDs, DVDs, photocopiers, printers, wireless instrumentation and other equipment. It can be said that FPC connectors are an indispensable part of the development of modern electronic equipment.

In short, FPC flexible boards and their connectors are increasingly widely used in electronic equipment, the advantages of which lie in flexible, reliable, efficient, and can help equipment to achieve more precise and efficient performance. In the future, the market potential of FPC flexible boards and their connectors will be further released, becoming one of the main trends in electronic product design.